Your Ultimate Guide to Sourcing Wedding Dresses Empire Cut

Guide to Wedding Dresses Empire Cut

- Introduction: Navigating the Global Market for wedding dresses empire cut

- Understanding wedding dresses empire cut Types and Variations

- Key Industrial Applications of wedding dresses empire cut

- Strategic Material Selection Guide for wedding dresses empire cut

- In-depth Look: Manufacturing Processes and Quality Assurance for wedding dresses empire cut

- Manufacturing and Quality Assurance for Empire Cut Wedding Dresses: A Detailed Overview

- Comprehensive Cost and Pricing Analysis for wedding dresses empire cut Sourcing

- Spotlight on Potential wedding dresses empire cut Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for wedding dresses empire cut

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the wedding dresses empire cut Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of wedding dresses empire cut

- Strategic Sourcing Conclusion and Outlook for wedding dresses empire cut

Introduction: Navigating the Global Market for wedding dresses empire cut

The empire cut wedding dress remains a perennial favorite in bridal fashion, blending timeless elegance with flattering silhouettes that appeal across diverse markets. For international B2B buyers—particularly from dynamic regions such as Africa, South America, the Middle East, and Europe—understanding the nuances of this style is essential to capitalize on growing consumer demand and regional preferences. Its high waistline and flowing skirt create a universally flattering shape that resonates with brides seeking sophistication and comfort, making it a versatile product for wholesalers and retailers alike.

This comprehensive guide is designed to equip buyers with actionable insights into the global empire cut wedding dress market. It covers a broad spectrum of critical topics including the variety of empire cut styles, selection of premium fabrics, manufacturing best practices, and stringent quality control measures. Additionally, it offers an in-depth analysis of reliable suppliers, cost structures, and emerging market trends tailored for international trade.

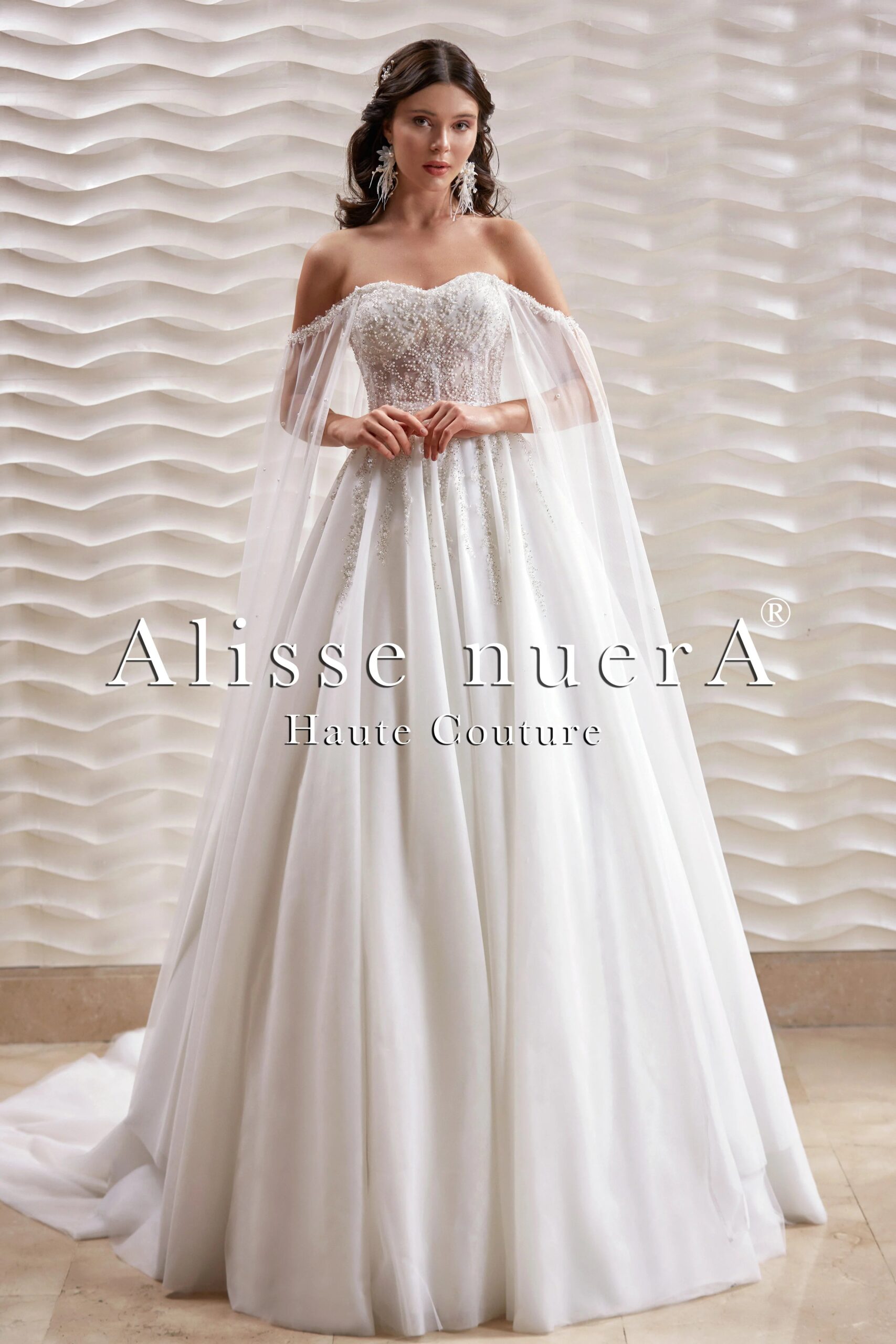

Illustrative Image (Source: Google Search)

By navigating this guide, buyers will gain the confidence to make informed sourcing decisions, optimize inventory with styles that meet regional tastes, and establish strong partnerships with manufacturers who deliver quality and value. Whether sourcing for boutique bridal shops in Cairo, large-scale distributors in São Paulo, or fashion retailers in Warsaw and Hanoi, this resource ensures a strategic approach to expanding product offerings with empire cut wedding dresses that captivate and convert.

Understanding wedding dresses empire cut Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Classic Empire Cut | High waistline under bust, flowing A-line skirt, minimal embellishment | Bridal boutiques, formal wedding wear retailers | Timeless appeal and broad market; may require premium fabrics |

| Lace-Embellished Empire | Empire silhouette with intricate lace overlays or bodice | Luxury bridal designers, boutique wholesalers | High perceived value; higher cost and delicate handling needed |

| Bohemian Empire Cut | Lightweight fabrics, often chiffon or tulle, relaxed styling | Destination wedding suppliers, casual bridal collections | Popular in warm climates; may have limited formal appeal |

| Modern Empire with Embellishments | Empire cut with added beading, sequins, or embroidery | Mid to high-end bridal wholesalers, fashion-forward retailers | Trendy and eye-catching; complexity increases production time |

| Plus-Size Empire Cut | Empire cut designed with additional support and stretch fabrics | Inclusive bridal retailers, specialty plus-size boutiques | Expands market reach; requires careful sizing and fabric choice |

Classic Empire Cut

The classic empire cut wedding dress features a simple, high waistline just below the bust with a flowing A-line skirt that gently skims the body. This type suits a wide range of body shapes, making it a versatile option for various markets globally, including Africa and Europe. For B2B buyers, this style represents a core product line with consistent demand. Sourcing quality fabrics and maintaining timeless designs can ensure steady wholesale sales to bridal salons and department stores.

Lace-Embellished Empire

This variation incorporates delicate lace overlays or lace bodices, adding a romantic and luxurious touch to the traditional empire silhouette. It appeals strongly to upscale bridal boutiques and luxury markets, especially in regions like the Middle East and South America, where intricate craftsmanship is valued. B2B buyers should consider the higher production costs and the need for skilled artisans to maintain quality, balanced against the ability to command premium pricing.

Bohemian Empire Cut

Characterized by soft, flowing fabrics such as chiffon or tulle and a relaxed, less structured fit, the bohemian empire cut is ideal for destination weddings and casual bridal collections. This style resonates well in warm climates and emerging markets like Vietnam and parts of Africa. For wholesalers, stocking lightweight, easy-to-ship designs can open new market segments focused on comfort and natural aesthetics, though these dresses may be less suited for formal or traditional wedding settings.

Modern Empire with Embellishments

Adding modern flair, these empire cut dresses feature embellishments like beading, sequins, or embroidery that elevate the silhouette with sparkle and texture. This variation targets fashion-forward bridal retailers and mid to high-end wholesalers looking to attract younger or trend-conscious brides. Buyers should evaluate production timelines and quality control due to the complexity of embellishments but can leverage these features for higher margins and differentiation.

Plus-Size Empire Cut

Designed specifically for plus-size brides, this variation maintains the classic high waistline but integrates supportive structures and stretch fabrics to enhance comfort and fit. This segment is growing rapidly, particularly in Europe and South America, where inclusivity is becoming a market priority. B2B buyers investing in plus-size empire cuts can expand their customer base but must carefully select suppliers with expertise in plus-size garment construction and durable, flattering materials.

Related Video: Large Language Models (LLMs) – Everything You NEED To Know

Key Industrial Applications of wedding dresses empire cut

| Industry/Sector | Specific Application of wedding dresses empire cut | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Bridal Retail & Boutiques | Offering empire cut wedding dresses as a core style in bridal collections | Meets demand for timeless, flattering silhouettes; broad market appeal | Fabric quality, design authenticity, size inclusivity, supplier reliability |

| Wedding Event Planning | Providing dress recommendations and rentals featuring empire cut styles | Enhances client satisfaction with versatile, elegant dress options | Inventory variety, rental durability, style trend alignment |

| Fashion Manufacturing | Producing empire cut dresses for wholesale distribution | Capitalizes on steady demand for classic bridal wear; scalable production | High-quality materials, skilled craftsmanship, compliance with fashion trends |

| Online Wedding Marketplaces | Listing empire cut dresses for global B2B wholesale buyers | Expands reach to international retailers, especially in emerging markets | Competitive pricing, logistics support, clear product specifications |

| Wedding Accessories & Complementary Products | Designing accessories tailored to empire cut dresses (belts, boleros) | Creates cross-selling opportunities, enhances overall bridal look | Compatibility with dress styles, quality matching, supplier coordination |

Bridal Retail & Boutiques

Bridal retailers and boutiques worldwide, especially in Africa, South America, the Middle East, and Europe, incorporate empire cut wedding dresses as a staple offering due to their universally flattering silhouette and historical appeal. These dresses attract a broad demographic, including brides seeking elegant, body-flattering options that emphasize the bust while softening the waist and hips. Retailers must prioritize sourcing from manufacturers who provide high-quality fabrics and craftsmanship, ensuring durability and comfort. For international buyers, especially in emerging markets like Egypt or Vietnam, reliable supply chains and flexible sizing are critical to meet diverse customer needs.

Wedding Event Planning

Event planners often recommend or provide empire cut wedding dresses as part of their wedding packages, recognizing their versatility and flattering fit on various body types. This style suits many cultural preferences across regions such as the Middle East and South America, where modesty and elegance are valued. Planners benefit by offering rental or purchase options that satisfy client expectations for comfort and style. Key sourcing considerations include maintaining a diverse inventory with durable fabrics suitable for multiple uses and ensuring that dress styles align with current trends and traditional preferences.

Fashion Manufacturing

Manufacturers specializing in bridal wear capitalize on the consistent demand for empire cut dresses by producing these gowns in bulk for wholesale markets. Their production must balance traditional design elements with modern fabric technology to appeal to international markets, including Europe and Africa, where quality and style trends evolve rapidly. Buyers from these regions seek manufacturers who can deliver high-quality, handcrafted details with efficient turnaround times. Additionally, adherence to international quality standards and certifications enhances trust and facilitates smoother import/export processes.

Illustrative Image (Source: Google Search)

Online Wedding Marketplaces

Online B2B platforms that list empire cut wedding dresses enable international buyers, particularly from fast-growing markets in Africa and South America, to access a wide range of styles at competitive prices. These marketplaces help retailers and boutiques diversify their offerings without the need for large upfront inventory investments. For buyers, critical considerations include transparent product descriptions, accurate sizing charts, and reliable logistics solutions to handle cross-border shipping. Ensuring supplier responsiveness and after-sales support is also vital to maintain business continuity.

Wedding Accessories & Complementary Products

Suppliers of wedding accessories tailor complementary items such as belts, boleros, and shawls specifically designed to enhance the empire cut silhouette. This creates valuable cross-selling opportunities for bridal shops and online retailers targeting international markets, where brides often seek complete coordinated looks. For B2B buyers, sourcing accessories that perfectly match the fabric and style of empire cut dresses is essential to maintain aesthetic harmony and customer satisfaction. Close collaboration with dress manufacturers ensures accessory collections meet the evolving demands of brides across diverse cultural contexts.

Related Video: Introduction to Uses and Gratifications Theory

Strategic Material Selection Guide for wedding dresses empire cut

Analysis of Common Materials for Empire Cut Wedding Dresses

1. Satin

Key Properties: Satin is a smooth, glossy fabric typically made from silk, polyester, or nylon. It has a luxurious sheen and a soft texture, with moderate durability and good drape. Satin is breathable but can be less resistant to abrasion and prone to snagging.

Pros & Cons: Satin offers an elegant, high-gloss finish that enhances the classic empire cut silhouette, making it ideal for formal wedding gowns. It is relatively easy to dye and maintain a rich color. However, satin can be costly if made from silk and requires careful handling during manufacturing to avoid surface damage. Polyester satin variants are more affordable but may feel less breathable.

Impact on Application: Satin’s smooth surface complements the empire cut’s flowing skirt and fitted bodice, providing a flattering silhouette. It suits climates with moderate temperatures but may be less comfortable in very hot or humid regions due to lower moisture-wicking properties.

Considerations for International Buyers: For buyers in Africa and the Middle East, where warmer climates prevail, polyester satin blends may be preferred for affordability and durability but should be balanced against breathability concerns. European and South American markets often demand higher quality silk satin complying with standards such as OEKO-TEX for chemical safety. Compliance with ASTM textile standards and local import regulations should be verified, especially for large wholesale orders.

2. Chiffon

Key Properties: Chiffon is a lightweight, sheer fabric made from silk, nylon, or polyester fibers. It has a slightly rough texture and excellent drape, offering a flowing, ethereal look. Chiffon is breathable but delicate and prone to tearing.

Pros & Cons: Chiffon is ideal for empire cut dresses that emphasize softness and movement, enhancing the gathered skirt’s fluidity. It is lightweight and comfortable for warm climates, making it popular in Middle Eastern and African markets. However, chiffon is more challenging to sew, requiring skilled labor, and it is less durable than heavier fabrics.

Impact on Application: The fabric’s transparency often necessitates lining, increasing production complexity and cost. Chiffon’s delicate nature means it is less suited for high-traffic retail environments without careful packaging and handling.

Considerations for International Buyers: Buyers from Vietnam and Egypt should consider chiffon’s maintenance requirements and the availability of skilled manufacturing partners. Compliance with international textile safety standards (e.g., REACH in Europe) is crucial. Chiffon sourced from reputable suppliers with certifications ensures consistent quality for wholesale.

3. Organza

Key Properties: Organza is a crisp, sheer fabric usually made from silk or synthetic fibers like polyester. It holds shape well, providing volume without heaviness, and has moderate resistance to wrinkles and abrasion.

Pros & Cons: Organza is excellent for empire cut dresses requiring structure in the skirt or bodice, creating a regal and voluminous look. It is more durable than chiffon but less soft, which may affect comfort. Organza is more expensive and requires precision in cutting and sewing.

Impact on Application: Its stiffness supports the empire silhouette’s gathered skirt, ideal for formal weddings with elaborate styling. Organza performs well in varied climates but may feel less breathable in hot regions.

Considerations for International Buyers: European and South American buyers often prefer silk organza for premium collections, while synthetic organza is popular in African and Middle Eastern markets for cost efficiency. Confirming compliance with ASTM or DIN textile standards and verifying the origin of raw materials is recommended for import/export consistency.

4. Lace (Embroidered or Appliqué)

Key Properties: Lace is a decorative openwork fabric, often made from cotton, silk, or synthetic fibers. It adds intricate texture and detail to wedding dresses, especially on bodices and sleeves.

Pros & Cons: Lace enhances the empire cut dress by adding delicate embellishment and a romantic aesthetic. It is versatile and can be combined with other fabrics like satin or chiffon. However, lace can be fragile, expensive, and requires skilled craftsmanship to integrate seamlessly.

Impact on Application: Lace overlays or appliqués are well-suited for buyers targeting premium bridal markets in Europe and South America, where detailed craftsmanship is valued. In warmer climates, lace combined with breathable linings can maintain comfort.

Considerations for International Buyers: Buyers in Egypt and Vietnam should source lace that meets international quality standards and is compatible with local manufacturing capabilities. Lace’s delicate nature demands careful logistics and packaging. Compliance with international textile safety and labeling standards is essential for retail success.

Summary Table of Materials for Empire Cut Wedding Dresses

| Material | Typical Use Case for wedding dresses empire cut | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Satin (Silk or Polyester) | Elegant, smooth bodices and flowing skirts in formal weddings | Luxurious sheen and smooth texture enhancing silhouette | Prone to snagging; silk satin can be costly and less breathable | Medium to High (Silk), Low to Medium (Polyester) |

| Chiffon | Lightweight, flowing skirts for ethereal, soft looks | Excellent drape and breathability suitable for warm climates | Delicate, difficult to sew, requires lining | Medium |

| Organza | Structured skirts and bodices for volume and formality | Holds shape well, adds volume without heaviness | Less soft, can be uncomfortable in hot climates | Medium to High |

| Lace (Embroidered/Appliqué) | Decorative overlays and bodice embellishments | Adds intricate detail and romantic texture | Fragile, requires skilled labor, higher cost | Medium to High |

This guide aims to assist international B2B buyers in selecting materials that align with their target markets’ climatic conditions, quality expectations, and manufacturing capabilities, ensuring competitive and compliant product offerings in the empire cut wedding dress segment.

In-depth Look: Manufacturing Processes and Quality Assurance for wedding dresses empire cut

Manufacturing and Quality Assurance for Empire Cut Wedding Dresses: A Detailed Overview

The production of empire cut wedding dresses involves a meticulous manufacturing process combined with rigorous quality assurance protocols to ensure the final product meets high standards expected by international B2B buyers. Understanding these processes equips buyers—especially from regions such as Africa, South America, the Middle East, and Europe—with the insight needed to select reliable suppliers and maintain consistency in their product offerings.

Manufacturing Process: Key Stages and Techniques

The creation of an empire cut wedding dress typically follows four main stages, each critical to achieving the signature silhouette and quality:

-

Material Preparation

– Fabric selection: High-quality fabrics such as silk, chiffon, satin, or lace are sourced, often from established European textile mills to meet premium standards.

– Inspection: Incoming materials undergo initial quality checks for color consistency, texture, tensile strength, and flaw detection before cutting.

– Pre-treatment: Fabrics may be washed, dyed, or treated for shrinkage and durability to ensure longevity and comfort. -

Forming and Cutting

– Pattern making: Skilled designers draft precise patterns that account for the empire waistline—fitted bodice ending just below the bust—and flowing skirt.

– Cutting: Automated cutting machines or manual cutters slice fabrics according to patterns, maximizing material utilization and minimizing waste.

– Detailing: Delicate elements like pleats or gathers under the bust are carefully prepared to maintain the dress’s characteristic high-waistline silhouette.

-

Assembly

– Bodice construction: Tailored to fit snugly just below the bust, often involving darts, boning, or lining for structure.

– Skirt attachment: The skirt is attached with gathers or pleats, ensuring a smooth flow that flatters various body shapes.

– Handcrafting: Approximately 40-60% of the assembly—especially embellishments, lace application, and finishing seams—is done manually to ensure precision and reduce defects.

– Accessory integration: Incorporation of zippers, buttons, and decorative elements like beads or embroidery is performed with care to preserve aesthetic and functional quality. -

Finishing

– Pressing and steaming: Final pressing ensures the dress holds its shape and the fabric drapes elegantly.

– Trimming and cleaning: Loose threads and any residual manufacturing marks are removed.

– Packaging: Dresses are carefully folded or hung with protective covers to prevent damage during transit.

Quality Assurance Framework

Quality assurance (QA) for empire cut wedding dresses is a multi-layered process aligned with international standards and industry-specific requirements, ensuring products meet buyer expectations and regulatory compliance.

Relevant International and Industry Standards

- ISO 9001: Many reputable manufacturers adhere to ISO 9001 quality management systems, which promote consistent production processes, continuous improvement, and customer satisfaction.

- OEKO-TEX Standard 100: Certification ensures textiles are free from harmful substances—a key consideration for sensitive bridal wear.

- CE Marking: Although not always mandatory for apparel, CE compliance may be relevant if accessories incorporate electronic or safety components.

- Local compliance: Suppliers often align with regional standards applicable to export destinations, such as the EU’s REACH regulations or Middle Eastern import requirements.

Quality Control Checkpoints

-

Incoming Quality Control (IQC)

– Examines raw materials and components for defects before production starts.

– Includes fabric inspection for colorfastness, weave integrity, and contamination.

– Verification of accessory quality (zippers, beads, threads). -

In-Process Quality Control (IPQC)

– Continuous monitoring during assembly stages.

– Checks for stitching quality, seam strength, fit accuracy of bodice and skirt.

– Verification of embellishment placement and consistency.

– Use of sample inspections at batch intervals to catch defects early. -

Final Quality Control (FQC)

– Comprehensive inspection of completed dresses.

– Includes visual checks, measurement verification against specifications, and functional testing (e.g., zipper operation).

– Spot checks for fabric flaws, stains, or finishing defects.

– Packaging inspection to ensure protection during shipping.

Common Testing Methods

- Tensile and seam strength testing: Ensures durability of stitches and fabric under stress.

- Colorfastness tests: Includes washing, rubbing, and light exposure to confirm color stability.

- Dimensional inspections: Verify that key measurements (bustline, waistline, skirt length) adhere to design specifications.

- Hand feel and drape analysis: Evaluated by experienced QC personnel to guarantee fabric quality and garment silhouette integrity.

Verifying Supplier Quality: Actionable Strategies for B2B Buyers

For buyers in Africa, South America, the Middle East, and Europe, verifying supplier quality is critical to secure consistent, high-quality empire cut wedding dresses. Consider these approaches:

- Factory Audits: Conduct or commission on-site inspections to evaluate manufacturing capabilities, equipment modernity, and adherence to quality standards. Audits should cover material sourcing, production workflows, and worker skill levels.

- Review of Quality Documentation: Request ISO 9001 certificates, OEKO-TEX reports, and inspection records (IQC, IPQC, FQC) to confirm compliance.

- Third-Party Inspections: Employ independent inspection agencies for unbiased quality verification before shipment. This is especially valuable for remote buyers or those sourcing from emerging markets like Vietnam or Egypt.

- Sample Orders: Procure sample dresses to personally assess fit, finish, and fabric quality before committing to bulk purchases.

- Supplier Communication: Establish clear quality expectations and detailed specifications upfront. Regular dialogue helps preempt misunderstandings and supports continuous quality improvement.

QC and Certification Nuances for International Markets

- Africa & South America: Buyers should emphasize fabric durability and climate-appropriate treatments (e.g., moisture resistance) due to diverse weather conditions. Certifications related to sustainable textiles (e.g., GOTS) may also appeal to growing eco-conscious markets.

- Middle East: Attention to modesty considerations and embellishment quality is crucial. Compliance with import regulations and halal textile certifications can be differentiators.

- Europe: Buyers expect stringent adherence to EU standards, including REACH and chemical safety regulations. Transparency in supply chain and ethical manufacturing practices are increasingly demanded.

- Emerging Sourcing Countries (Vietnam, Egypt): While cost-effective, these markets require thorough QC oversight due to variable infrastructure. Partnering with manufacturers that invest in modern equipment and skilled labor, as well as those with ISO 9001 certification, reduces risks.

Summary

For international B2B buyers sourcing empire cut wedding dresses, a clear understanding of the manufacturing and quality assurance processes enables informed decisions and long-term supplier partnerships. By focusing on detailed production stages, adhering to recognized quality standards, and implementing robust supplier verification methods, buyers can secure elegant, well-crafted dresses that meet the diverse preferences and regulatory requirements of global bridal markets.

Related Video: Complete Process of Textile Manufacturing Fiber to Complete Garments

Comprehensive Cost and Pricing Analysis for wedding dresses empire cut Sourcing

Key Cost Components in Empire Cut Wedding Dress Production

When sourcing empire cut wedding dresses, understanding the underlying cost structure is critical for effective negotiation and budgeting. The primary cost components include:

- Materials: Premium fabrics such as silk, chiffon, lace, and tulle dominate the material costs. High-quality European or imported textiles often command higher prices but ensure superior drape and finish essential for the empire silhouette.

- Labor: Skilled labor is vital, especially since over 50% of production may be hand-finished to maintain dress quality and reduce defects. Labor costs vary significantly by region, with countries like Vietnam offering competitive rates while maintaining craftsmanship.

- Manufacturing Overhead: This includes utilities, factory maintenance, and indirect costs related to production. Factories equipped with modern machinery may have higher overhead but benefit from efficiency gains.

- Tooling and Equipment: Investment in specialized sewing machines, embroidery tools, and pattern-making software supports consistent quality and design complexity.

- Quality Control (QC): Rigorous inspection processes reduce returns and maintain brand reputation. QC costs factor in both time and resources dedicated to sampling and final product checks.

- Logistics and Shipping: International freight, customs duties, and insurance add to the landed cost. For B2B buyers in Africa, South America, the Middle East, and Europe, proximity to manufacturing hubs impacts shipping time and cost.

- Supplier Margin: Manufacturers typically build in a margin to cover profit and business sustainability, influenced by order size and market demand.

Influential Pricing Factors for Empire Cut Dresses

Pricing for empire cut wedding dresses can fluctuate based on several key variables:

- Order Volume and Minimum Order Quantities (MOQ): Larger volume orders usually unlock price breaks. MOQ requirements differ by supplier and can range from dozens to hundreds of pieces.

- Customization and Design Complexity: Custom embroidery, beading, or unique fabric blends increase costs. Simpler, classic designs typically cost less and are easier to source in bulk.

- Material Quality and Certification: Certified organic or ethically sourced fabrics may carry premiums but enhance brand value in discerning markets.

- Supplier Reputation and Location: Established suppliers with certifications (e.g., ISO, WRAP) might charge more but reduce risk. Proximity to suppliers in Eastern Europe or Southeast Asia can lower freight costs.

- Incoterms and Payment Terms: FOB, CIF, or DDP terms affect who bears shipping and customs costs. Favorable payment terms (e.g., letters of credit, net 30) can improve cash flow for buyers.

- Seasonality and Market Trends: Demand spikes during wedding seasons or fashion cycles may push prices up.

Strategic Buyer Tips for International B2B Sourcing

For buyers from regions such as Africa, South America, the Middle East, and Europe, the following strategies help optimize sourcing costs and ensure quality:

- Negotiate Beyond Price: Discuss payment terms, lead times, packaging, and after-sales support. Long-term partnerships often yield better overall value than one-off discounts.

- Evaluate Total Cost of Ownership (TCO): Consider customs duties, potential delays, return logistics, and quality risk. Sometimes a slightly higher unit price with reliable delivery and quality control is more cost-effective.

- Leverage Group Buying or Consolidated Shipments: Pooling orders with other buyers or consolidating shipments can reduce freight and customs expenses.

- Verify Supplier Certifications and Compliance: Confirm adherence to international quality and labor standards to avoid reputational risks and regulatory issues in your market.

- Factor in Local Market Preferences: Adapt designs and fabric choices to regional tastes and climate, which may affect material durability and consumer satisfaction.

- Use Incoterms Wisely: For example, opting for DDP (Delivered Duty Paid) can simplify customs clearance but may increase upfront costs. Assess which terms align with your logistics capabilities.

- Request Samples and Conduct Pilot Orders: Before committing to large orders, validate quality, fit, and fabric performance through samples or small batch purchases.

Indicative Pricing Disclaimer

Pricing for empire cut wedding dresses varies widely based on fabric choice, design intricacy, order volume, and supplier location. Indicative wholesale prices can range from $50 to $250 USD per unit depending on these factors. Buyers should obtain detailed quotations and factor in all ancillary costs before finalizing procurement decisions.

By thoroughly analyzing cost drivers and strategically managing supplier relationships, international B2B buyers can secure high-quality empire cut wedding dresses at competitive prices, tailored to the specific needs of their markets.

Spotlight on Potential wedding dresses empire cut Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘wedding dresses empire cut’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for wedding dresses empire cut

Critical Technical Properties for Empire Cut Wedding Dresses

1. Fabric Quality and Composition

The choice of fabric is paramount in empire cut wedding dresses. Common materials include silk, chiffon, satin, and lace blends, often sourced from European mills to meet high-quality standards. For B2B buyers, understanding fabric composition (e.g., 100% silk vs. silk blends) affects durability, drape, and comfort. Premium fabrics ensure the dress maintains its elegant silhouette and softness, which are critical for customer satisfaction and brand reputation.

2. Waistline Placement and Precision

The defining feature of an empire cut dress is its high waistline that sits just below the bust. Precision in the waistline placement is essential to achieve the characteristic elongating effect and flattering fit. Manufacturers must adhere to strict tolerances (±0.5 cm) to ensure consistency across production batches, which is crucial for maintaining design integrity and minimizing returns.

3. Skirt Construction and Flow

Empire cut dresses feature a gathered or loosely fitted skirt that flows from the high waistline. The skirt’s cut and volume must balance elegance with wearability, often requiring careful pattern grading for different sizes. The fabric’s weight and finishing techniques (e.g., lining, hemming) influence the skirt’s movement and silhouette, impacting the dress’s appeal in diverse climates and markets such as Africa and the Middle East.

4. Embellishment and Accessory Integration

Many empire cut wedding dresses incorporate embellishments like lace appliqués, beadwork, or embroidery around the bodice or neckline. From a B2B perspective, understanding the sourcing and application methods (hand-sewn vs. machine-embellished) is vital. Embellishment quality affects production time, cost, and final retail price, influencing order quantities and pricing strategies.

5. Size Grading and Fit Standards

Given the international clientele, especially from regions with varying body types (e.g., Europe vs. South America), accurate size grading is critical. Suppliers should provide detailed size charts aligned with regional standards and offer customization options. Proper fit reduces alterations and returns, improving operational efficiency for retailers and distributors.

6. Production Tolerances and Quality Control

Consistent quality control measures, including tolerance checks on seams, stitching, and fabric defects, are essential to meet buyer expectations. For empire cut dresses, where silhouette precision is key, a maximum defect rate of 1-2% is often acceptable. Reliable quality control reduces costly rejections and builds trust with international B2B partners.

Common Industry and Trade Terminology

OEM (Original Equipment Manufacturer)

This term refers to manufacturers that produce wedding dresses based on a buyer’s designs or specifications. Many B2B buyers prefer OEM services to offer exclusive collections under their brand name, ensuring product differentiation and brand control.

MOQ (Minimum Order Quantity)

MOQ defines the smallest number of units a manufacturer will produce per order. For empire cut wedding dresses, MOQs can vary widely depending on fabric sourcing and embellishment complexity. Buyers should negotiate MOQs that align with their inventory capacity and market demand, especially when entering new regions.

RFQ (Request for Quotation)

An RFQ is a formal inquiry sent by buyers to suppliers requesting price and production details for specific dress models. Clear RFQs including technical specs, quantities, and delivery timelines streamline the procurement process and reduce misunderstandings.

Incoterms (International Commercial Terms)

Incoterms such as FOB (Free On Board), CIF (Cost, Insurance, and Freight), and DDP (Delivered Duty Paid) define the responsibilities and risks between buyers and sellers during shipping. Understanding these terms helps buyers from Africa, South America, and the Middle East plan logistics and cost management effectively.

Lead Time

Lead time refers to the period from order confirmation to product delivery. For empire cut dresses, lead times typically range from 45 to 90 days depending on customization and order size. Accurate lead time forecasts enable buyers to manage inventory and promotional activities efficiently.

Bulk Fabric Consumption

This term relates to the amount of fabric required per dress, influencing cost and inventory planning. Empire cut dresses generally require more fabric due to their flowing skirts. Buyers should request detailed fabric consumption data to optimize order quantities and reduce waste.

Understanding these technical properties and trade terms equips international B2B buyers with the knowledge to make informed decisions, negotiate effectively, and build successful partnerships in the empire cut wedding dress market.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the wedding dresses empire cut Sector

Market Overview & Key Trends

The global wedding dress market, particularly for empire cut styles, is experiencing steady growth driven by a rising demand for timeless elegance and versatility in bridal wear. This silhouette’s flattering high-waist design appeals widely across diverse markets, including Africa, South America, the Middle East, and Europe, where cultural preferences favor modest yet sophisticated bridal fashion. For international B2B buyers, understanding regional nuances is crucial: for instance, Middle Eastern markets often prioritize luxurious fabrics and intricate embellishments, while African and South American buyers may seek vibrant colors and adaptable designs suitable for diverse climates.

Current sourcing trends emphasize agility and customization. Buyers are increasingly partnering with manufacturers who offer flexible production runs that accommodate seasonal shifts and localized tastes. Digital platforms have become essential for streamlined communication, virtual sampling, and order tracking, enabling buyers from countries like Egypt and Vietnam to efficiently connect with European and CIS manufacturers known for high-quality materials and craftsmanship.

Technology adoption, including 3D design software and automated cutting machines, is enhancing production precision and reducing lead times. These innovations allow suppliers to cater to bespoke demands typical for empire cut wedding dresses, where fabric drape and silhouette integrity are paramount. Moreover, competitive pricing remains a key factor, with manufacturers such as EmaBride offering high-quality European fabrics combined with cost-effective labor to serve emerging markets.

In summary, successful B2B engagement in the empire cut wedding dress segment requires buyers to leverage technological advancements, understand cultural preferences, and prioritize partnerships with manufacturers who balance quality, flexibility, and competitive pricing.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a decisive factor for international buyers sourcing empire cut wedding dresses, reflecting growing consumer awareness and regulatory pressures worldwide. The environmental impact of bridal fashion is significant due to intensive fabric use—often silk, satin, or lace—and the energy consumed in production. B2B buyers should prioritize suppliers committed to minimizing waste through optimized cutting techniques and employing natural, biodegradable fibers.

Ethical sourcing goes beyond environmental concerns, encompassing fair labor practices and transparent supply chains. Buyers from regions such as Europe and the Middle East increasingly demand certifications like GOTS (Global Organic Textile Standard), OEKO-TEX, and Fair Trade to ensure products meet high social and environmental standards. Partnering with manufacturers who provide full traceability from raw materials to finished garments enhances brand reputation and aligns with international compliance frameworks.

In the empire cut sector, sustainable innovations include using organic cotton blends, recycled polyester, and eco-friendly dyes that reduce chemical runoff. Additionally, manufacturers integrating handcrafted elements with mechanized production often achieve a balance between quality and lower carbon footprints. B2B buyers can also explore circular economy models, such as rental or resale partnerships, to address post-wedding garment lifecycle concerns.

By embedding sustainability into sourcing strategies, international buyers not only meet evolving market expectations but also future-proof their supply chains against tightening environmental regulations and shifting consumer values.

Brief Evolution and Historical Context

The empire cut silhouette traces its roots to the late 18th and early 19th centuries during the Regency era, inspired by classical Greco-Roman tunics. Its hallmark is a high waistline positioned just below the bust, creating a flowing, elongated skirt that flatters various body types. This style gained renewed popularity in the 1960s and has since become a staple in bridal fashion for its romantic and versatile appeal.

For B2B buyers, this historical lineage underscores the enduring demand for empire cut dresses as a classic yet adaptable bridal option. Understanding this heritage helps in marketing collections that appeal to brides seeking both tradition and modern elegance. Moreover, the silhouette’s simplicity allows for diverse fabric and embellishment choices, enabling manufacturers to innovate while respecting timeless design principles.

This comprehensive insight equips B2B buyers to navigate the empire cut wedding dress market effectively, balancing market dynamics, sourcing innovations, and sustainability imperatives to maximize value and responsiveness in global bridal fashion supply chains.

Related Video: International Trade 101 | Economics Explained

Frequently Asked Questions (FAQs) for B2B Buyers of wedding dresses empire cut

-

How can I effectively vet suppliers of empire cut wedding dresses to ensure product quality and reliability?

Start by requesting detailed product samples and certifications related to fabric quality and manufacturing standards. Verify the supplier’s reputation through client testimonials and independent third-party audits. For regions like Europe and the Middle East, prioritize suppliers who comply with international textile standards (e.g., OEKO-TEX, ISO). Additionally, assess their production capacity and responsiveness to communication. Visiting the supplier’s factory or hiring a local quality inspection service can provide deeper insights into their operational capabilities and adherence to quality controls. -

Is customization available for empire cut wedding dresses, and how should I approach it in negotiations?

Most reputable manufacturers offer customization in fabric, embroidery, embellishments, and sizing to cater to diverse markets such as Africa and South America. When negotiating, clearly specify your target market’s preferences and regulatory requirements (e.g., modesty norms in the Middle East). Request a tech pack or detailed design sheets to ensure mutual understanding. Be prepared for minimum order quantities (MOQs) that may vary with customization complexity and discuss lead times upfront, as bespoke options often extend production schedules. -

What are typical minimum order quantities (MOQs) and lead times for wholesale empire cut wedding dresses?

MOQs can range from 30 to 100 units per design, depending on the supplier’s scale and customization level. Lead times typically span 45 to 90 days, factoring in fabric sourcing, production, and quality checks. For buyers in regions like Vietnam or Egypt, consider potential delays due to customs clearance and regional holidays. Establish clear timelines in contracts and maintain regular communication with suppliers to manage expectations and mitigate risks of late deliveries. -

Which payment terms are common in international B2B transactions for empire cut wedding dresses?

Suppliers often require a 30-50% upfront deposit with the balance paid before shipment or upon delivery. Letters of credit (LC) and escrow services are advisable for larger orders to protect both parties. For buyers in emerging markets, negotiating flexible payment schedules based on order history can build trust. Always confirm payment methods accepted (e.g., wire transfer, PayPal, Alibaba Trade Assurance) and be mindful of currency exchange fees and banking regulations in your country. -

What quality assurance (QA) measures should I insist on when sourcing empire cut wedding dresses?

Request detailed QA protocols including fabric inspection, stitching quality, embellishment durability, and sizing accuracy. Insist on in-line and final random inspections, ideally conducted by third-party agencies familiar with international standards. Certifications such as ISO 9001 or compliance with REACH (for chemical safety) can be strong quality indicators. For sensitive markets, demand photo or video reports during production milestones to catch defects early and avoid costly returns. -

How can I optimize logistics and shipping for bulk orders of empire cut wedding dresses?

Coordinate with suppliers to consolidate shipments to reduce freight costs, especially for distant markets like South America and Africa. Choose reliable freight forwarders experienced in handling textiles and customs clearance in your target region. Consider shipping methods balancing cost and speed—sea freight for bulk orders or air freight for urgent replenishments. Negotiate Incoterms clearly (e.g., FOB, CIF) to define responsibility for shipping, insurance, and duties, minimizing disputes upon arrival.

Illustrative Image (Source: Google Search)

-

What certifications or compliance standards should I check for empire cut wedding dress suppliers?

Look for certifications ensuring ethical manufacturing and product safety such as OEKO-TEX Standard 100 (to certify textiles free from harmful substances), ISO 9001 (quality management), and WRAP (Worldwide Responsible Accredited Production) for social compliance. Depending on your market, verify compliance with local import regulations, including flammability standards and labeling requirements. These certifications not only guarantee quality but also enhance your brand’s credibility in international markets. -

How should I handle disputes or quality issues with international suppliers of wedding dresses?

Establish clear dispute resolution clauses in your purchase agreement, specifying mediation or arbitration venues. Maintain comprehensive documentation including contracts, emails, and inspection reports. Promptly communicate issues with supporting evidence and seek amicable solutions such as partial refunds, replacement shipments, or discounts. For persistent problems, engage trade associations or use platforms with buyer protection mechanisms. Building long-term partnerships with transparent communication reduces the likelihood of disputes.

Strategic Sourcing Conclusion and Outlook for wedding dresses empire cut

The empire cut wedding dress remains a timeless and versatile choice for brides worldwide, making it a strategic product category for international B2B buyers. Its flattering silhouette appeals to diverse body types, while the classic yet adaptable design aligns well with evolving fashion trends. For buyers in Africa, South America, the Middle East, and Europe, sourcing empire cut dresses offers a competitive advantage by meeting the demand for elegant, culturally adaptable bridal wear.

Key sourcing insights include:

- Supplier Selection: Prioritize manufacturers with proven expertise in quality craftsmanship and access to premium European fabrics, ensuring dresses meet international standards.

- Customization and Trends: Engage suppliers capable of flexible design adaptations to cater to regional preferences and seasonal fashion shifts.

- Cost Efficiency: Leverage direct wholesale partnerships to balance superior quality with competitive pricing, vital for emerging bridal markets.

- Logistics and Support: Focus on suppliers offering reliable delivery and responsive customer service to streamline supply chain operations across continents.

Looking ahead, the empire cut wedding dress market is poised for growth fueled by increasing bridal demand and global fashion influences. B2B buyers who adopt a strategic sourcing approach—emphasizing quality, adaptability, and supplier collaboration—will unlock new revenue streams and strengthen their market positioning. Now is the opportune moment to deepen partnerships with reputable manufacturers and expand your bridal portfolio to capture this enduring trend.