Your Ultimate Guide to Sourcing Cleaners That Clean Wedding

Guide to Cleaners That Clean Wedding Dresses

- Introduction: Navigating the Global Market for cleaners that clean wedding dresses

- Understanding cleaners that clean wedding dresses Types and Variations

- Key Industrial Applications of cleaners that clean wedding dresses

- Strategic Material Selection Guide for cleaners that clean wedding dresses

- In-depth Look: Manufacturing Processes and Quality Assurance for cleaners that clean wedding dresses

- Comprehensive Cost and Pricing Analysis for cleaners that clean wedding dresses Sourcing

- Spotlight on Potential cleaners that clean wedding dresses Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for cleaners that clean wedding dresses

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the cleaners that clean wedding dresses Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of cleaners that clean wedding dresses

- Strategic Sourcing Conclusion and Outlook for cleaners that clean wedding dresses

Introduction: Navigating the Global Market for cleaners that clean wedding dresses

The global market for cleaners that specialize in wedding dress care represents a unique and growing niche within the textile and garment maintenance industry. For international B2B buyers, particularly those operating in Africa, South America, the Middle East, and Europe, sourcing reliable and expert cleaning solutions for wedding dresses is critical. Wedding gowns are delicate, often crafted from intricate fabrics and adorned with embellishments that require specialized cleaning techniques to preserve their beauty and value over time.

Understanding the complexities of wedding dress cleaners—from the variety of cleaning types and fabric compatibility to manufacturing standards and quality control—is essential for making informed procurement decisions. This guide offers a comprehensive exploration of the sector, covering key aspects such as:

- Types of cleaners: including wet cleaning, dry cleaning, and preservation services tailored to bridal wear.

- Materials and fabric care: insights on handling silks, lace, beading, and other delicate textiles.

- Manufacturing and quality assurance: evaluating supplier capabilities and certification standards.

- Supplier landscape and sourcing strategies: identifying trusted global and regional providers.

- Cost structures and market trends: understanding pricing models and demand drivers.

- Frequently asked questions: addressing common buyer concerns and operational challenges.

Equipped with this knowledge, B2B buyers can confidently navigate supplier negotiations, ensure compliance with quality expectations, and ultimately deliver exceptional value to end customers. Whether you are a retailer, wedding service provider, or textile care specialist in emerging or established markets, this guide empowers you to optimize your sourcing approach for wedding dress cleaning solutions worldwide.

Understanding cleaners that clean wedding dresses Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Specialist Dry Cleaners | Use of gentle, non-water solvents tailored for delicate fabrics | High-end bridal boutiques, wedding dress preservation firms | Pros: Preserves delicate fabrics and embellishments; Cons: Higher cost, longer turnaround |

| Wet Cleaning Experts | Professional water-based cleaning with specialized detergents | Bridal shops, luxury dry cleaners | Pros: Eco-friendly, effective on organic stains; Cons: Risk of fabric shrinkage or damage if not expertly handled |

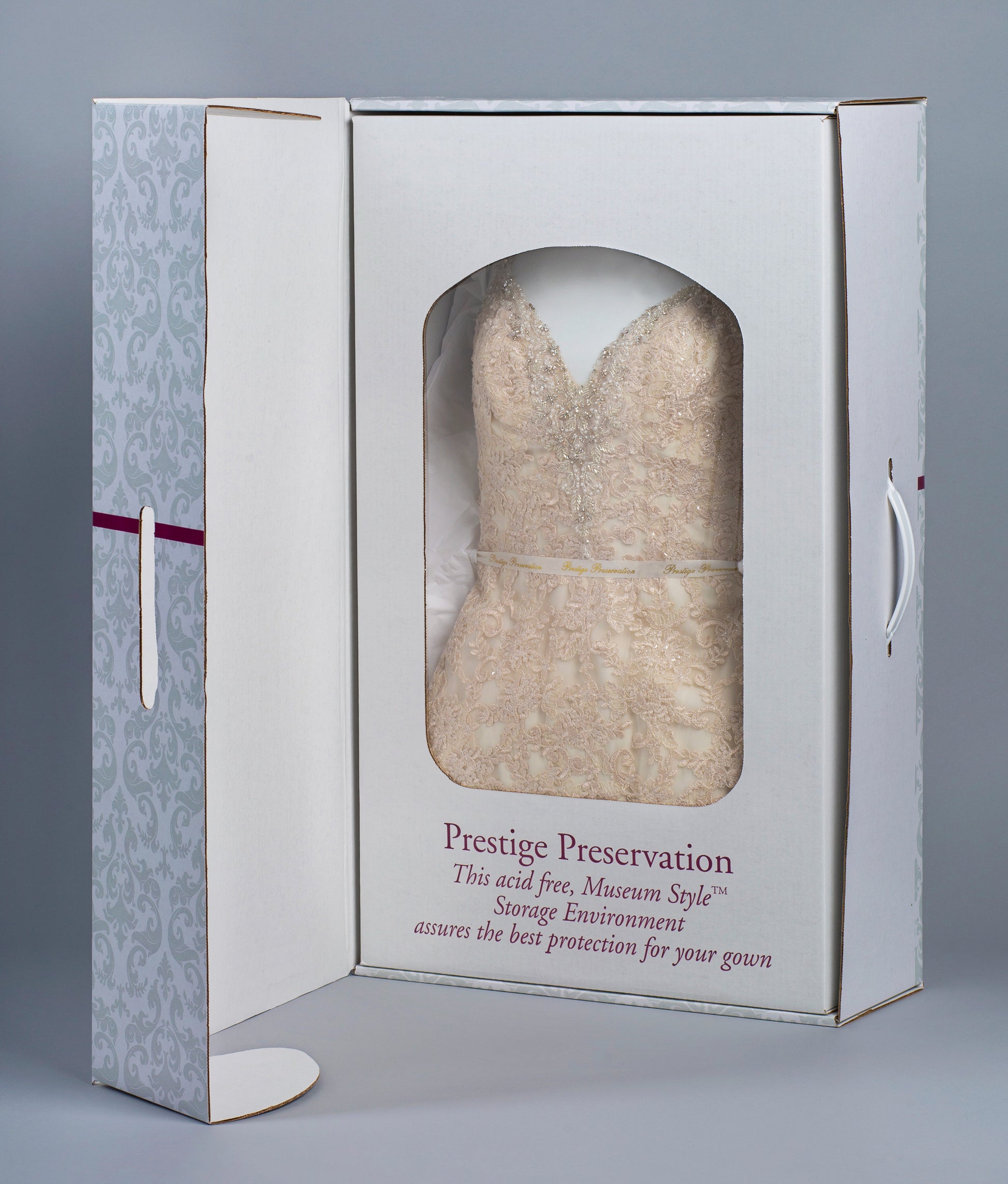

| Preservation and Packaging Services | Combined cleaning and archival-quality packaging for long-term storage | Preservation specialists, online bridal preservation services | Pros: Extends dress lifespan, adds value with presentation; Cons: Requires expertise, premium pricing |

| Multi-Service Cleaners | Offer cleaning plus repairs, alterations, and accessory care | Full-service bridal care providers, department stores | Pros: One-stop solution, convenience; Cons: Variable quality across services, may lack specialization |

| Mobile/Remote Cleaning Kits | Kits shipped to clients for dress collection and return after cleaning | International buyers, remote bridal shops | Pros: Enables global reach, convenient logistics; Cons: Risk of damage during shipping, reliance on courier services |

Specialist Dry Cleaners

These cleaners utilize advanced solvent-based methods designed specifically for wedding dresses made from silks, satins, and delicate lace. Their expertise lies in removing tough stains without compromising beadwork or sequins. For B2B buyers, especially bridal boutiques and preservation businesses, selecting such specialists ensures premium service quality, justifying higher price points. Key considerations include verifying certifications and turnaround times to meet client expectations.

Wet Cleaning Experts

Wet cleaning is a professional, eco-conscious alternative that employs water and specialized detergents to gently cleanse wedding gowns. This method suits organic stains like sweat or wine but demands expert handling to avoid fabric distortion. B2B buyers targeting environmentally aware markets in Europe or the Middle East may find wet cleaning appealing. Assessing the cleaner’s technical skill and fabric compatibility is critical to avoid costly damage.

Preservation and Packaging Services

These providers combine meticulous cleaning with archival-grade packaging solutions, such as acid-free boxes and tissue paper, to protect dresses for decades. This integrated service is highly valued by preservation specialists and online bridal services catering to global clients. B2B buyers should evaluate the quality of preservation materials and warranty policies, as these factors influence customer satisfaction and repeat business.

Multi-Service Cleaners

Offering a comprehensive suite including cleaning, repairs, and accessory care, multi-service cleaners appeal to bridal retailers seeking convenience and a single point of contact. While this can streamline operations, buyers must carefully vet service quality to ensure each aspect meets the high standards wedding dresses demand. This option suits department stores and large bridal chains looking for scalable solutions.

Mobile/Remote Cleaning Kits

These kits facilitate remote cleaning by providing customers with packaging materials to send dresses to centralized cleaning facilities. This model is especially advantageous for international B2B buyers in Africa, South America, or the Middle East, where local expertise may be limited. Buyers should consider logistics reliability, insurance for transit damage, and the reputation of the cleaning partner to mitigate risks inherent in shipping valuable garments.

Related Video: Large Language Models (LLMs) – Everything You NEED To Know

Key Industrial Applications of cleaners that clean wedding dresses

| Industry/Sector | Specific Application of cleaners that clean wedding dresses | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Bridal Boutiques & Retail | On-site cleaning and preservation services for wedding gowns and accessories | Enhances customer satisfaction and loyalty through premium care | Effectiveness on delicate fabrics, eco-friendliness, ease of use |

| Dry Cleaning & Laundry | Specialized cleaning of wedding dresses with delicate fabrics and embellishments | Expands service portfolio and attracts high-value clientele | Compatibility with various textiles, stain removal efficiency, safety |

| Wedding Dress Preservation Services | Long-term preservation cleaning to prevent yellowing and fabric degradation | Adds value through lifetime preservation guarantees | Proven preservation methods, packaging compatibility, warranty terms |

| Textile Restoration Labs | Restoration and cleaning of vintage or damaged wedding dresses | Enables restoration of high-value garments for resale or display | Gentle cleaning agents, preservation of fabric integrity, expertise |

| Event Rental Services | Cleaning and maintenance of rented wedding dresses and accessories | Maintains garment quality for repeat rentals, reduces replacement costs | Durability of cleaning agents, fast turnaround, cost-effectiveness |

Bridal Boutiques & Retail

Bridal boutiques and retail outlets use specialized cleaners to offer on-site cleaning and preservation services for wedding gowns and accessories. This service differentiates their brand by providing a premium experience that enhances customer satisfaction and loyalty. For international buyers in regions like Africa and South America, sourcing cleaners that are effective on delicate fabrics and environmentally friendly is critical. These cleaners must also be easy to use by boutique staff with varying levels of technical expertise.

Dry Cleaning & Laundry Services

Professional dry cleaners and laundry businesses incorporate specialized cleaners designed for wedding dresses, which often feature delicate fabrics, lace, and intricate beading. These cleaners enable service providers to expand their portfolio to include high-value bridal garments, attracting upscale clientele. For B2B buyers in the Middle East and Europe, it is essential to select products that ensure thorough stain removal without damaging sensitive textiles, and that comply with local environmental regulations.

Wedding Dress Preservation Services

Companies focusing on wedding dress preservation use cleaners that not only remove stains but also inhibit yellowing and fabric degradation over time. This is especially important for clients looking to preserve garments as heirlooms. International buyers should prioritize cleaners backed by proven preservation methods and those that come with clear warranty and packaging solutions, ensuring the dress remains in pristine condition during long-term storage.

Textile Restoration Labs

Specialized textile restoration laboratories utilize cleaners capable of gently restoring vintage or damaged wedding dresses, often required for resale or museum display. These cleaners must maintain fabric integrity while effectively removing stains and discolorations. Buyers in Europe and South Africa often seek products with advanced formulations that support expert restoration work without compromising delicate embroidery or fabric strength.

Event Rental Services

Businesses offering wedding dress rentals require cleaners that can quickly and effectively clean and maintain dresses and accessories between rentals. The cleaners must be durable enough to handle repeated use yet gentle to preserve garment quality. For B2B buyers in fast-growing markets like Kenya and the Middle East, sourcing cost-effective cleaning solutions that enable fast turnaround times is key to maintaining profitability and customer satisfaction.

Related Video: 16 Uses for WD-40 Everyone Should Know

Strategic Material Selection Guide for cleaners that clean wedding dresses

Common Materials Used in Equipment for Cleaning Wedding Dresses: A B2B Perspective

When selecting materials for manufacturing or sourcing cleaners that clean wedding dresses, it is crucial to consider the delicate nature of the garments and the cleaning processes involved. Wedding dresses often contain fragile fabrics such as silk, lace, satin, and tulle, which require gentle handling and precise cleaning conditions. Below is an analysis of four commonly used materials in the manufacturing of cleaning equipment and components, focusing on their suitability for this specialized application.

1. Stainless Steel (Typically 304 or 316 Grades)

Key Properties:

Stainless steel is renowned for its excellent corrosion resistance, especially grades 316 which offer superior resistance to chlorides and other cleaning agents. It withstands moderate to high temperatures (up to 870°C for 304 and slightly higher for 316) and maintains mechanical strength under pressure, making it ideal for cleaning machinery parts exposed to steam or chemical solvents.

Pros:

– High corrosion resistance ensures longevity even with frequent exposure to moisture and detergents.

– Non-reactive surface prevents contamination or staining of delicate fabrics.

– Easy to clean and sterilize, supporting hygiene standards.

– Durable and resistant to wear and tear.

Cons:

– Higher cost compared to carbon steel or plastics.

– Heavier, potentially increasing equipment weight and transport costs.

– Manufacturing complexity can increase lead times.

Impact on Application:

Stainless steel components are ideal for parts in direct contact with cleaning solvents and water, such as tanks, nozzles, and piping. They ensure no chemical interaction that could damage the wedding dress fabrics or leave residues.

Considerations for International Buyers:

Buyers from Africa, South America, the Middle East, and Europe should verify compliance with international standards like ASTM A240 (for stainless steel sheets) or EN 10088 (European standard). In regions with high humidity or saline environments (e.g., coastal Kenya or South Africa), grade 316 is preferred for enhanced corrosion resistance. Cost sensitivity in emerging markets may require balancing grade selection with budget constraints.

2. High-Density Polyethylene (HDPE)

Key Properties:

HDPE is a thermoplastic known for its chemical resistance, low moisture absorption, and impact resistance. It can operate effectively in temperatures up to 120°C, making it suitable for certain cleaning process components.

Pros:

– Excellent resistance to many detergents and mild solvents used in wedding dress cleaning.

– Lightweight and easy to fabricate into various shapes.

– Cost-effective compared to metals.

– Non-abrasive, reducing risk of mechanical damage to delicate fabrics.

Cons:

– Lower mechanical strength limits use in high-pressure or high-temperature applications.

– Susceptible to deformation under prolonged heat exposure.

– Can be prone to scratching, which may harbor contaminants.

Impact on Application:

HDPE is ideal for external housings, detergent reservoirs, and non-critical piping where chemical resistance is essential but mechanical loads are low. It reduces overall equipment weight and cost.

Considerations for International Buyers:

Compliance with FDA or EU food-grade standards may be necessary if the cleaning process involves contact with skin-sensitive fabrics. In regions with high ambient temperatures (e.g., Middle East), buyers should ensure HDPE components are rated for local conditions to avoid warping. Availability and cost of HDPE can vary, so sourcing from reputable suppliers is advised.

3. Aluminum Alloys (e.g., 6061 or 5052)

Key Properties:

Aluminum alloys offer a good balance of strength, corrosion resistance, and light weight. They perform well at moderate temperatures and resist oxidation, especially when anodized.

Pros:

– Lightweight, reducing equipment transport and handling costs.

– Good corrosion resistance, especially with protective coatings.

– Excellent thermal conductivity, useful in heating elements or temperature regulation.

– Easier and less costly to machine than stainless steel.

Cons:

– Less corrosion-resistant than stainless steel, especially in harsh chemical environments.

– Can react with alkaline cleaning agents, potentially causing pitting or discoloration.

– Surface scratches can compromise protective oxide layer.

Impact on Application:

Aluminum is suitable for structural frames, heat exchangers, or components not in direct contact with aggressive cleaning chemicals. Its thermal properties can improve energy efficiency in cleaning cycles.

Considerations for International Buyers:

Buyers in humid or coastal regions should consider anodized or coated aluminum to extend service life. Standards such as ASTM B209 (for aluminum sheets) or EN 573 (European standard) should be referenced. Aluminum’s moderate cost and weight advantages make it attractive for markets with logistical challenges.

4. Silicone Rubber (for Seals and Gaskets)

Key Properties:

Silicone rubber is highly flexible, chemically inert, and stable across a wide temperature range (-60°C to 230°C). It resists degradation from detergents, steam, and mild solvents.

Pros:

– Excellent sealing properties prevent leaks and contamination.

– Maintains elasticity and integrity over repeated cleaning cycles.

– Non-toxic and hypoallergenic, safe for delicate fabrics.

– Resistant to UV and ozone, extending lifespan.

Cons:

– Higher material cost compared to standard rubber.

– Limited mechanical strength; not suitable for load-bearing parts.

– Can be damaged by strong acids or bases.

Impact on Application:

Essential for gaskets, seals, and flexible connectors in cleaning machines to ensure airtight and watertight operation without fabric damage.

Considerations for International Buyers:

Ensure compliance with international standards such as ASTM D2000 for rubber materials. In hot climates (Middle East, parts of Africa), silicone’s thermal stability is a significant advantage. Buyers should verify supplier certifications to guarantee material purity and performance.

Summary Table of Material Selection for Cleaners That Clean Wedding Dresses

| Material | Typical Use Case for cleaners that clean wedding dresses | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel (304/316) | Tanks, piping, nozzles, and parts exposed to water and solvents | Superior corrosion resistance and durability | Higher cost and heavier than alternatives | High |

| High-Density Polyethylene (HDPE) | Detergent reservoirs, housings, and low-pressure piping | Chemical resistance and lightweight | Limited mechanical strength and heat tolerance | Low |

| Aluminum Alloys (6061/5052) | Structural frames, heat exchangers, and components with thermal roles | Lightweight with good thermal conductivity | Less corrosion resistance; reactive |

In-depth Look: Manufacturing Processes and Quality Assurance for cleaners that clean wedding dresses

When sourcing professional cleaners that specialize in wedding dress care, understanding the manufacturing processes behind the cleaning products and equipment—as well as the rigorous quality assurance (QA) protocols—is essential for international B2B buyers. This knowledge enables buyers from Africa, South America, the Middle East, and Europe to select reliable suppliers who meet global standards and local market expectations.

Manufacturing Processes for Wedding Dress Cleaning Solutions and Equipment

The manufacturing of cleaners specifically designed for wedding dress cleaning typically involves multiple critical stages to ensure efficacy, safety, and fabric compatibility. These products may include specialized detergents, stain removers, preservation chemicals, and cleaning machinery or tools.

1. Material Preparation

- Raw Material Selection: High-purity surfactants, enzymes, solvents, and fabric-safe chemicals are sourced with strict specifications to avoid damage to delicate fabrics like silk, lace, and tulle.

- Pre-Processing: Ingredients undergo filtration, purification, and quality checks to ensure absence of contaminants that could discolor or weaken wedding dress materials.

- Compatibility Testing: Materials are tested for pH balance and chemical stability to ensure gentle yet effective cleaning action.

2. Formulation and Mixing

- Precision Blending: Active ingredients are mixed under controlled temperature and agitation to achieve uniformity and optimal cleaning performance.

- Batch Consistency: Automated dosing systems ensure each batch matches the exact formula, critical for repeatable quality.

- Additive Incorporation: Stabilizers, fragrances, and preservatives are added in measured amounts to enhance shelf life without affecting fabric safety.

3. Filling and Packaging

- Sanitized Filling Lines: Cleaners are dispensed into sterilized containers—bottles, spray cans, or pouches—using automated filling machines to prevent contamination.

- Labeling and Sealing: Packaging includes clear instructions, safety data, and certifications. Seals ensure product integrity during transport.

- Sustainability Considerations: Many manufacturers incorporate recyclable or biodegradable packaging materials, an increasingly important factor for environmentally conscious buyers.

4. Equipment Assembly (For Cleaning Machines)

- Component Sourcing: Durable materials such as stainless steel, corrosion-resistant plastics, and precision electronics are selected.

- Modular Assembly: Machines are assembled in stages—frame construction, motor installation, control system integration, and final calibration.

- Performance Tuning: Functional testing ensures machines operate silently, efficiently, and safely, with settings customized for delicate wedding dress fabrics.

Quality Assurance Frameworks and Checkpoints

Robust QA processes underpin the reliability of cleaners and equipment. International B2B buyers should expect suppliers to adhere to recognized quality standards and provide transparent quality documentation.

Relevant International Standards

- ISO 9001: The global benchmark for quality management systems, ISO 9001 certification indicates a supplier’s commitment to consistent product quality, continuous improvement, and customer satisfaction.

- REACH Compliance (EU): Ensures chemicals used do not pose risks to human health or the environment, critical for buyers in Europe.

- CE Marking (Europe): For cleaning machines, CE marking certifies conformity with EU safety, health, and environmental protection requirements.

- EPA Registration (US/International): Some cleaning chemicals may require EPA approval for safety and environmental compliance.

- OHSAS 18001 / ISO 45001: Occupational health and safety management standards, relevant for manufacturing facilities ensuring safe production environments.

Quality Control Checkpoints

- Incoming Quality Control (IQC): Raw materials and components are inspected for purity, compliance certificates, and physical properties before use.

- In-Process Quality Control (IPQC): Continuous monitoring during formulation and assembly phases, including viscosity checks for liquids, mechanical testing for equipment parts, and contamination control.

- Final Quality Control (FQC): Finished products undergo comprehensive testing such as chemical composition analysis, microbial testing for detergents, and operational testing for machines.

- Packaging Inspection: Ensures labeling accuracy, seal integrity, and packaging durability.

Common Testing Methods

- Spectroscopic Analysis: Verifies chemical composition and detects impurities.

- pH and Viscosity Testing: Ensures cleaning solutions are within safe parameters for delicate fabrics.

- Microbial Contamination Tests: Critical for aqueous products to prevent mold or bacterial growth.

- Mechanical and Electrical Safety Tests: For cleaning equipment, includes load testing, insulation resistance, and user safety features.

- Performance Trials: Simulated cleaning tests on fabric swatches to confirm stain removal efficacy without damage.

Verifying Supplier Quality Assurance for B2B Buyers

International buyers face challenges verifying quality remotely. Effective supplier evaluation includes:

- Factory Audits: Conduct on-site or third-party audits assessing manufacturing processes, hygiene, equipment maintenance, employee training, and QA documentation.

- Review of Quality Certificates: Obtain copies of ISO 9001, CE, REACH, or other relevant certificates with validity checks.

- Sample Testing: Request product samples for independent laboratory testing to verify claims and compatibility with local fabric types.

- Production and QC Reports: Insist on batch production records, raw material certificates of analysis (CoA), and inspection reports.

- Third-Party Inspections: Engage inspection agencies to perform pre-shipment inspections, ensuring compliance with specifications and international standards.

- Supplier Transparency: Choose suppliers offering full traceability of raw materials and open communication channels.

Quality Assurance Nuances for Buyers in Africa, South America, the Middle East, and Europe

- Regulatory Variations: Buyers should be aware of differing import regulations and chemical safety standards. For example, South African buyers must comply with SANS standards, while European buyers adhere to stringent REACH and CE regulations.

- Climate Considerations: High humidity and temperature variations in regions like the Middle East and parts of Africa may affect storage and shelf life; therefore, QA must include stability testing under varied environmental conditions.

- Cultural and Market Preferences: Some markets prioritize eco-friendly and hypoallergenic products, influencing formulation and packaging requirements.

- Logistical Challenges: Extended shipping times and customs inspections require robust packaging and documentation to preserve product integrity.

- After-Sales Support: Buyers should prioritize suppliers with strong global support networks, including local representatives or authorized service centers for equipment maintenance.

Summary for B2B Buyers

For international buyers sourcing cleaners for wedding dress care, partnering with manufacturers who implement meticulous production processes and comprehensive quality assurance systems is paramount. Assessing suppliers based on their adherence to international standards, transparency in QC documentation, and ability to customize solutions for regional needs will ensure procurement of high-quality, reliable products that safeguard the delicate nature of wedding dresses.

By conducting thorough supplier audits, demanding certification evidence, and leveraging third-party inspections, buyers in Africa, South America, the Middle East, and Europe can confidently select partners capable of delivering products that meet both global benchmarks and local market expectations.

Related Video: Amazing Garment Manufacturing Process from Fabric to Finished Product Inside the Factory

Comprehensive Cost and Pricing Analysis for cleaners that clean wedding dresses Sourcing

Breakdown of Cost Components in Wedding Dress Cleaning Services

Understanding the underlying cost structure is essential for B2B buyers sourcing cleaners that specialize in wedding dress cleaning. The key cost components typically include:

- Materials: Specialized cleaning solvents, stain removers, preservation chemicals, and packaging materials such as acid-free boxes and tissue paper. High-quality, fabric-safe materials are critical to avoid damage.

- Labor: Skilled labor is a major cost driver, as wedding dress cleaning demands expert handling, detailed inspection, and hand-finishing. Labor costs vary significantly by region and expertise level.

- Manufacturing Overhead: This includes facility costs, utilities, equipment depreciation, and administrative expenses associated with the cleaning process.

- Tooling and Equipment: Investment in advanced dry-cleaning machines, spotting tools, pressing equipment, and preservation sealing apparatus.

- Quality Control (QC): Rigorous inspection stages to ensure stain removal, fabric integrity, and correct packaging. QC often involves additional labor and time.

- Logistics: Costs of inbound and outbound shipping, especially for international buyers. Packaging must ensure safe transit to prevent damage.

- Margin: Cleaners incorporate profit margins that reflect brand reputation, service quality, and market positioning.

Pricing Influencers in Wedding Dress Cleaning

Several factors influence the final price offered by cleaning service providers:

- Order Volume and Minimum Order Quantities (MOQ): Bulk or repeat orders can attract discounts. However, many wedding dress cleaners operate on a per-piece basis due to the bespoke nature of the service.

- Specifications and Customization: Dresses with delicate fabrics like silk or intricate embellishments such as beads and crystals require more labor-intensive cleaning and preservation, increasing costs.

- Materials Used: Premium preservation materials and packaging solutions add to pricing.

- Quality Certifications and Service Guarantees: Cleaners with certifications (e.g., ISO quality standards) or lifetime warranties typically command higher prices but offer added assurance.

- Supplier Location and Infrastructure: Proximity to major logistics hubs, availability of specialized labor, and technological capabilities impact cost competitiveness.

- Incoterms and Shipping Terms: For international buyers, understanding Incoterms (FOB, CIF, DDP, etc.) is vital. Shipping terms affect responsibility and cost allocation for logistics, customs duties, and insurance.

Strategic Tips for International B2B Buyers

For buyers from Africa, South America, the Middle East, and Europe, such as Kenya or South Africa, navigating the pricing landscape requires strategic consideration:

- Negotiate Based on Volume and Long-Term Partnerships: Even for specialized services, establishing ongoing contracts can leverage better pricing and priority service.

- Evaluate Total Cost of Ownership (TCO): Beyond unit price, consider shipping, customs fees, turnaround time, and potential costs of damage or re-cleaning.

- Request Detailed Cost Breakdowns: Transparency on labor, materials, and logistics helps identify negotiable elements and avoid hidden fees.

- Prioritize Quality and Certifications Over Lowest Price: Wedding dresses are high-value and sentimental items; subpar cleaning can result in costly damage.

- Understand Regional Logistics Challenges: Shipping delicate garments internationally requires reliable couriers and appropriate insurance. Choose suppliers experienced with your region’s import/export requirements.

- Clarify Incoterms Early: Clear agreement on who bears shipping and customs costs avoids disputes and unexpected expenses.

- Consider Local vs. International Providers: While international specialists may offer superior expertise, local cleaners could reduce shipping costs and lead times.

Indicative Pricing Overview

As a general guide, professional wedding dress cleaning and preservation services in developed markets range approximately from USD 250 to USD 400 per dress, depending on service complexity and included options such as accessory cleaning or premium preservation packaging. Prices in emerging markets may vary due to labor and material cost differentials but ensure quality is not compromised for cost savings.

By analyzing these cost drivers and pricing influencers, international B2B buyers can make informed sourcing decisions that balance quality, cost-efficiency, and reliability when procuring wedding dress cleaning services.

Spotlight on Potential cleaners that clean wedding dresses Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘cleaners that clean wedding dresses’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for cleaners that clean wedding dresses

Critical Technical Properties for Wedding Dress Cleaners

When sourcing cleaners specialized in wedding dress care, international B2B buyers must consider several key technical properties to ensure the product meets the delicate and high-value nature of bridal garments.

-

Fabric Compatibility

Cleaners must be formulated to safely treat a wide range of delicate fabrics commonly used in wedding dresses, such as silk, satin, lace, tulle, and organza. Compatibility ensures no damage like discoloration or fiber weakening occurs. For buyers, this reduces risk of costly product returns and reputational damage. -

Stain Removal Efficacy

Wedding dresses often carry stubborn stains like wine, makeup, or dirt. The cleaner’s ability to effectively remove these without harsh chemicals is critical. Performance metrics or certifications showing efficacy on protein, oil-based, and dye stains are valuable indicators for procurement. -

pH Level and Chemical Composition

A neutral or slightly acidic pH is preferred to preserve fabric integrity and embellishments like beads or sequins. Buyers should verify that cleaners avoid aggressive solvents or bleaching agents that can degrade delicate materials. Compliance with environmental and safety regulations in target markets is also essential. -

Residue-Free Finish

Post-cleaning residue can cause fabric stiffness or attract dirt. High-quality cleaners leave no residues, preserving fabric softness and appearance. This property is important for maintaining customer satisfaction and the longevity of wedding dress preservation. -

Shelf Life and Storage Conditions

Cleaners with longer shelf lives and stable formulations under varied temperature and humidity conditions suit international logistics and storage challenges, especially in regions with diverse climates like Africa and the Middle East. Clear labeling and storage instructions help maintain product performance. -

Certification and Compliance

Certifications such as OEKO-TEX®, ISO standards, or local textile safety approvals provide assurance of quality and compliance with international trade requirements. Buyers should prioritize cleaners that align with such standards to facilitate smoother import/export processes and build trust with end clients.

Key Trade Terms for International B2B Buyers

Understanding common trade terminology is essential to navigate procurement and logistics effectively when purchasing wedding dress cleaners.

-

OEM (Original Equipment Manufacturer)

Refers to suppliers who produce cleaners that can be branded under the buyer’s label. This is important for businesses seeking private-label products to build brand identity in their local markets. -

MOQ (Minimum Order Quantity)

The smallest quantity a supplier is willing to sell per order. Knowing MOQ helps buyers plan inventory and cash flow, especially for smaller businesses or those testing new products in diverse markets. -

RFQ (Request for Quotation)

A formal inquiry sent to suppliers requesting price and terms for specific quantities and product specifications. RFQs enable buyers to compare offers and negotiate better terms. -

Incoterms (International Commercial Terms)

Standardized trade terms defining responsibilities for shipping, insurance, and tariffs between buyer and seller. Common terms like FOB (Free On Board) or CIF (Cost, Insurance, Freight) clarify who bears costs and risks during transit, aiding in cost management and risk mitigation. -

Lead Time

The total time from placing an order to receiving the product. Understanding lead times is crucial for planning seasonal demand cycles, such as peak wedding seasons in different regions. -

Batch Consistency

Refers to the uniform quality and formulation of cleaner products across production runs. Consistency ensures reliable cleaning performance, which is vital for service providers maintaining strict quality standards.

By focusing on these technical properties and trade terms, B2B buyers can make informed decisions when selecting cleaners specialized for wedding dresses. This ensures not only product effectiveness and safety but also smooth international procurement and customer satisfaction across diverse markets.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the cleaners that clean wedding dresses Sector

Market Overview & Key Trends

The global market for cleaners specializing in wedding dresses is evolving rapidly, driven by increasing consumer demand for high-quality preservation and cleaning services that cater to delicate fabrics and intricate embellishments. International B2B buyers, especially those operating in Africa (Kenya, South Africa), South America, the Middle East, and Europe, are witnessing heightened interest from bridal boutiques, event planners, and luxury retailers seeking reliable partners for post-wedding garment care.

Key market drivers include:

- Rising Wedding Expenditures: As wedding budgets grow, so does the demand for premium cleaning and preservation services, which ensure the longevity and aesthetic integrity of wedding dresses.

- Technological Advancements: Adoption of specialized cleaning technologies—such as eco-friendly solvents, gentle ultrasonic cleaning, and precision fabric care—enhances service quality and reduces damage risks, appealing to discerning clients.

- Customization & Packaging Innovation: B2B suppliers are increasingly offering customizable preservation packages, including bespoke storage solutions and accessory care, which add value for bridal stores and rental services.

- Omnichannel Sourcing: Buyers leverage digital platforms to source expert cleaners with proven track records, enabling seamless logistics management, including remote pick-up/drop-off and real-time order tracking.

- Regional Market Dynamics: In Africa and the Middle East, the rise of boutique wedding services is fueling demand for localized cleaning expertise, while European and South American markets focus on sustainable practices and certifications to meet stricter environmental regulations.

For international buyers, partnering with cleaners that demonstrate robust quality assurance protocols, transparent pricing models, and scalable service offerings is critical. Additionally, suppliers capable of handling diverse fabric types—silks, lace, beadwork—are preferred to cater to a global clientele with varying garment styles.

Sustainability & Ethical Sourcing in B2B

Sustainability has become a cornerstone in the wedding dress cleaning sector, significantly impacting B2B sourcing decisions. The environmental footprint of traditional dry-cleaning methods—often reliant on hazardous solvents like perchloroethylene (perc)—is driving a shift toward greener alternatives. Buyers are increasingly prioritizing suppliers who implement environmentally responsible practices, such as:

- Use of Eco-Friendly Solvents: Adoption of liquid CO2 cleaning, wet cleaning, and biodegradable detergents minimizes toxic emissions and water contamination.

- Energy Efficiency: Modern cleaning facilities employ energy-saving machinery and renewable energy sources, reducing carbon footprints.

- Waste Reduction: Implementing rigorous waste management and recycling programs for packaging materials and garment protectors aligns with circular economy principles.

Ethical supply chains also play a vital role, ensuring fair labor practices and safe working conditions in cleaning facilities. Certifications like Green Seal, OEKO-TEX, and ISO 14001 provide credible assurance to B2B buyers about environmental compliance and social responsibility.

For international buyers from Africa, South America, the Middle East, and Europe, sourcing from cleaners with transparent sustainability credentials not only meets regulatory expectations but also enhances brand reputation among environmentally conscious end consumers. Furthermore, sustainable practices often correlate with higher service quality and garment longevity, offering tangible business value.

Illustrative Image (Source: Google Search)

Brief Evolution and Historical Context

Historically, wedding dress cleaning was a niche service performed by local dry cleaners with limited specialization, often resulting in damage or inadequate preservation. Over the past few decades, the sector has professionalized significantly, driven by advances in textile science and consumer awareness.

The emergence of dedicated wedding dress preservation companies—many family-owned with generational expertise—has transformed the market. These specialists developed proprietary cleaning methods tailored to delicate fabrics and intricate adornments, such as beads and crystals, ensuring meticulous care.

Illustrative Image (Source: Google Search)

This evolution has created a segmented market where high-end B2B buyers seek trusted partners offering not only cleaning but also comprehensive preservation solutions, including acid-free packaging and lifetime warranties against yellowing. The rise of e-commerce and global logistics has further enabled international sourcing, allowing businesses across continents to access expert services previously limited to local markets.

In summary, international B2B buyers targeting the wedding dress cleaning sector should focus on suppliers that combine technical expertise, sustainable operations, and robust quality assurance to meet the growing demand for premium, eco-conscious garment care. Understanding regional market nuances and leveraging digital sourcing platforms will be key to navigating this dynamic industry successfully.

Related Video: HOW TO CLEAN A WEDDING DRESS – save your money $$$ and wash it at home!!

Frequently Asked Questions (FAQs) for B2B Buyers of cleaners that clean wedding dresses

-

How can I effectively vet suppliers of wedding dress cleaning services for international B2B partnerships?

To vet suppliers, begin by requesting detailed company profiles, including years of experience, expertise with delicate fabrics, and client testimonials. Verify certifications related to textile care and environmental compliance. Conduct virtual or in-person audits if possible. Ask for sample cleaning results and inquire about their quality control processes. Check references from existing international clients, especially those in similar regions like Africa or South America, to assess reliability and service standards. Supplier transparency on cleaning methods and preservation techniques is critical to ensure your end clients receive premium results. -

What customization options should I expect from wedding dress cleaning suppliers?

Top-tier suppliers offer customizable services tailored to fabric types, embellishments, and preservation preferences. Expect options such as eco-friendly cleaning solvents, hand-cleaning for delicate embroidery or beadwork, and bespoke packaging for preservation. Some suppliers can include accessories like veils or gloves in their packages or offer multi-item bundles. Discuss your market’s cultural preferences and packaging standards upfront to ensure the supplier can accommodate special requests, which can add value and differentiate your offerings in diverse markets like the Middle East or Europe. -

What are typical minimum order quantities (MOQs) and lead times when sourcing wedding dress cleaning services internationally?

MOQs vary widely depending on the supplier’s capacity and business model. Some operate on a per-dress basis, ideal for boutique or smaller volume buyers, while others require batch processing with MOQs ranging from 10 to 50 dresses. Lead times often range from 2 to 6 weeks, factoring in shipping and preservation processes. For international buyers, factor in customs clearance and transit times. Negotiate flexible MOQs and expedited services where possible, especially if your market demands quick turnaround, such as in fast-growing African urban centers. -

Which payment terms and methods are standard for international B2B transactions in wedding dress cleaning?

Suppliers typically request upfront payment or partial deposits (30-50%) before processing orders, with the balance due upon delivery or completion. Common payment methods include wire transfers, PayPal, or trade platforms offering escrow services to mitigate risk. Establish clear invoicing practices and currency terms to avoid surprises with exchange rates. For buyers in regions like South America or the Middle East, working with suppliers who accept multiple currencies or offer local payment options can streamline transactions and reduce fees. -

What quality assurance certifications should I look for in wedding dress cleaning suppliers?

Look for ISO certifications related to quality management (ISO 9001) and environmental standards (ISO 14001), which indicate disciplined operational processes. Certifications from textile or garment care bodies, such as the Drycleaning & Laundry Institute, demonstrate specialized expertise. Additionally, inquire about any industry-specific guarantees, like lifetime warranties on preservation against yellowing or fabric degradation. Robust QA protocols, including inspection checkpoints and documented cleaning procedures, ensure consistent, high-quality outcomes critical for premium wedding dress care. -

How can I manage logistics and shipping challenges when importing cleaned wedding dresses?

Partner with suppliers who provide comprehensive shipping solutions, including insured, tracked courier services and packaging designed to protect delicate garments. Clarify responsibilities for customs clearance and import duties upfront to avoid delays. For fragile items like wedding dresses, opt for suppliers experienced in international shipping with climate-controlled packaging options. Engage freight forwarders familiar with your target markets’ regulatory environments, such as in Kenya or South Africa, to streamline border procedures and minimize risk of damage or loss during transit. -

What strategies can help resolve disputes or quality issues with international wedding dress cleaning suppliers?

Establish clear contractual terms covering quality standards, delivery timelines, and dispute resolution mechanisms before engagement. Maintain thorough documentation of all communications and order specifications. If issues arise, initiate prompt dialogue to understand the root cause and negotiate corrective actions such as re-cleaning or refunds. Consider including arbitration clauses or utilizing third-party inspection services. Building long-term partnerships with transparent communication fosters trust and smoother problem resolution, particularly when managing suppliers across different time zones and cultures. -

How can I ensure compliance with environmental and safety regulations in different regions when sourcing cleaners?

Verify that suppliers adhere to international environmental standards, including safe chemical use and waste disposal practices, to protect your brand reputation. Confirm compliance with regional regulations applicable to your markets, such as REACH in Europe or local environmental laws in African countries. Request documentation of safety data sheets (SDS) for cleaning agents and inquire about sustainable practices like water recycling or solvent recovery. Promoting eco-friendly cleaning aligns with growing consumer demand and regulatory trends, adding competitive advantage in global B2B sourcing.

Strategic Sourcing Conclusion and Outlook for cleaners that clean wedding dresses

The strategic sourcing of wedding dress cleaning services demands a nuanced understanding of quality, expertise, and preservation technology. For B2B buyers across Africa, South America, the Middle East, and Europe, prioritizing providers who specialize in delicate fabrics, intricate beadwork, and offer comprehensive preservation guarantees is essential. This ensures not only exceptional service delivery but also enhances client satisfaction and brand reputation in the luxury bridal market.

Key considerations include partnering with cleaners who utilize advanced, eco-friendly cleaning methods and provide tailored solutions that respect cultural nuances and climate-related challenges affecting fabric longevity. Leveraging suppliers with proven track records, transparent processes, and scalable logistics can significantly reduce risks related to damage, delays, and compliance issues.

Illustrative Image (Source: Google Search)

Looking ahead, international buyers should actively engage in building strategic relationships with trusted wedding dress cleaning experts, emphasizing innovation and sustainable practices. Investing in collaborative partnerships that offer end-to-end solutions—from cleaning and preservation to packaging and delivery—will position businesses to meet evolving market demands and capitalize on emerging opportunities globally.

Take action now: Evaluate your sourcing criteria against these strategic imperatives to secure premium, reliable wedding dress cleaning services that support your business growth and customer loyalty in diverse international markets.