Master Sourcing Womens Dress Socks: Top Strategies for B2B

Guide to Womens Dress Socks

- Introduction: Navigating the Global Market for womens dress socks

- Understanding womens dress socks Types and Variations

- Key Industrial Applications of womens dress socks

- Strategic Material Selection Guide for womens dress socks

- In-depth Look: Manufacturing Processes and Quality Assurance for womens dress socks

- Comprehensive Cost and Pricing Analysis for womens dress socks Sourcing

- Spotlight on Potential womens dress socks Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for womens dress socks

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the womens dress socks Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of womens dress socks

- Strategic Sourcing Conclusion and Outlook for womens dress socks

Introduction: Navigating the Global Market for womens dress socks

The global market for womens dress socks is expanding rapidly, driven by rising demand for stylish, comfortable, and high-quality hosiery that complements formal and business attire. For international B2B buyers, especially those sourcing from dynamic regions such as Africa, South America, the Middle East, and Europe—including countries like Colombia and Argentina—understanding the nuances of womens dress socks is essential to securing competitive advantage and satisfying diverse consumer preferences.

Womens dress socks serve a critical role beyond mere foot coverage; they blend fashion with function, offering durability, comfort, and aesthetic appeal suitable for professional and formal settings. This product category demands attention to fabric selection, design sophistication, and manufacturing precision to meet the elevated expectations of end consumers who value both style and performance.

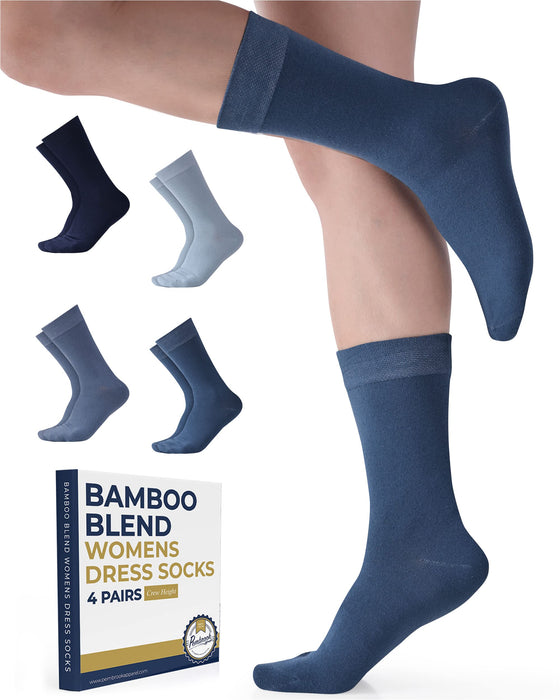

Illustrative Image (Source: Google Search)

This comprehensive guide covers every vital aspect of womens dress socks sourcing, including:

- Types and styles tailored for varying climates and cultural preferences

- Material choices such as cotton, wool, silk blends, and innovative fibers that impact comfort and longevity

- Manufacturing processes and quality control standards to ensure consistency and reduce defects

- Supplier evaluation criteria, focusing on certifications, ethical practices, and capacity to handle custom orders

- Cost structures and pricing insights to optimize budget planning

- Market trends and demand forecasts across key international regions

- A detailed FAQ section addressing common sourcing challenges and best practices

By leveraging this guide, B2B buyers can confidently navigate complex sourcing decisions, align with reputable manufacturers, and secure womens dress socks that resonate with their target markets while maximizing profitability and supply chain reliability.

Understanding womens dress socks Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Classic Cotton Dress | Lightweight cotton blend, smooth finish, solid colors | Corporate uniforms, formal wear retailers | + Breathable and comfortable; – May lack stretch and durability |

| Wool Blend Dress | Wool mixed with synthetic fibers, warm and soft | Winter collections, luxury apparel brands | + Warm and elegant; – Higher cost, potential shrinkage in washing |

| Silk & Satin Dress | Fine silk or satin yarns, smooth and glossy texture | Premium fashion boutiques, luxury gift sets | + Luxurious feel and appearance; – Delicate, requires careful care |

| Patterned & Textured | Includes ribbed, argyle, or lace patterns | Fashion-forward retailers, boutique stores | + Unique designs attract niche markets; – Complexity may increase cost |

| Compression Dress | Light compression with formal aesthetics | Medical uniform suppliers, travel apparel | + Combines style with health benefits; – Niche market, higher MOQ |

Classic Cotton Dress Socks

These socks are typically made from cotton blends that offer breathability and comfort, making them ideal for everyday office wear and corporate uniforms. Their smooth finish and solid color options cater well to bulk buyers targeting formal dress codes. For B2B buyers, cotton dress socks offer a balance of cost-effectiveness and comfort but may require additional elastane or polyester blends to improve durability and stretch.

Wool Blend Dress Socks

Wool blend socks combine natural wool with synthetic fibers to provide warmth and softness, making them a prime choice for colder climates and luxury winter collections. B2B buyers in Europe and the Middle East, where temperatures vary seasonally, often seek these for premium product lines. The main considerations include sourcing high-quality wool blends that resist shrinkage and maintain softness after washing.

Silk & Satin Dress Socks

Featuring fine silk or satin yarns, these socks are prized for their smooth, glossy texture and upscale appearance. They suit premium fashion boutiques and luxury gift sets, especially in markets with a strong demand for elegant formalwear. Buyers must weigh the benefits of exclusivity and luxury against the delicate nature of these materials, which require careful handling and higher price points.

Patterned & Textured Dress Socks

This category includes socks with ribbed, argyle, lace, or other textured patterns, catering to fashion-conscious consumers and boutique retailers. These variations allow brands to differentiate their product offerings and target niche markets in South America and Europe. The complexity of designs can increase manufacturing costs and minimum order quantities, so buyers should plan accordingly for inventory and pricing strategies.

Compression Dress Socks

Designed to combine formal aesthetics with light compression benefits, these socks appeal to buyers serving medical uniforms, travel apparel, and wellness-focused segments. They are particularly relevant in regions with growing health awareness like the Middle East and Europe. B2B buyers should consider the specialized manufacturing requirements and potentially higher MOQs when integrating compression dress socks into their product lines.

Related Video: How to Put On Compression Socks (THE EASIEST WAY!)

Key Industrial Applications of womens dress socks

| Industry/Sector | Specific Application of womens dress socks | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Corporate & Professional | Employee uniform and corporate gifting | Enhances professional appearance and brand identity | High-quality materials, consistent color and branding, durability |

| Hospitality & Tourism | Uniform accessories for hotel staff and event personnel | Promotes a polished, uniform look enhancing guest experience | Comfortable fit, breathable fabrics, easy maintenance |

| Fashion & Retail | Private label product lines and seasonal collections | Expands product portfolio with trendy, comfortable options | Design customization, trend alignment, MOQ flexibility |

| Healthcare & Wellness | Staff uniforms requiring comfort and hygiene | Improves staff comfort during long shifts, supports hygiene | Antimicrobial materials, softness, durability under frequent wash |

| Corporate Gifting & Promotions | Customized socks for marketing campaigns and client gifts | Strengthens client relationships through practical, stylish gifts | Branding options, packaging quality, timely delivery |

Corporate & Professional Sector

In corporate environments across Africa, South America, the Middle East, and Europe, womens dress socks serve as a critical component of employee uniforms and corporate gifting. Businesses seek socks that complement formal attire, enhancing a polished and professional look. High-quality materials such as fine cotton or wool blends ensure comfort during long work hours. International buyers prioritize consistent color matching and branding options to reinforce company identity. Durable construction is essential to withstand frequent wear, while customization capabilities allow businesses to tailor socks for specific corporate events or brand campaigns.

Hospitality & Tourism Industry

In hospitality, womens dress socks are integral to staff uniforms, particularly for front desk personnel, concierges, and event staff. These socks contribute to a cohesive and professional appearance that positively influences guest impressions. Buyers from regions like the Middle East and Europe focus on sourcing breathable, comfortable fabrics that accommodate long shifts and varying climates. Easy maintenance and quick drying are also valued, given the frequent laundering requirements. Suppliers offering socks with reinforced heels and toes provide added durability, reducing replacement costs for hotels and resorts.

Fashion & Retail Sector

Retailers and fashion brands targeting women’s apparel often include womens dress socks in their private label or seasonal collections. For B2B buyers in Colombia, Argentina, and other markets, these socks offer an opportunity to diversify product offerings with stylish, comfortable accessories. The ability to customize designs, colors, and patterns is critical to align with fast-changing fashion trends. Small minimum order quantities (MOQs) and flexible production timelines are attractive to emerging retailers and boutiques. Quality control is paramount to ensure socks meet consumer expectations for softness, fit, and durability.

Healthcare & Wellness Sector

Healthcare professionals require womens dress socks that prioritize comfort and hygiene. In hospitals and clinics across Europe and South America, socks that incorporate antimicrobial fibers help reduce infection risks while providing cushioning for long hours of standing or walking. Buyers emphasize softness to prevent skin irritation and durability to endure frequent washing at high temperatures. Sourcing from manufacturers who comply with healthcare textile standards and certifications ensures product reliability. These socks enhance staff well-being and contribute to a professional, uniform appearance.

Corporate Gifting & Promotions

Womens dress socks are increasingly popular as corporate gifts and promotional items in international markets. Businesses in Africa and the Middle East leverage customized socks featuring logos and unique designs to strengthen client relationships and increase brand visibility. The practicality and daily use of socks make them an effective marketing tool. Buyers look for manufacturers who offer high-quality branding options, attractive packaging, and reliable delivery schedules to meet event timelines. Ensuring cultural appropriateness in design and materials is also vital for success in diverse regions.

Related Video: LABORATORY APPARATUS AND THEIR USES

Strategic Material Selection Guide for womens dress socks

When selecting materials for women’s dress socks, international B2B buyers must carefully weigh the performance attributes, cost-effectiveness, and regional market preferences. The right material not only enhances comfort and durability but also aligns with consumer expectations and compliance standards in diverse markets such as Africa, South America, the Middle East, and Europe.

Cotton

Key Properties:

Cotton is a natural fiber known for its breathability, softness, and moisture absorption. It performs well in moderate temperature conditions and offers good comfort for everyday wear. However, it has limited elasticity and can wear out faster if not blended with synthetic fibers.

Pros & Cons:

Cotton’s primary advantage is its comfort and hypoallergenic nature, making it ideal for sensitive skin. It is widely available and cost-effective, simplifying procurement. However, pure cotton socks tend to lose shape over time and have lower durability compared to synthetic blends. Manufacturing complexity is moderate, with many factories able to handle cotton knitting efficiently.

Impact on Application:

Cotton dress socks are suitable for warm to moderate climates, making them popular in regions like South America and parts of Africa. They are less ideal for cold climates unless blended with insulating fibers. Cotton’s moisture-wicking ability helps reduce foot odor and discomfort during extended wear.

Considerations for International Buyers:

Buyers in Europe and the Middle East should verify compliance with OEKO-TEX standards to ensure no harmful chemicals are used. Cotton sourced from countries with sustainable farming practices can be a selling point in environmentally conscious markets. MOQ flexibility and cost competitiveness are important for emerging markets such as Colombia and Argentina.

Wool (Merino Wool)

Key Properties:

Merino wool is prized for its excellent thermal regulation, moisture-wicking, and natural odor resistance. It maintains warmth even when damp and offers moderate elasticity. Wool fibers are naturally resilient but require careful handling during manufacturing to avoid shrinkage.

Pros & Cons:

Wool socks provide superior comfort in cooler climates, making them ideal for European and Middle Eastern markets with colder seasons. They are durable and biodegradable, appealing to eco-conscious consumers. On the downside, wool is more expensive and requires specialized manufacturing processes, increasing lead times and costs.

Impact on Application:

Wool dress socks are best suited for fall and winter collections targeting regions with cooler temperatures. They perform well in formal settings where warmth and elegance are desired. However, wool may not be preferred in hot climates like many African countries unless blended with lighter fibers.

Considerations for International Buyers:

Buyers should ensure wool is ethically sourced, complying with certifications like RWS (Responsible Wool Standard). Wool socks may face import tariffs or require specific labeling in South America and Europe. Working with manufacturers experienced in wool can reduce quality risks and production delays.

Polyester

Key Properties:

Polyester is a synthetic fiber characterized by high durability, elasticity, and resistance to shrinking and wrinkling. It has good moisture-wicking properties but is less breathable than natural fibers. Polyester socks maintain shape well and offer excellent color retention.

Pros & Cons:

Polyester is cost-effective and easy to manufacture, enabling large-scale production with consistent quality. It enhances sock longevity and is often blended with cotton or wool to improve performance. However, polyester is less eco-friendly and may be less comfortable in hot climates due to lower breathability.

Impact on Application:

Polyester-based dress socks are suitable for markets demanding durability and vibrant designs, such as urban centers in Europe and the Middle East. They are also favored in regions with high humidity, as they dry quickly. Polyester blends are versatile for year-round use.

Considerations for International Buyers:

Buyers should assess environmental regulations related to synthetic fibers in their target markets. Certifications like OEKO-TEX and REACH compliance are critical for Europe and increasingly important in South America. MOQ and lead times are generally favorable with polyester suppliers.

Elastane (Spandex)

Key Properties:

Elastane is a highly elastic synthetic fiber used primarily to provide stretch and shape retention in socks. It is resistant to body oils, perspiration, and detergents, ensuring socks maintain fit and comfort over time.

Pros & Cons:

While elastane is not used alone, its inclusion (typically 2-5%) in blends significantly enhances fit and durability. It adds manufacturing complexity due to precise blending requirements but is essential for modern dress socks. The cost impact is moderate but justified by improved product quality.

Impact on Application:

Elastane is critical for dress socks requiring a snug, comfortable fit without sagging, especially in formal wear markets across Europe and the Middle East. Its stretch properties also benefit buyers targeting active professionals who wear dress socks for extended periods.

Considerations for International Buyers:

Ensure manufacturers use high-quality elastane to avoid early wear and loss of elasticity. Compliance with chemical safety standards (e.g., REACH in Europe) is important. Buyers in Africa and South America should verify that elastane blends meet local comfort expectations and climate adaptability.

Summary Table

| Material | Typical Use Case for womens dress socks | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Cotton | Everyday formal and casual dress socks | Soft, breathable, cost-effective | Less durable, loses shape over time | Low |

| Wool (Merino) | Cold-weather formal dress socks | Excellent warmth, moisture-wicking | Higher cost, complex manufacturing | High |

| Polyester | Durable, color-retentive dress socks | Long-lasting, quick-drying | Less breathable, eco-impact | Low to Medium |

| Elastane | Blended for stretch and fit in dress socks | Enhances fit and elasticity | Adds manufacturing complexity | Medium |

This material selection guide equips international B2B buyers with actionable insights to optimize their sourcing strategies for women’s dress socks, balancing performance, cost, and regional market demands.

In-depth Look: Manufacturing Processes and Quality Assurance for womens dress socks

Overview of the Manufacturing Process for Women’s Dress Socks

The production of women’s dress socks involves a series of carefully orchestrated stages designed to ensure comfort, durability, and style. For international B2B buyers, understanding these stages enables better supplier evaluation and product customization aligned with market demands.

1. Material Preparation

The foundation of high-quality women’s dress socks lies in the selection and preparation of raw materials. Common fibers include combed cotton, fine wool, silk blends, and synthetic fibers like polyester and elastane for elasticity. Suppliers often source these materials from certified vendors to ensure consistency in texture and strength.

- Fiber Blending: Manufacturers blend natural and synthetic fibers to achieve a balance of softness, breathability, and stretch.

- Yarn Spinning: The blended fibers undergo spinning to produce fine, uniform yarns. Yarn count and twist affect the sock’s thickness and durability.

- Dyeing: Yarn may be pre-dyed to ensure colorfastness or dyed after knitting, depending on the desired pattern and quality standards.

2. Forming the Sock

This stage primarily involves knitting the yarn into the sock’s shape using circular knitting machines designed for precision and efficiency.

- Knitting Techniques: Fine gauge knitting (higher needles per inch) is used for dress socks to create a smooth, lightweight fabric suitable for formal wear.

- Seamless Toe Construction: Advanced knitting machines produce seamless or hand-linked toes, enhancing comfort and reducing irritation.

- Reinforcement: Areas prone to wear, such as heels and toes, are reinforced with denser stitching or stronger yarn blends to improve longevity.

3. Assembly and Finishing

Once the sock’s body is knitted, it undergoes various finishing processes to ensure fit, appearance, and branding.

- Linking and Shaping: For socks not produced seamless, toe linking machines close the toe area. Socks may also be shaped using heat-setting machines to maintain proper dimensions.

- Quality Branding: Labels, logos, or custom packaging are added at this stage. For private label buyers, this offers an opportunity for brand differentiation.

- Final Treatments: Anti-bacterial, moisture-wicking, or anti-odor finishes may be applied depending on product specifications.

Quality Assurance Protocols in Women’s Dress Socks Manufacturing

Robust quality assurance (QA) and quality control (QC) frameworks are critical for maintaining product standards and meeting international market requirements. Buyers from Africa, South America, the Middle East, and Europe should prioritize suppliers with transparent and rigorous QA systems.

International and Industry Standards

- ISO 9001: This global quality management system standard ensures consistent manufacturing quality and continuous improvement. Suppliers certified with ISO 9001 demonstrate strong process controls and documentation.

- OEKO-TEX Standard 100: Ensures textiles are free from harmful substances — essential for health-conscious markets.

- BSCI and Sedex: Ethical sourcing and social compliance certifications are increasingly important for international buyers focusing on responsible procurement.

- Additional Regional Certifications: Depending on the buyer’s market, certifications such as the European CE mark (for compliance with EU safety, health, and environmental requirements) may be relevant, particularly when socks are marketed as medical or compression garments.

QC Checkpoints Throughout Production

- Incoming Quality Control (IQC): Inspection of raw materials (yarns and dyes) for consistency in color, strength, and fiber composition before production begins.

- In-Process Quality Control (IPQC): Continuous monitoring during knitting and assembly stages, focusing on fabric uniformity, stitch density, and defect detection such as runs or holes.

- Final Quality Control (FQC): Comprehensive inspection of finished socks for dimensional accuracy, color consistency, seam integrity, and packaging quality.

Common Testing Methods

- Dimensional Testing: Measurement of length, width, and elasticity to ensure fit specifications are met.

- Colorfastness Testing: Exposure to washing, rubbing, and light to verify dye stability.

- Tensile Strength and Abrasion Resistance: Testing yarn and fabric durability to simulate wear conditions.

- Pilling Resistance: Assessment of the fabric’s tendency to form pills (small fiber balls) which affect appearance.

- Odor and Anti-Bacterial Efficacy: For socks with functional finishes, lab testing confirms treatment effectiveness.

Verifying Supplier Quality Control for B2B Buyers

Given the complexity of global supply chains, B2B buyers must implement strategies to verify and monitor supplier QC systems effectively.

Audit and Inspection Strategies

- Factory Audits: Conduct on-site audits or employ third-party audit firms to evaluate manufacturing processes, labor conditions, and quality management systems.

- Sample Testing: Request pre-production and final product samples for independent lab testing to verify compliance with specifications and certifications.

- Third-Party Inspections: Utilize inspection agencies for random batch inspections and final shipment checks to ensure product consistency and reduce risks of non-compliance.

- Documentation Review: Examine supplier quality manuals, production records, and certification documents to confirm adherence to standards.

QC and Certification Nuances for Different Regions

- Africa and South America: Buyers often prioritize suppliers with flexible MOQ (Minimum Order Quantities) and certifications like OEKO-TEX and BSCI due to growing consumer awareness of sustainability and ethical sourcing.

- Middle East: Compliance with international quality standards is crucial, with additional emphasis on product safety and certifications relevant to import regulations.

- Europe (e.g., Colombia, Argentina): High demand for transparency and traceability means buyers often require ISO 9001 certification alongside environmental and social compliance certifications.

Actionable Insights for International Buyers

- Specify Material and Construction Requirements Early: Clearly define fiber blends, knitting gauge, reinforcement needs, and finishing treatments in your technical specification sheets to avoid misunderstandings.

- Request Detailed QC Protocols: Ask suppliers for their IQC, IPQC, and FQC procedures and past audit reports to assess their quality management rigor.

- Leverage Third-Party Quality Assurance: Independent inspections and lab testing provide an unbiased view of product quality and compliance.

- Understand Regional Certification Demands: Align your sourcing strategy with the certification expectations of your target markets to facilitate smoother customs clearance and consumer trust.

- Build Long-Term Supplier Relationships: Establishing a partnership with manufacturers that prioritize quality and transparency leads to better product consistency and innovation over time.

By mastering the manufacturing nuances and quality assurance protocols of women’s dress socks, international B2B buyers can confidently source products that meet their market’s functional and aesthetic demands while safeguarding supply chain integrity.

Related Video: Garments Full Production Process | Order receive to Ex-Factory | Episode 2

Comprehensive Cost and Pricing Analysis for womens dress socks Sourcing

Cost Components in Women’s Dress Socks Sourcing

Understanding the cost structure behind women’s dress socks is critical for international B2B buyers aiming to optimize procurement budgets while ensuring quality.

-

Materials: The primary cost driver. Common materials include cotton, wool, polyester, and elastane. Premium fibers such as mercerized cotton or silk blends increase costs but enhance comfort and durability. Buyers should assess the material composition carefully, as it directly influences product quality and price.

-

Labor: Varies significantly by manufacturing country. Countries with lower labor costs (e.g., parts of Asia) may offer competitive pricing but require scrutiny on quality standards. Labor costs encompass knitting, reinforcement of heels and toes, and finishing processes.

-

Manufacturing Overhead: Includes factory utilities, machine maintenance, and administrative expenses. Efficient factories with modern equipment can reduce overhead per unit, especially at scale.

-

Tooling and Sampling: Initial design and tooling (e.g., knitting machines setup for specific patterns) can incur upfront costs. Sample production is essential for quality validation and typically charged separately.

-

Quality Control (QC): Inspection, testing for durability, colorfastness, and compliance with certifications adds to costs but mitigates risks of returns and reputational damage.

-

Logistics and Shipping: Freight costs depend on shipment size, mode (sea, air), and destination. Import duties, customs clearance, and local delivery expenses must be factored in, especially for buyers in Africa, South America, and the Middle East.

-

Supplier Margin: Includes manufacturer profit and any intermediary fees. Negotiation can influence margins, particularly for large volume orders or long-term partnerships.

Key Price Influencers for Women’s Dress Socks

Several factors directly impact the final pricing offered by suppliers:

-

Order Volume & Minimum Order Quantities (MOQs): Larger orders generally yield better unit pricing. Typical MOQs range from 1,000 to 2,000 pairs per design, but some manufacturers offer lower MOQs for startups or private labels.

-

Specifications and Customization: Custom colors, logos, packaging, and special designs increase cost due to tooling, additional labor, and longer lead times.

-

Material Quality and Certifications: Socks made from organic cotton, bamboo, or with eco-friendly dyes cost more. Certifications like ISO 9001, BSCI, or OEKO-TEX add assurance but may raise prices.

-

Supplier Location and Reputation: Established manufacturers with proven track records and certifications tend to price higher but reduce risk. Emerging manufacturers may offer aggressive pricing but require due diligence.

-

Incoterms: Terms such as FOB, CIF, or DDP affect the distribution of shipping costs and risks. Buyers should understand these terms to anticipate landed cost accurately.

Actionable Buyer Tips for International B2B Procurement

-

Negotiate Beyond Price: Focus on total value including lead times, quality guarantees, and after-sales support. For buyers in Colombia, Argentina, and other regions, leveraging local sourcing agents or trade platforms can improve negotiation leverage.

-

Evaluate Total Cost of Ownership (TCO): Consider not only unit price but also shipping, customs duties, potential quality issues, and inventory holding costs. A lower upfront price may lead to higher overall expenses.

-

Request Samples Early: Paying for quality samples ($30–$100) helps validate supplier claims and avoid costly mistakes.

-

Leverage Volume Flexibility: If your initial volume is below typical MOQs, seek manufacturers specializing in startups or D2C brands who offer lower MOQs with slightly higher unit costs.

-

Understand Pricing Nuances by Region: For buyers in Africa and the Middle East, shipping delays and customs can add hidden costs. In Europe, compliance with stricter regulations and certifications may justify higher prices.

-

Use Incoterms Strategically: For first-time international orders, FOB (Free On Board) can minimize surprises, but for complex logistics, DDP (Delivered Duty Paid) offers greater convenience at a premium.

Indicative Pricing Disclaimer

Pricing for women’s dress socks varies widely based on the above factors. Indicative FOB prices from major manufacturing hubs typically range from $0.50 to $2.00 per pair depending on material quality and customization level. Buyers should conduct due diligence and obtain multiple quotes tailored to their specific requirements.

By thoroughly analyzing these cost elements and price influencers, international B2B buyers can make informed sourcing decisions that balance cost-efficiency, quality, and supply chain reliability for women’s dress socks.

Spotlight on Potential womens dress socks Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘womens dress socks’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for womens dress socks

Critical Technical Properties of Women’s Dress Socks

Understanding the key technical properties of women’s dress socks is essential for international B2B buyers to ensure product quality, durability, and customer satisfaction. Below are the most important specifications to consider:

-

Material Composition and Grade

Dress socks typically use blends of cotton, wool, silk, polyester, and elastane. The grade of these fibers (e.g., combed cotton vs. regular cotton) directly affects softness, breathability, and longevity. For B2B buyers, specifying premium material grades guarantees a higher-end product that meets the expectations of discerning consumers in Europe, the Middle East, and South America. -

Yarn Count and Gauge

Yarn count refers to the thickness of yarn used, while gauge is the number of needles per inch in the knitting machine. Higher gauge numbers mean finer, denser knitting, resulting in smoother, thinner, and more elegant socks suitable for formal wear. Buyers should request specific gauge details to align with market preferences for dress socks’ appearance and comfort. -

Sock Density and Weight (Denier or GSM)

The density or weight of the sock fabric, often measured in grams per square meter (GSM) or denier, impacts durability and comfort. Dress socks are generally lightweight but must balance thinness with sufficient durability to avoid quick wear, especially at the heel and toe. Buyers should confirm these measurements to ensure the socks meet durability standards without compromising style. -

Elasticity and Recovery (Elastane Percentage)

The percentage of elastane or spandex affects how well the sock fits and retains its shape. A typical range is 2-5%, providing stretch without sagging. Proper elasticity is crucial for comfort and professional appearance, especially in markets where formality is prized. Buyers should specify elastane content to ensure consistent fit and quality. -

Reinforcement Zones (Heel and Toe Strengthening)

Reinforced heels and toes extend the product lifespan by preventing holes in high-friction areas. This feature is vital for B2B buyers targeting premium or mid-tier markets, where durability is a key selling point. Confirm with manufacturers the reinforcement techniques and materials used to meet end-user expectations. -

Colorfastness and Dye Quality

High-quality dyeing processes ensure that colors do not fade or bleed, maintaining the sock’s aesthetic appeal over time. For international buyers, especially in regions with high humidity like Africa or the Middle East, colorfastness is a critical quality parameter to check during product development.

Common Trade Terminology in Women’s Dress Socks Procurement

Navigating international B2B trade requires familiarity with industry jargon that affects ordering, pricing, and logistics. Below are key terms every buyer should understand:

-

OEM (Original Equipment Manufacturer)

Refers to manufacturers who produce socks based on a buyer’s design and specifications, including branding. OEM partnerships allow buyers to offer unique products without owning manufacturing facilities, critical for brands in Africa and South America seeking customization. -

MOQ (Minimum Order Quantity)

The smallest number of units a manufacturer is willing to produce in one order. MOQs often range from 1,000 to 2,000 pairs for dress socks. Buyers must balance MOQ requirements with budget and inventory constraints, particularly important for startups or smaller distributors. -

RFQ (Request for Quotation)

A formal inquiry sent to manufacturers to obtain price quotes and terms based on specific product requirements. RFQs should include technical specs such as material composition, gauge, and packaging details to receive accurate offers. -

Incoterms (International Commercial Terms)

Standardized trade terms published by the International Chamber of Commerce that define responsibilities between buyers and sellers for shipping, insurance, and customs. Common terms include FOB (Free on Board) and CIF (Cost, Insurance, Freight). Understanding Incoterms helps buyers control costs and risks in international shipments. -

Lead Time

The total time from order placement to delivery. Typical lead times for dress socks manufacturing range from 30 to 45 days, including production and shipping. Buyers should plan accordingly to maintain inventory flow and avoid stockouts. -

Private Label

A business model where buyers sell socks produced by a manufacturer under their own brand name. This term is vital for companies in emerging markets aiming to build local brands with international quality standards.

By mastering these technical properties and trade terms, international B2B buyers from Africa, South America, the Middle East, and Europe can make informed decisions, negotiate effectively, and source women’s dress socks that align perfectly with their market demands and quality expectations.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the womens dress socks Sector

Market Overview & Key Trends

The global womens dress socks market is experiencing steady growth driven by evolving fashion sensibilities, increased professional workforce participation, and rising demand for functional yet stylish accessories. International B2B buyers from regions such as Africa, South America, the Middle East, and Europe—particularly countries like Colombia and Argentina—are witnessing shifts in consumer preferences toward premium quality, comfort, and aesthetic variety in dress socks.

Key market drivers include:

- Rising Disposable Income & Urbanization: Growing middle classes in emerging economies are fueling demand for refined apparel items, including womens dress socks that complement formal and office wear.

- Fashion Innovation: There is an increasing appetite for diverse patterns, colors, and fabric blends (e.g., cotton with elastane or silk blends) that marry style with comfort.

- Technological Advancements: Automation and digital design tools are enabling manufacturers to offer rapid prototyping, customization, and shorter lead times, aligning with the needs of D2C brands and retailers globally.

- Shift Toward Small MOQ Manufacturing: Emerging brands and startups from these regions prefer suppliers offering flexible minimum order quantities (MOQs), enabling market testing without heavy upfront investments.

For buyers in Africa and South America, sourcing from Asia (notably China and India) remains prevalent due to cost advantages and manufacturing expertise. However, buyers are increasingly scrutinizing suppliers for quality certifications and ethical compliance. In Europe and the Middle East, demand is leaning toward premium and sustainable products, with consumers valuing transparency and traceability in supply chains.

Sourcing trends to watch:

- Customization & Private Labeling: B2B buyers are leveraging manufacturers’ ability to produce bespoke designs, logos, and packaging to enhance brand differentiation.

- Integrated Supply Chains: Partnerships that provide end-to-end solutions—from material sourcing to finished product delivery—are gaining traction, reducing complexity for international buyers.

- E-commerce & Digital Marketplaces: Online sourcing platforms are streamlining vendor discovery and communication, critical for buyers in geographically dispersed regions.

Sustainability & Ethical Sourcing in B2B

Sustainability is increasingly becoming a decisive factor in the womens dress socks sector, influencing sourcing decisions across global markets. Environmental concerns such as water usage, chemical pollution, and carbon emissions in textile manufacturing are prompting B2B buyers to prioritize eco-friendly practices and materials.

Key aspects of sustainability and ethical sourcing include:

- Eco-friendly Materials: Organic cotton, bamboo fibers, and recycled yarns are gaining popularity as they reduce environmental impact and cater to conscious consumers.

- Certifications to Look For: Buyers should verify supplier adherence to standards such as OEKO-TEX® Standard 100 (for chemical safety), Global Organic Textile Standard (GOTS), and Fair Trade certifications that ensure ethical labor practices.

- Supply Chain Transparency: Increasingly, buyers demand traceability from raw material sourcing to final production, ensuring compliance with environmental and social governance (ESG) criteria.

- Waste Reduction & Circularity: Manufacturers adopting zero-waste knitting technologies and recycling programs align with global circular economy goals, offering buyers a competitive edge.

For B2B buyers from regions like Europe and the Middle East, where consumer demand for sustainable fashion is robust, partnering with manufacturers that demonstrate verifiable green credentials is essential. Meanwhile, buyers in Africa and South America are beginning to integrate sustainability into their sourcing criteria, balancing cost and ethical imperatives.

Investing in sustainable womens dress socks not only mitigates reputational risks but also opens access to premium market segments willing to pay a premium for responsible products. This trend underscores the strategic importance of sustainability as a long-term sourcing priority.

Evolution of Womens Dress Socks: A B2B Perspective

Historically, womens dress socks were considered a niche accessory, primarily designed for functionality and modesty within formal attire. Over the decades, the sector has evolved significantly, influenced by broader fashion trends, material innovations, and changing workplace cultures.

In the early 20th century, womens dress socks were predominantly made from wool and cotton blends, emphasizing durability over design. The post-industrial era introduced synthetic fibers like nylon and elastane, improving fit and longevity. The late 20th and early 21st centuries marked the rise of fashion-forward designs, with brands experimenting with colors, patterns, and textures to complement diverse wardrobes.

For B2B buyers, understanding this evolution highlights the importance of sourcing partners capable of blending traditional quality with contemporary aesthetics and technical advancements. This historical context also explains the current emphasis on customization, premium materials, and sustainable production, reflecting a mature market that values both heritage and innovation.

Related Video: International Trade Explained

Frequently Asked Questions (FAQs) for B2B Buyers of womens dress socks

-

How can I effectively vet suppliers of womens dress socks from international markets like China or India?

Start by verifying the supplier’s certifications such as ISO 9001, BSCI, or Sedex to ensure compliance with quality and ethical standards. Request product samples to evaluate material quality, workmanship, and comfort. Check references or reviews from other international buyers, particularly those who have experience in Africa, South America, or the Middle East. Utilize sourcing agents or third-party inspections to audit factories on-site. Confirm the supplier’s ability to meet customization requirements and delivery timelines before finalizing agreements. -

What customization options are typically available for womens dress socks in B2B sourcing?

Most manufacturers offer customization in terms of fabric blend (e.g., cotton, wool, silk, bamboo), colors, patterns, and branding such as logos or labels. You can request specific yarn gauges, thickness, and reinforcements on toes and heels for durability. Some suppliers also provide eco-friendly materials or special finishes like anti-odor or moisture-wicking. Clarify minimum order quantities (MOQs) for custom designs and request prototypes to ensure your branding and design expectations are met before bulk production. -

What are typical minimum order quantities (MOQs) and lead times for womens dress sock orders?

MOQs often range between 1,000 to 2,000 pairs per design or color, though some manufacturers, especially in India and China, offer lower MOQs for startups or smaller brands. Lead times typically span 30 to 45 days from order confirmation to shipment, depending on order complexity and customization. Plan for additional time if samples or design approvals are needed. Negotiate MOQs and timelines upfront to align with your market launch schedules and inventory management strategies. -

Which payment methods are safest and most convenient for international B2B transactions?

Bank wire transfers (T/T) remain the most common and secure method for large orders, especially with established suppliers. PayPal or escrow services offer additional security for smaller orders or initial transactions, providing dispute resolution options. Always confirm payment terms in the contract, such as deposits (usually 30-50%) and balance payments upon shipment or delivery. Use letters of credit for higher-value shipments to mitigate risks. Ensure clear communication with suppliers about payment milestones to avoid delays. -

What quality assurance (QA) measures should I insist on when sourcing womens dress socks internationally?

Require manufacturers to implement in-line and final inspections to check for defects, sizing accuracy, and color consistency. Insist on testing for durability aspects like reinforced toes and heels, elasticity retention, and fabric pilling. Request third-party lab certifications for material composition and safety standards relevant to your target markets. Establish quality benchmarks in your contract and consider periodic factory audits or hiring local QA agents to monitor production. Document non-conformance procedures to swiftly address issues.

Illustrative Image (Source: Google Search)

-

Are there specific certifications or compliance standards relevant to womens dress socks for international markets?

Yes, certifications such as OEKO-TEX Standard 100 ensure textiles are free from harmful substances, which is critical for markets in Europe and the Middle East. ISO 9001 certifies quality management systems, while BSCI or Sedex focus on social compliance and ethical manufacturing practices. Some regions may require compliance with REACH (EU chemical regulations) or local import regulations on labeling and safety. Confirm these certifications with suppliers to facilitate smooth customs clearance and market acceptance. -

What logistics considerations should B2B buyers from Africa, South America, or the Middle East keep in mind?

Factor in the shipping mode (sea freight is cost-effective but slower; air freight is faster but more expensive) and port infrastructure in your region. Understand customs clearance requirements, duties, and taxes specific to womens dress socks in your country. Work with freight forwarders experienced in handling textile imports to avoid delays. Negotiate Incoterms (e.g., FOB, CIF) clearly to define responsibilities. Plan inventory with buffer time for potential delays due to seasonal surges or regulatory inspections. -

How should disputes or quality issues be managed with overseas womens dress sock suppliers?

Establish clear contractual terms covering product specifications, delivery timelines, payment schedules, and penalties for non-compliance. Document all communications and agreements in writing. Upon receiving defective goods, conduct a detailed inspection and share evidence (photos, reports) with the supplier immediately. Negotiate solutions such as replacements, refunds, or discounts. For persistent issues, involve arbitration or legal counsel familiar with international trade laws. Maintaining open communication and building trust reduces dispute risks.

Illustrative Image (Source: Google Search)

Strategic Sourcing Conclusion and Outlook for womens dress socks

Strategic sourcing of women’s dress socks demands a thorough understanding of material quality, manufacturing capabilities, and supplier reliability. For international B2B buyers from Africa, South America, the Middle East, and Europe, prioritizing suppliers who offer customization, consistent quality standards, and compliance with ethical certifications is paramount. Leveraging partnerships with manufacturers that provide flexibility in minimum order quantities and efficient lead times can significantly enhance supply chain responsiveness and market competitiveness.

Key takeaways include:

– Selecting premium fabrics like cotton, wool, or blends with elastane ensures durability and comfort that end consumers expect.

– Engaging suppliers who support private labeling and design customization empowers brands to differentiate in diverse markets.

– Verifying certifications such as ISO 9001 or BSCI mitigates risks related to quality and social compliance, which is increasingly important for global trade.

– Considering manufacturers with experience serving multiple regions facilitates smoother communication and logistical arrangements.

Looking ahead, B2B buyers are encouraged to adopt a strategic sourcing mindset that balances cost-efficiency with quality and innovation. Embracing emerging trends such as sustainable materials and agile manufacturing will position businesses to meet evolving consumer demands in women’s dress socks. Now is the time to forge strong, transparent supplier relationships that enable scalability and resilience in a dynamic global marketplace.