Master Sourcing Plus Size Babydoll Dress: Top Strategies

Guide to Plus Size Babydoll Dress

- Introduction: Navigating the Global Market for plus size babydoll dress

- Understanding plus size babydoll dress Types and Variations

- Key Industrial Applications of plus size babydoll dress

- Strategic Material Selection Guide for plus size babydoll dress

- In-depth Look: Manufacturing Processes and Quality Assurance for plus size babydoll dress

- Comprehensive Cost and Pricing Analysis for plus size babydoll dress Sourcing

- Spotlight on Potential plus size babydoll dress Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for plus size babydoll dress

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the plus size babydoll dress Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of plus size babydoll dress

- Strategic Sourcing Conclusion and Outlook for plus size babydoll dress

Introduction: Navigating the Global Market for plus size babydoll dress

The global demand for plus size babydoll dresses is experiencing notable growth, driven by increasing consumer awareness of inclusive fashion and the desire for stylish, comfortable apparel that caters to diverse body types. For international B2B buyers—especially those operating in dynamic markets across Africa, South America, the Middle East, and Europe—capitalizing on this trend requires a strategic understanding of product variations, sourcing channels, and market-specific preferences.

Plus size babydoll dresses blend flattering silhouettes with versatile design elements, making them a staple in contemporary wardrobes. Their appeal lies in combining comfort with fashion-forward aesthetics, offering opportunities for retailers and wholesalers to address underserved customer segments. This guide provides a comprehensive roadmap to sourcing these garments effectively, covering key aspects such as:

- Diverse styles and fabric options tailored to regional climates and consumer tastes.

- Manufacturing standards and quality control protocols ensuring consistent product excellence.

- Reliable supplier identification and evaluation for efficient supply chain management.

- Cost structures and pricing strategies aligned with competitive market positioning.

- Insights into emerging market trends and consumer behavior across target regions.

- Frequently asked questions addressing common sourcing challenges and compliance considerations.

By leveraging this resource, international buyers will gain actionable insights to navigate complexities in production, quality assurance, and supplier partnerships. This empowers them to make informed decisions that optimize product assortment, enhance brand reputation, and maximize profitability in the expanding plus size babydoll dress market.

Understanding plus size babydoll dress Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

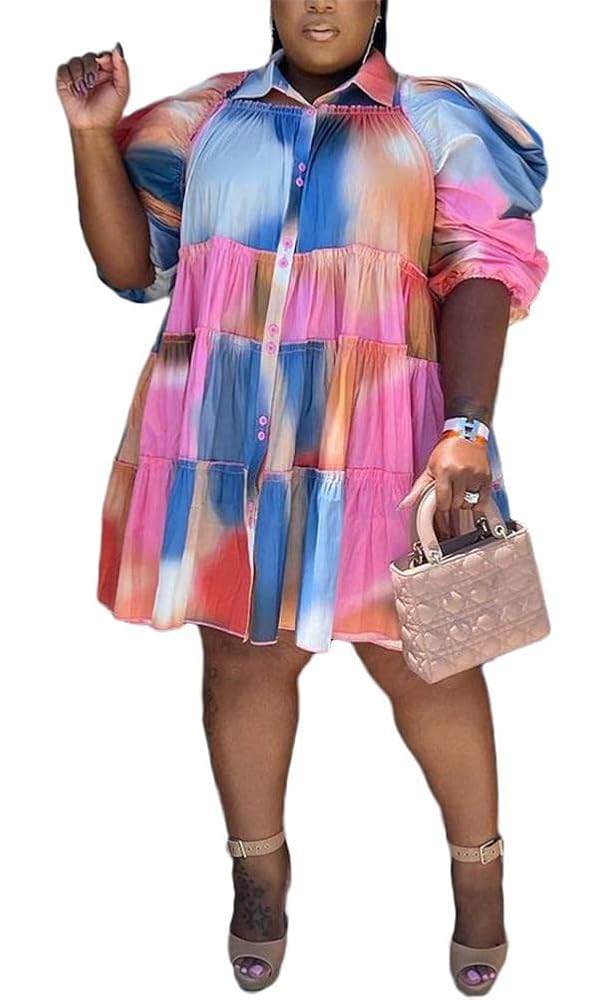

| Mini Babydoll Dress | Short hemline, loose fit, often with puff or ruffle details | Casual wear, summer collections, youth-focused markets | + Trendy and versatile; – Seasonal demand, limited formal appeal |

| Maxi Babydoll Dress | Floor-length, flowy silhouette, sometimes off-shoulder or tiered | Resort wear, evening collections, luxury segments | + Elegant and flattering; – Higher production costs, niche market |

| Puff-Sleeve Babydoll | Characterized by voluminous sleeves, often combined with smock style | Fashion-forward retail, boutique lines | + Stylish and distinctive; – Complex tailoring, increased material use |

| Shirt-Style Babydoll | Button-down front, collar, resembles oversized shirt dress | Office casual, urban fashion, transitional seasons | + Functional and comfortable; – May require precise sizing for fit |

| Embroidered/Embellished Babydoll | Decorative embroidery or applique detailing, often on organza or mesh | Premium segments, ethnic-inspired collections | + High perceived value; – Longer production lead time, costlier |

Mini Babydoll Dress

The mini babydoll dress is a staple for warm climates and casual wear, favored for its short hemline and playful, loose fit. Its lightweight design makes it ideal for markets with hot weather, such as parts of Africa and South America. For B2B buyers, this type offers a high turnover potential in fast fashion and streetwear segments. However, its seasonal nature limits year-round sales, and buyers should anticipate demand fluctuations. Sourcing from manufacturers with quick turnaround and variety in colors and prints can maximize market responsiveness.

Maxi Babydoll Dress

Maxi babydoll dresses appeal to luxury and resort markets, featuring floor-length cuts and elegant, flowy fabrics. These dresses suit buyers targeting upscale boutiques or evening wear collections, including Middle Eastern and European clients who value modesty combined with style. Production complexity and fabric costs are higher, so buyers should focus on quality suppliers with expertise in delicate materials and embroidery. The maxi style’s broad appeal in formal and leisurewear segments justifies investment in premium manufacturing.

Puff-Sleeve Babydoll

This variation is distinguished by its voluminous sleeves, adding a dramatic, fashion-forward silhouette. It is popular in urban and boutique markets, particularly in Europe and Turkey, where statement pieces are in demand. From a B2B perspective, puff-sleeve babydolls require skilled tailoring and more fabric, impacting cost and lead time. Buyers should work with manufacturers capable of precision craftsmanship and flexible production runs to accommodate trend-driven cycles.

Shirt-Style Babydoll

Combining the ease of a babydoll dress with the structure of a shirt, this style features button fronts and collars, offering a versatile option for office casual or transitional season wear. It appeals to markets seeking comfort with a polished look, making it suitable for Middle Eastern and South American urban consumers. B2B buyers benefit from its functional appeal, but sizing accuracy is critical due to the fitted elements. Partnering with manufacturers experienced in plus-size tailoring ensures better fit and customer satisfaction.

Embroidered/Embellished Babydoll

Embellished babydoll dresses incorporate decorative details like embroidery or applique, often on sheer fabrics such as organza. These are well-suited for premium or ethnic-inspired collections, which have strong demand in diverse markets including African and Middle Eastern regions. For B2B buyers, these dresses offer higher margins but require longer production times and careful quality control. Sourcing from specialized manufacturers who can handle intricate embellishments is essential for maintaining product integrity and brand reputation.

Related Video: HOW TO STYLE A BABYDOLL DRESS FOR PLUS SIZE CURVES! SHOP LACENLEOPARD

Key Industrial Applications of plus size babydoll dress

| Industry/Sector | Specific Application of plus size babydoll dress | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion Retail | Seasonal plus-size summer collections featuring babydoll dresses | Attracts plus-size consumers with trendy, comfortable options | Fabric breathability, size inclusivity, and trend alignment |

| E-commerce Platforms | Plus-size babydoll dresses as part of curated online plus-size apparel | Expands product range, increases customer engagement | Quality control, reliable supply chain, and customizable designs |

| Hospitality & Tourism | Uniforms or casual wear options for plus-size staff in resorts/hotels | Enhances employee comfort and professional appearance | Durability, ease of maintenance, and cultural adaptability |

| Event Management | Plus-size babydoll dresses for themed events and promotional giveaways | Enhances brand image and customer inclusivity | Bulk order capacity, consistent sizing, and vibrant design options |

| Wholesale Distributors | Stocking plus-size babydoll dresses for regional fashion markets | Meets growing demand in emerging markets | Competitive pricing, compliance with local regulations, and fabric sourcing |

Fashion Retail

In the fashion retail industry, plus size babydoll dresses serve as key seasonal items, especially for summer collections targeting diverse body types. Retailers in Africa, South America, the Middle East, and Europe find these dresses essential to cater to the increasing demand for trendy yet comfortable plus-size apparel. The lightweight and breezy design solves the problem of limited stylish options for plus-size customers, providing retailers a competitive edge. Buyers should prioritize sourcing breathable fabrics and ensure size inclusivity to meet regional climate and cultural preferences.

Illustrative Image (Source: Google Search)

E-commerce Platforms

Online retailers leverage plus size babydoll dresses to diversify their apparel offerings and attract a broader customer base. These dresses are popular for their effortless style and fit, making them ideal for digital marketing campaigns aimed at plus-size consumers worldwide. For international B2B buyers, ensuring product quality and consistency is critical to reduce returns and enhance customer satisfaction. Customizable designs and reliable supply chains are vital considerations to adapt to fast-changing fashion trends and regional preferences in target markets such as Turkey and Thailand.

Hospitality & Tourism

In the hospitality sector, plus size babydoll dresses are increasingly used as part of casual or semi-formal uniforms for staff in resorts and hotels. This application addresses the need for comfortable, flattering attire that respects diversity and enhances employee morale. Businesses benefit from improved staff appearance and comfort, which translates into better customer service. Sourcing durable, easy-care fabrics that withstand frequent washing and align with the cultural aesthetics of regions like the Middle East and Europe is essential for buyers.

Event Management

Event organizers use plus size babydoll dresses for themed parties, corporate events, and promotional giveaways to foster inclusivity and enhance brand presence. These dresses solve the challenge of providing stylish plus-size options that resonate with diverse audiences. Bulk purchasing capabilities and consistency in sizing are critical for international buyers who need to outfit large groups efficiently. Additionally, vibrant designs that appeal across cultures in Africa and South America can increase the impact of marketing efforts.

Wholesale Distributors

Wholesale distributors targeting emerging markets rely on plus size babydoll dresses to meet the growing demand for plus-size fashion. These dresses offer an accessible entry point for distributors to expand their product lines and cater to underserved consumer segments. Competitive pricing and compliance with local textile and import regulations are key sourcing considerations. Buyers should also focus on sustainable fabric sourcing and certifications to appeal to environmentally conscious customers in Europe and other regions.

Related Video: LABORATORY APPARATUS AND THEIR USES

Strategic Material Selection Guide for plus size babydoll dress

Cotton: The Classic Choice for Comfort and Breathability

Key Properties: Cotton is a natural fiber known for its excellent breathability, moisture absorption, and softness. It performs well in warm climates due to its ability to wick sweat away from the skin. It has moderate durability and is easily dyeable, making it versatile for various colors and prints.

Pros & Cons: Cotton is highly favored for plus size babydoll dresses because it offers comfort and an easy drape, essential for flattering loose fits. It is relatively affordable and widely available globally. However, cotton wrinkles easily and can shrink if not pre-treated. It also tends to absorb moisture, which can lead to longer drying times and potential mildew in humid environments.

Impact on Application: Cotton’s breathability and softness make it ideal for summer collections targeting hot regions such as Africa and South America. However, for buyers in more humid or rainy climates (e.g., parts of the Middle East or Southeast Asia), cotton dresses may require treatments or blends to improve quick-drying properties and reduce shrinkage.

B2B Considerations: International buyers should verify cotton quality grades (e.g., combed, organic) and compliance with standards like OEKO-TEX or GOTS for sustainable sourcing. European and Middle Eastern markets increasingly demand certifications for organic cotton. Additionally, cotton sourced from Turkey or Egypt is often preferred for premium lines due to superior fiber length and softness.

Polyester: Durable and Cost-Effective Synthetics

Key Properties: Polyester is a synthetic fiber known for its high durability, wrinkle resistance, and quick-drying nature. It resists shrinking and stretching, maintaining shape well under various conditions. It is less breathable than natural fibers but excels in color retention and resistance to mildew.

Pros & Cons: Polyester offers excellent durability and ease of care, making it cost-effective for mass production. It is lighter and less prone to damage from sweat or humidity, which suits tropical and arid climates. On the downside, polyester can feel less comfortable against the skin and may trap heat, which can be a drawback in extremely hot regions.

Impact on Application: Polyester plus size babydoll dresses are suitable for buyers targeting markets where durability and low maintenance are priorities, such as fast fashion retailers in Europe or urban centers in South America. Blending polyester with cotton or rayon can improve comfort and breathability while retaining durability.

B2B Considerations: Buyers should check for compliance with international standards such as ASTM D123 or ISO 2076 for fiber identification and quality. In regions like the Middle East and Europe, there is growing interest in recycled polyester to meet sustainability goals. Sourcing from certified suppliers ensures traceability and market acceptance.

Rayon (Viscose): Softness with a Silky Feel

Key Properties: Rayon is a semi-synthetic fiber made from regenerated cellulose, offering a soft, smooth texture with excellent drape. It is breathable and comfortable, often used to mimic silk or cotton feel. Rayon is moderately durable but sensitive to water and prone to shrinking if not handled properly.

Pros & Cons: Rayon’s luxurious feel and flowy drape make it ideal for stylish plus size babydoll dresses that require a delicate appearance. It is generally more affordable than silk but less durable than polyester or cotton. Rayon garments require gentle care and may not hold up well in very humid or wet conditions without special finishes.

Impact on Application: Rayon dresses are popular in fashion-forward markets in Europe and South America where aesthetic appeal is key. However, buyers targeting hot and humid climates such as parts of Africa or Southeast Asia should consider blends or finishes that improve moisture resistance and durability.

B2B Considerations: International buyers should ensure rayon suppliers comply with environmental regulations due to chemical processing involved in production. Certifications like OEKO-TEX or bluesign® can assure safer chemical use. Additionally, buyers in Europe and Turkey may require compliance with REACH regulations for chemical safety.

Linen: Premium Natural Fiber for Breathability and Texture

Key Properties: Linen is a natural fiber derived from flax plants, known for its exceptional breathability, moisture-wicking ability, and textured appearance. It is stronger than cotton but wrinkles easily. Linen performs well in hot climates due to its cooling properties.

Pros & Cons: Linen plus size babydoll dresses offer a premium, natural aesthetic with excellent comfort in warm weather. It is durable and hypoallergenic but tends to wrinkle and crease, which may affect the garment’s look. Linen is generally more expensive and requires careful manufacturing to avoid stiffness.

Impact on Application: Linen is highly suitable for buyers focusing on luxury or eco-friendly collections in Europe and upscale markets in the Middle East and South America. Its natural cooling effect is ideal for tropical and arid climates. However, linen’s higher cost and care requirements may limit its use in budget-conscious segments.

B2B Considerations: Buyers should verify linen fiber origin and quality, as European flax (e.g., Belgian or French) is often preferred for premium products. Compliance with EU textile labeling regulations and sustainability certifications can enhance marketability. For African markets, sourcing linen blends may balance cost and performance.

| Material | Typical Use Case for plus size babydoll dress | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Cotton | Casual, breathable summer dresses for warm climates | Soft, breathable, widely accepted | Prone to wrinkling, shrinkage, slower drying | Low |

| Polyester | Durable, wrinkle-resistant dresses for mass-market and humid regions | Durable, quick-drying, low maintenance | Less breathable, can trap heat | Low to Medium |

| Rayon (Viscose) | Fashion-forward, soft, flowy dresses with silky feel | Luxurious drape and softness | Sensitive to moisture, less durable | Medium |

| Linen | Premium, breathable dresses with natural texture | Excellent breathability and cooling | Wrinkles easily, higher cost, requires careful handling | High |

In-depth Look: Manufacturing Processes and Quality Assurance for plus size babydoll dress

Manufacturing Processes of Plus Size Babydoll Dresses

The production of plus size babydoll dresses involves a series of well-defined stages to ensure both aesthetic appeal and comfort, especially important given the garment’s loose, flowing silhouette tailored for plus sizes. Understanding these stages enables B2B buyers to assess manufacturer capabilities and product quality.

1. Material Preparation

This foundational stage involves sourcing and preparing the fabric and trims. Common materials include lightweight cotton blends, chiffon, rayon, or soft polyester, chosen for breathability and drape. Fabric inspection for defects such as holes, color inconsistency, or weaving flaws is critical here. Additionally, components like lace, ribbons, buttons, and elastic bands are procured and quality-checked.

2. Pattern Making and Cutting

Given the plus size range, pattern grading is crucial to maintain proportion and fit across sizes. Patterns are digitally created or manually drafted, with attention to the babydoll’s signature empire waist and flowy skirt. Cutting is often done via computerized cutting machines for precision and fabric efficiency, minimizing waste and ensuring consistent panel sizes.

3. Forming and Assembly

Assembly starts with sewing the bodice and skirt sections separately, often using overlock and flatlock stitching techniques to accommodate stretch fabrics and reduce seam bulk. Key techniques include gathering or pleating the skirt for volume, attaching puff sleeves or ruffles where applicable, and integrating elastic or drawstring details for adjustable fits. Seam reinforcements at stress points improve durability.

4. Finishing

Finishing processes enhance the garment’s aesthetic and durability. This includes hemming, attaching labels, adding decorative elements (e.g., embroidery or appliqués), and final pressing. Some manufacturers incorporate anti-wrinkle or anti-pilling treatments to elevate product quality. Packaging is adapted to protect delicate fabrics during shipping, often with eco-friendly materials favored by international markets.

Quality Assurance Frameworks and Checkpoints

For B2B buyers, verifying that plus size babydoll dresses meet high-quality standards is essential to reduce returns, maintain brand reputation, and ensure customer satisfaction across diverse markets.

International Standards and Certifications

– ISO 9001: The global benchmark for quality management systems, ensuring consistent production processes and continuous improvement. Buyers should prioritize suppliers with ISO 9001 certification as it reflects robust quality controls and traceability.

– OEKO-TEX Standard 100: Especially relevant for fabric safety, this certification guarantees textiles are free from harmful substances, a key consideration for markets with strict consumer protection laws (Europe, Middle East).

– GOTS (Global Organic Textile Standard): Increasingly demanded by eco-conscious buyers, this certifies organic fiber content and sustainable manufacturing practices.

– While CE or API certifications are generally not applicable to apparel, compliance with regional labeling and safety regulations (e.g., EU Textile Regulation) is mandatory.

Quality Control Checkpoints

– Incoming Quality Control (IQC): Inspection of raw materials (fabric, trims) upon arrival to detect defects before production. This includes fabric colorfastness, shrinkage tests, and physical defects.

– In-Process Quality Control (IPQC): Continuous monitoring during sewing and assembly stages to ensure stitching integrity, correct measurements, and proper construction. Real-time adjustments reduce waste and rework.

– Final Quality Control (FQC): Comprehensive inspection of finished garments checking seam strength, dimensional accuracy, color consistency, and overall appearance. Defects like loose threads, uneven hems, or incorrect sizing are identified here.

Common Testing Methods

– Dimensional Measurement: Ensuring garments conform to the specified size charts, critical for plus size apparel to provide a flattering fit.

– Colorfastness Testing: Exposure to washing, rubbing, and light to evaluate color retention, vital for multi-colored or patterned babydoll dresses.

– Fabric Strength and Stretch Tests: Assessing tensile strength and elasticity to guarantee durability and comfort.

– Shrinkage Tests: Verifying fabric stability after laundering to avoid customer dissatisfaction.

Verifying Supplier Quality Control: Practical Strategies for B2B Buyers

International buyers, particularly from Africa, South America, the Middle East, and Europe, face challenges such as long supply chains, varying regulatory requirements, and cultural differences in quality expectations. Here are actionable approaches to ensure supplier QC credibility:

Illustrative Image (Source: Google Search)

1. Conduct On-Site Audits

Engage third-party inspection agencies or appoint experienced quality inspectors to visit factories. Audits should evaluate manufacturing capabilities, QC processes, worker skill levels, and compliance with certifications. For buyers unable to travel, virtual factory audits via video calls are increasingly effective.

2. Request Detailed QC Reports and Documentation

Suppliers should provide comprehensive quality inspection reports, including IQC, IPQC, and FQC results, alongside fabric test certificates (e.g., OEKO-TEX). These documents help buyers verify adherence to agreed standards before shipment.

3. Third-Party Laboratory Testing

Independent labs can perform fabric and finished garment tests to validate supplier claims on colorfastness, shrinkage, and chemical safety. This is especially crucial for buyers targeting stringent markets like the EU or the Gulf Cooperation Council (GCC).

4. Sample Development and Pre-Production Prototypes

Before bulk production, buyers should approve samples that represent final quality. This allows for physical assessment of fit, fabric handfeel, and construction, mitigating risks of mass production errors.

5. Leverage Technology and Supply Chain Transparency Tools

Digital platforms offering real-time QC data, batch tracking, and compliance certifications enable buyers to monitor quality remotely, fostering trust and prompt issue resolution.

Quality Control Nuances for International Markets

Each regional market brings unique considerations that B2B buyers must factor into their QC strategies:

-

Africa and South America: Buyers often prioritize durability and ease of care due to climate and washing conditions. They should ensure suppliers test for fabric resilience and shrinkage extensively. Logistics challenges also necessitate robust packaging and damage-proof finishing.

-

Middle East: High emphasis on premium fabric quality and compliance with chemical safety due to hot climates and sensitive skin considerations. Certifications like OEKO-TEX and adherence to Islamic modesty standards (if applicable) are significant.

-

Europe (e.g., Turkey): Stringent environmental and safety regulations require suppliers to have ISO 9001 and GOTS certifications. Buyers may also demand transparency on labor practices and sustainability, integrating social compliance audits into QC.

-

Thailand and Southeast Asia: As a growing garment hub, manufacturers here excel in advanced sewing technology and quick turnaround but buyers should verify QC through factory audits and insist on regular IPQC checkpoints due to rapid production cycles.

Summary: Key Takeaways for B2B Buyers

- Understand the full manufacturing workflow of plus size babydoll dresses, emphasizing fabric selection, precise pattern grading, and skilled assembly techniques.

- Insist on internationally recognized quality certifications such as ISO 9001 and OEKO-TEX to safeguard product standards and consumer safety.

- Implement a multi-tiered QC approach covering raw material inspection (IQC), in-line monitoring (IPQC), and final product evaluation (FQC).

- Leverage third-party audits, sample approvals, and lab testing to independently verify supplier quality claims and compliance.

- Adapt QC expectations to regional market requirements, balancing durability, compliance, and cultural preferences.

- Utilize digital tools and transparent communication to maintain quality oversight across global supply chains.

By integrating these manufacturing and quality assurance insights, international B2B buyers can confidently source plus size babydoll dresses that meet diverse market demands and deliver consistent customer satisfaction.

Related Video: Amazing Garment Manufacturing Process from Fabric to Finished Product Inside the Factory

Comprehensive Cost and Pricing Analysis for plus size babydoll dress Sourcing

When sourcing plus size babydoll dresses, understanding the comprehensive cost and pricing structure is crucial for international B2B buyers aiming to optimize procurement and maximize profitability. This analysis breaks down key cost components, influential pricing factors, and practical buyer tips tailored for markets in Africa, South America, the Middle East, and Europe.

Key Cost Components in Plus Size Babydoll Dress Production

-

Materials: The primary cost driver is fabric selection, typically lightweight cotton, chiffon, or polyester blends suited for the babydoll style. Plus size garments require additional yardage, increasing material costs proportionally. Trims such as lace, elastic bands, buttons, and embroidery further add to material expenses.

-

Labor: Labor intensity varies by complexity—simple smock styles cost less than those with intricate ruching or embroidery. Labor rates differ significantly by manufacturing location; for example, Southeast Asia offers competitive wages compared to Europe, impacting overall costs.

-

Manufacturing Overhead: This includes factory utilities, equipment depreciation, and indirect labor. Efficient factories with modern technology often have lower overhead per unit, influencing pricing.

-

Tooling and Setup: Initial costs for pattern making, sample development, and custom machinery setup must be amortized across production runs. Higher customization or unique plus size grading increases tooling costs.

-

Quality Control (QC): Rigorous QC ensures compliance with size specifications and fabric quality, crucial for plus size apparel where fit consistency is paramount. QC processes add cost but reduce returns and enhance brand reputation.

-

Logistics: International shipping, import duties, customs clearance, and last-mile delivery costs significantly affect landed cost, especially for buyers in Africa and South America where logistics infrastructure may be less developed.

-

Margin: Manufacturers and suppliers incorporate profit margins based on order size, brand positioning, and market demand. Buyers should expect markup variations depending on supplier scale and exclusivity.

Influential Pricing Factors for International Buyers

-

Order Volume and Minimum Order Quantity (MOQ): Larger orders typically secure lower per-unit prices due to economies of scale. However, plus size lines sometimes face higher MOQs because of specialized grading, impacting inventory risk.

-

Product Specifications and Customization: Customized designs, exclusive prints, or added embellishments increase costs. Buyers should balance uniqueness against cost efficiency.

-

Material Quality and Certifications: Organic or sustainable fabrics, OEKO-TEX certifications, and compliance with environmental or social standards command premium pricing but appeal to conscious consumers in Europe and the Middle East.

-

Supplier Reliability and Location: Established suppliers with proven quality and on-time delivery may charge higher prices but reduce supply chain risks. Regional proximity can reduce lead times and logistics costs, important for African and South American buyers.

-

Incoterms and Payment Terms: The choice of Incoterms (e.g., FOB, CIF, DDP) shifts cost and risk responsibilities. Buyers must understand these to accurately compare supplier quotes and anticipate additional charges.

Strategic Buyer Tips for Cost-Efficient Sourcing

-

Negotiate Beyond Unit Price: Engage suppliers on payment terms, packaging, freight consolidation, and QC procedures. Negotiating bundled services can lower total procurement costs.

-

Calculate Total Cost of Ownership (TCO): Consider all costs from production to delivery, including potential tariffs and currency fluctuations. TCO analysis prevents surprises that erode margins.

-

Leverage Sampling and Prototyping: Invest in detailed samples to verify fit and fabric quality, reducing costly reworks, particularly important for plus size garments with complex sizing.

-

Prioritize Supplier Transparency: Choose manufacturers providing clear cost breakdowns and production timelines, facilitating better budgeting and order planning.

-

Account for Regional Logistics Nuances: African and South American buyers should factor in longer transit times and potential customs delays. Partnering with suppliers offering integrated global shipping solutions can mitigate these challenges.

-

Be Mindful of MOQ Flexibility: Smaller brands or startups may seek suppliers willing to accommodate lower MOQs or staggered deliveries to reduce inventory risk.

Indicative Pricing Overview

For reference, plus size babydoll dresses sourced from major Asian manufacturers typically range from $5 to $25 per unit depending on fabric quality, design complexity, and order volume. Premium European suppliers may charge significantly more, often starting at $30 upwards due to higher labor and compliance costs. Buyers should treat these figures as indicative; actual pricing varies with specification and negotiation outcomes.

By thoroughly analyzing cost drivers and pricing influencers, international B2B buyers can strategically source plus size babydoll dresses that meet quality and budget requirements while navigating the complexities of global apparel supply chains.

Spotlight on Potential plus size babydoll dress Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘plus size babydoll dress’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for plus size babydoll dress

Key Technical Properties of Plus Size Babydoll Dresses

Understanding the technical specifications of plus size babydoll dresses is essential for international B2B buyers to ensure product quality, consistency, and market suitability. Here are the critical properties to consider:

-

Fabric Composition and Quality

The primary material—commonly cotton blends, polyester, or organza—determines comfort, durability, and drape. For plus size dresses, fabrics with good stretch and breathability are preferred to ensure fit and wearer comfort. Buyers should request fabric certifications and grade details to verify quality standards. -

Sizing and Fit Tolerance

Plus size garments require precise grading to accommodate a broader range of body shapes. Tolerance refers to the allowable deviation in measurements (e.g., ±1 cm). Tight control of sizing tolerance prevents customer returns and dissatisfaction. Suppliers should provide detailed size charts with clear measurement tolerances. -

Seam and Stitching Strength

Given the relaxed, flowing style of babydoll dresses, seam durability is crucial, especially for plus size cuts which bear more stress. Look for reinforced stitching and double-needle seams to maintain garment integrity during wear and washing. -

Color Fastness

The ability of fabric dyes to resist fading or bleeding during washing and exposure to sunlight is vital for maintaining product appeal. Buyers should request test reports on color fastness to ensure longevity, particularly for vibrant or dark colors popular in various markets. -

Weight and Thickness (GSM – Grams per Square Meter)

Fabric weight affects the dress’s fall and opacity. For babydoll dresses, a lightweight fabric (typically 120-180 GSM) creates the desired airy look but must balance opacity to avoid see-through issues. Buyers should confirm GSM specifications to match end-market expectations. -

Finish and Embellishments

Many babydoll dresses feature details like puff sleeves, ruffles, or embroidery. The quality of these finishes impacts the garment’s perceived value and durability. Ensure suppliers use industry-standard finishing techniques and inspect prototypes for embellishment durability.

Common Trade Terminology in Plus Size Babydoll Dress Sourcing

Familiarity with key industry terms will streamline communication with manufacturers and improve negotiation outcomes:

-

OEM (Original Equipment Manufacturer)

Refers to manufacturers producing garments based on the buyer’s design and specifications. OEM services allow for private labeling and customization, crucial for brands seeking differentiation in plus size fashion. -

MOQ (Minimum Order Quantity)

The smallest number of units a supplier is willing to produce per style or order. Understanding MOQ helps buyers manage inventory risk and budget, especially when testing new plus size designs in diverse markets. -

RFQ (Request for Quotation)

A formal inquiry sent to suppliers to obtain price, lead time, and production details. A well-prepared RFQ with clear specifications ensures accurate and comparable bids, facilitating better sourcing decisions. -

Incoterms (International Commercial Terms)

Standardized trade terms defining responsibilities for shipping, insurance, and customs between buyer and seller (e.g., FOB, CIF). Clear agreement on Incoterms reduces misunderstandings and logistical risks in international transactions. -

Tech Pack

A detailed document including sketches, materials, measurements, and construction notes sent to manufacturers. For plus size babydoll dresses, a comprehensive tech pack ensures the supplier understands the fit and design nuances critical to this segment. -

Lead Time

The total time from order confirmation to product delivery. Managing lead times is vital for seasonal fashion items like babydoll dresses, where market timing impacts sales success.

By focusing on these technical properties and mastering the relevant trade terminology, B2B buyers in Africa, South America, the Middle East, and Europe can confidently source high-quality plus size babydoll dresses that meet their customers’ expectations and strengthen their supply chain partnerships.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the plus size babydoll dress Sector

Market Overview & Key Trends

The global plus size babydoll dress market is experiencing robust growth, driven by increasing demand for inclusive fashion and comfort-centric apparel. International B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, are witnessing a surge in consumer preference for versatile, flattering silhouettes that cater to diverse body types. This trend is propelled by greater social awareness around body positivity and a shift toward casual yet stylish dressing, especially for warmer climates where babydoll dresses excel as breezy, easy-to-wear options.

Key market drivers include the rise of e-commerce platforms facilitating cross-border trade, enabling buyers to access a broad range of manufacturers specializing in plus size apparel, including babydoll dresses. In sourcing, buyers are prioritizing suppliers who offer customization capabilities—such as fabric selection, pattern adjustments, and sizing inclusivity—to differentiate their product lines. Countries like Turkey and Thailand stand out as strategic sourcing hubs due to their established textile industries, skilled labor force, and competitive pricing. African and South American markets are also emerging as promising sources, especially for ethically produced and culturally inspired designs.

Illustrative Image (Source: Google Search)

Technological advancements in fabric innovation, digital pattern making, and virtual sampling are streamlining production cycles and reducing time-to-market. Buyers benefit from these developments by engaging with manufacturers who leverage 3D prototyping and AI-powered trend forecasting, enabling more responsive and demand-driven inventory management. Additionally, there is an increasing trend toward integrating sustainable materials and production methods, which not only meet regulatory standards in Europe and the Middle East but also appeal to environmentally conscious consumers worldwide.

Sustainability & Ethical Sourcing in B2B

Sustainability is no longer optional but a critical factor shaping supplier selection and product development in the plus size babydoll dress sector. The environmental footprint of apparel production—ranging from water consumption and chemical usage to waste generation—has prompted B2B buyers to seek transparent supply chains and eco-friendly certifications. Key certifications such as GOTS (Global Organic Textile Standard), OEKO-TEX, and Bluesign are becoming essential benchmarks, ensuring that fabrics like organic cotton, Tencel, and recycled polyester meet stringent environmental and social criteria.

Ethical sourcing involves partnering with manufacturers committed to fair labor practices, safe working conditions, and community engagement. Buyers targeting markets in Europe and the Middle East often face stringent compliance requirements for ethical standards, which also resonate with the values of emerging African and South American consumers. Transparent traceability systems, including blockchain-enabled tracking, are increasingly adopted to verify origin and sustainability claims, mitigating risks related to greenwashing.

For plus size babydoll dresses, sustainability extends beyond materials to encompass design efficiency and durability. Suppliers focusing on zero-waste pattern cutting, low-impact dyeing techniques, and modular designs that facilitate recycling or upcycling offer significant value to buyers. This approach not only reduces environmental impact but also aligns with evolving consumer demands for responsible fashion, helping B2B buyers build brand equity and loyalty in competitive markets.

Evolution and Historical Context

The babydoll dress originated in the mid-20th century as a lingerie-inspired garment, blending youthful innocence with subtle sensuality. Traditionally designed as a short, loose-fitting dress, it was initially associated with intimate wear but gradually evolved into mainstream fashion. Its transformation into a plus size staple reflects broader shifts in the apparel industry toward inclusivity and body positivity.

For B2B buyers, understanding this evolution is crucial as it informs product positioning and marketing strategies. The plus size babydoll dress today embodies a fusion of comfort, style, and empowerment, appealing to a wide demographic seeking both aesthetics and ease. This historical context underlines the garment’s adaptability, making it a resilient product category adaptable to various cultural preferences and climate conditions across international markets.

Related Video: Global Trends Chapter 2 | Part 1 | Video Posted!

Frequently Asked Questions (FAQs) for B2B Buyers of plus size babydoll dress

-

How can I effectively vet suppliers for plus size babydoll dresses to ensure quality and reliability?

Begin by requesting detailed product catalogs and samples to assess quality firsthand. Verify the supplier’s certifications related to textiles and manufacturing standards, such as ISO or OEKO-TEX. Conduct background checks via trade platforms, ask for client references, and evaluate their export experience, especially regarding your target region. Consider suppliers who offer transparent communication and can provide comprehensive production and quality control documentation. Partnering with manufacturers that specialize in plus size apparel often ensures better fit and fabric expertise. -

What customization options are typically available when ordering plus size babydoll dresses in bulk?

Most manufacturers offer extensive customization including fabric choice, colors, prints, sizing ranges, and embellishments like lace or embroidery. You can also request private label services, custom tags, and packaging tailored to your brand identity. Discuss design tweaks such as sleeve styles, dress length, and neckline adjustments to meet your market’s preferences. Confirm the supplier’s capability to accommodate your design files or samples and clarify any minimum customization order requirements before committing. -

What are the typical minimum order quantities (MOQs) and lead times for plus size babydoll dress orders?

MOQs vary widely but generally range from 100 to 500 units per style or color variant. Some manufacturers accommodate smaller MOQs for startups but often at higher per-unit costs. Lead times usually span 30 to 60 days from sample approval to shipment, depending on order complexity and factory workload. Always confirm MOQs and lead times upfront and build in buffer time for sample development, quality inspections, and shipping to avoid supply chain disruptions. -

Which payment methods are safest and most common for international B2B transactions in apparel sourcing?

Common payment methods include Letters of Credit (L/C), Telegraphic Transfers (T/T), PayPal, and escrow services. L/Cs offer strong buyer protection but involve more administrative steps. T/T is widely accepted but requires trust in the supplier, so splitting payments (e.g., 30% upfront, 70% after inspection) is advisable. Using reputable trade platforms with escrow features can further mitigate risks. Always confirm payment terms and currency details in the contract to avoid misunderstandings.

-

What quality assurance processes should I expect from plus size babydoll dress manufacturers?

Reputable manufacturers implement multiple quality checkpoints including fabric inspection, in-line production checks, and final garment inspection. Request detailed QA protocols and certifications such as ISO 9001 to ensure compliance with international quality standards. Third-party inspections before shipment can be arranged for added assurance. It is critical to define quality parameters upfront—like stitch density, colorfastness, and sizing accuracy—to avoid disputes later. -

Are there specific certifications or compliance standards I should verify when sourcing plus size babydoll dresses?

Yes, look for certifications like OEKO-TEX Standard 100 for fabric safety and non-toxicity, ISO 9001 for quality management, and BSCI or WRAP for ethical manufacturing practices. Certifications relevant to your market (e.g., EU REACH compliance) are also important. These attest to responsible sourcing and product safety, which can be a competitive advantage in markets such as Europe and the Middle East. Always request copies of these certificates before finalizing deals. -

What logistical considerations are important when importing plus size babydoll dresses from Asia or other manufacturing hubs?

Consider shipping methods (air freight for speed, sea freight for cost efficiency) and their impact on lead times and costs. Clarify Incoterms (e.g., FOB, CIF) to understand your responsibilities for freight, insurance, and customs clearance. Partner with freight forwarders experienced in your target region to navigate import regulations, tariffs, and documentation requirements. Plan for potential delays during peak seasons and ensure your supplier provides timely shipping notifications and tracking. -

How should I handle disputes or quality issues after receiving a shipment?

Establish clear contract terms covering return policies, defect thresholds, and remedies before ordering. Upon receipt, conduct immediate quality inspections and document any issues with photos and detailed reports. Communicate promptly with the supplier, providing evidence and requesting resolution—whether replacements, refunds, or discounts. For ongoing partnerships, consider third-party mediation or arbitration services. Maintaining transparent communication and detailed records is key to resolving disputes efficiently and preserving business relationships.

Strategic Sourcing Conclusion and Outlook for plus size babydoll dress

The plus size babydoll dress segment presents a compelling opportunity for international B2B buyers aiming to meet the growing demand for stylish, comfortable, and inclusive apparel. Key sourcing considerations include prioritizing manufacturers with expertise in plus size garment construction, ensuring fabric choices that blend breathability and durability, and leveraging customization options to differentiate product offerings. Buyers from Africa, South America, the Middle East, and Europe should strategically evaluate suppliers who offer scalable production, ethical manufacturing practices, and flexible MOQ terms to optimize inventory management and market responsiveness.

Strategic sourcing in this niche is not merely about cost-efficiency but also about aligning with partners who understand fit, comfort, and trend dynamics unique to plus size fashion. Collaborations that emphasize innovation—such as sustainable fabrics and adaptive designs—can enhance brand value and consumer loyalty in diverse markets.

Looking ahead, the plus size babydoll dress market is poised for expansion as inclusive fashion continues to gain traction globally. International buyers are encouraged to proactively engage with forward-thinking manufacturers, invest in quality-driven sourcing, and harness emerging market trends to capture a loyal customer base. Embracing a strategic, partnership-oriented sourcing approach will be key to unlocking sustainable growth and competitive advantage in this vibrant apparel category.