Master Sourcing Authentic 1930s Dress Styles for Global B2B

Guide to 1930S Dress

- Introduction: Navigating the Global Market for 1930s dress

- Understanding 1930s dress Types and Variations

- Key Industrial Applications of 1930s dress

- Strategic Material Selection Guide for 1930s dress

- In-depth Look: Manufacturing Processes and Quality Assurance for 1930s dress

- Comprehensive Cost and Pricing Analysis for 1930s dress Sourcing

- Spotlight on Potential 1930s dress Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for 1930s dress

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the 1930s dress Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of 1930s dress

- Strategic Sourcing Conclusion and Outlook for 1930s dress

Introduction: Navigating the Global Market for 1930s dress

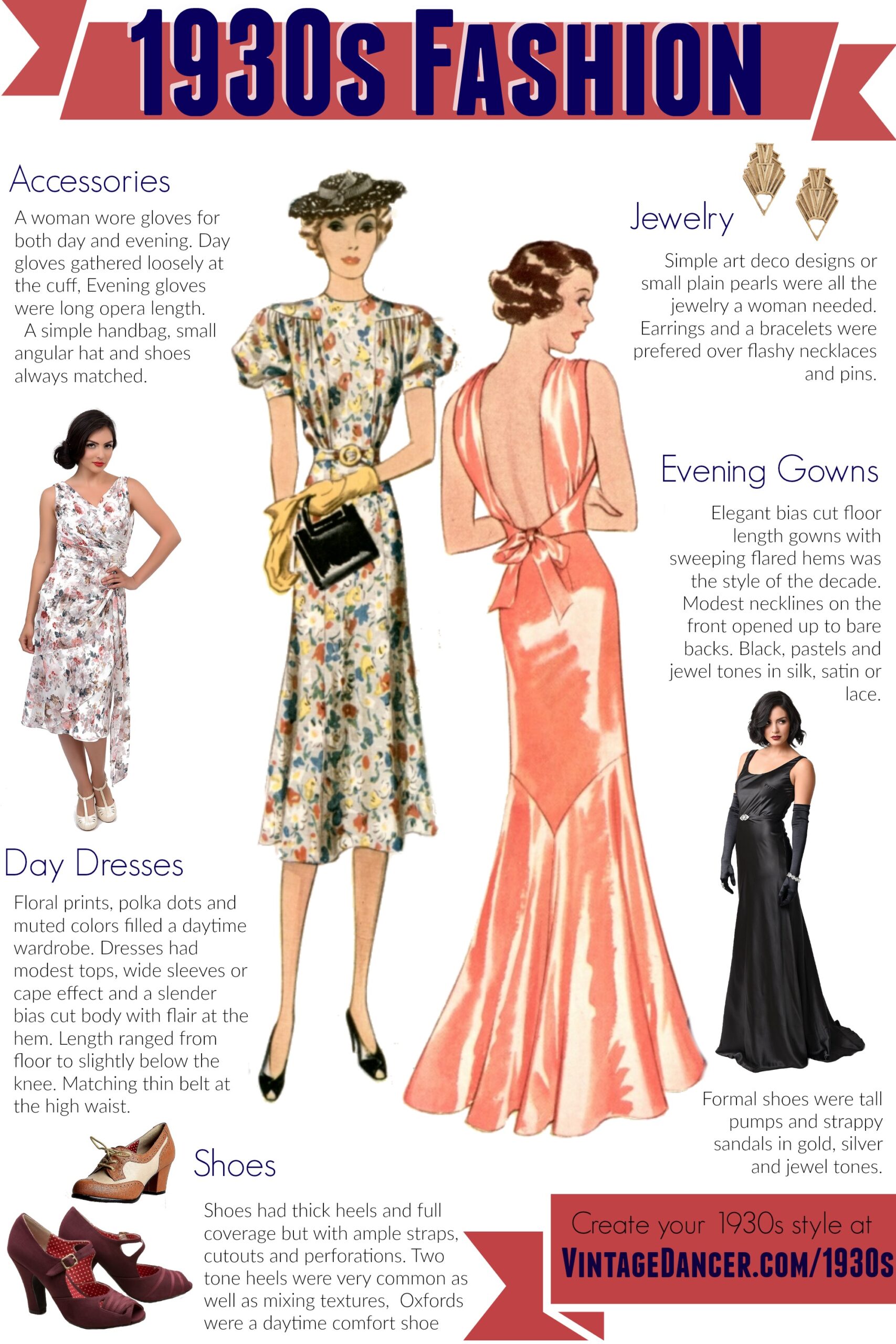

The 1930s dress market represents a unique intersection of vintage charm, historical significance, and enduring style appeal—making it a compelling category for international B2B buyers targeting diverse global markets. For buyers in Africa, South America, the Middle East, and Europe, understanding the nuances of 1930s fashion is essential to sourcing products that resonate with both niche collectors and mainstream consumers seeking timeless elegance and authenticity.

This guide offers an in-depth exploration of the 1930s dress sector, covering critical aspects such as the variety of dress styles—from bias-cut gowns to tailored daywear—the distinctive materials and fabrics used, and the manufacturing and quality control processes that ensure durability and period accuracy. It also provides detailed insights into supplier landscapes, cost structures, and prevailing market trends worldwide, empowering buyers to identify reliable partners and negotiate effectively.

With the global appetite for vintage-inspired and sustainable fashion on the rise, this resource equips you with actionable knowledge to navigate complexities like sourcing authentic or reproduction garments, adapting to regional preferences, and complying with import regulations. Additionally, a curated FAQ section addresses common sourcing challenges, helping you mitigate risks and optimize supply chain efficiency.

By leveraging this comprehensive guide, international B2B buyers can confidently make informed decisions, secure competitive pricing, and expand their offerings with 1930s dresses that appeal across continents—transforming vintage fashion into a strategic business advantage.

Understanding 1930s dress Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Bias-Cut Gowns | Fabric cut diagonally for fluid, body-hugging drape; silk/satin | Luxury evening wear, high-end boutiques | Pros: Elegant, flattering fit; Cons: Requires delicate fabric handling, higher cost |

| Day Dresses | Midi length, fitted waist, puff sleeves, ruffles, cotton blends | Mass-market ready-to-wear, retail chains | Pros: Versatile, affordable; Cons: Less exclusive, seasonal trends impact sales |

| Hollywood Glamour Dresses | Long, backless or sleeveless bias-cut gowns inspired by film stars | Premium fashion events, specialty stores | Pros: High glamour appeal; Cons: Limited daily wearability, niche market |

| Casual Sportswear Dresses | Skirt-like shorts, striped knits, relaxed fit | Sportswear and casual fashion retailers | Pros: Comfort and practicality; Cons: Less formal, seasonal demand fluctuations |

| Surrealist/Statement Dresses | Bold colors (e.g., shocking pink), shoulder pads, artistic prints | Fashion-forward boutiques, designer labels | Pros: Unique, eye-catching; Cons: Limited mass appeal, higher production complexity |

Bias-Cut Gowns

Bias-cut gowns are iconic for their diagonal fabric cuts, which provide a luxurious, body-skimming silhouette. Typically crafted from silk or satin, these dresses suit high-end fashion markets and luxury evening wear segments. For B2B buyers, sourcing bias-cut gowns requires attention to fabric quality and skilled craftsmanship to maintain the drape and fit. These gowns appeal to affluent customers seeking sophistication but may present challenges in inventory due to their delicate materials and higher price points.

Day Dresses

Day dresses of the 1930s are characterized by midi lengths, fitted waists, and feminine details like puff sleeves and ruffles. Made often from cotton blends or textured fabrics, they cater well to ready-to-wear markets and mass retail. B2B buyers benefit from their versatility and relatively lower production costs, making them suitable for broad consumer bases. However, these dresses can be subject to seasonal fashion cycles and may require frequent design updates to maintain relevance.

Hollywood Glamour Dresses

Inspired by silver screen icons, these dresses emphasize long, flowing bias cuts with backless or sleeveless designs. Their primary market is upscale fashion events and specialty boutiques targeting consumers desiring vintage glamour. Buyers should consider the niche appeal and higher price sensitivity, as these dresses are often event-specific and less practical for everyday wear. Investing in authentic or high-quality reproductions can command premium pricing but may limit volume sales.

Casual Sportswear Dresses

Reflecting the increasing casualization of women’s wardrobes in the 1930s, these dresses incorporate relaxed fits, skirt-like shorts, and striped knit tops. Ideal for sportswear and casual fashion retailers, they offer comfort and practicality, appealing to younger or active demographics. From a B2B perspective, these garments can be produced using cost-effective materials with simpler construction, but buyers must anticipate fluctuating demand linked to seasonal activities and regional lifestyle trends.

Surrealist/Statement Dresses

These dresses stand out with bold elements such as shocking pink hues, shoulder pads, and artistic or surrealist prints. Originating from designers like Elsa Schiaparelli, they attract fashion-forward consumers and boutique labels seeking unique, avant-garde inventory. B2B buyers should evaluate the balance between creativity and commercial viability, as these pieces often require specialized production and carry higher risks due to limited mass-market appeal. However, they can enhance brand differentiation and attract niche clientele.

Related Video: 100 Years of Fashionable Womenswear: 1830s – 1930s | V&A

Key Industrial Applications of 1930s dress

| Industry/Sector | Specific Application of 1930s dress | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Film & Television | Period costume design for historical productions | Authenticity enhances storytelling and audience engagement | Fabric quality, accurate design replication, supplier expertise in vintage styles |

| Fashion & Apparel Retail | Vintage-inspired collections and niche market offerings | Differentiation through unique, timeless styles | Sourcing bias-cut fabrics, skilled tailoring, compliance with ethical sourcing |

| Event & Entertainment | Themed events, vintage parties, and cultural exhibitions | Increased attendance and customer satisfaction via immersive experiences | Availability of diverse sizes, culturally adaptable designs, durable materials |

| Textile & Fabric Industry | Production of bias-cut textiles and vintage fabric reproductions | Expansion into niche markets, innovation in fabric techniques | Access to specialized looms, knowledge of 1930s fabric textures and finishes |

| Tourism & Heritage | Museum exhibitions and historical reenactments | Educational value and enhanced visitor engagement | Authentic materials, period-accurate garment construction, collaboration with historians |

The film and television industry frequently utilizes 1930s dresses to achieve historical accuracy in period dramas and documentaries. Authentic costume design based on the 1930s enhances the visual storytelling, making productions more credible and appealing to global audiences. For international buyers, especially from regions like Africa and South America where vintage fashion is gaining cultural interest, sourcing from suppliers who specialize in period-accurate garments is crucial. Key considerations include fabric authenticity, expert tailoring, and the ability to replicate intricate details such as bias cuts and shoulder pads.

In fashion and apparel retail, 1930s dress styles inspire vintage and retro collections that attract niche consumer segments seeking timeless elegance. Retailers across Europe and the Middle East can leverage these designs to stand out in competitive markets. Buyers should prioritize sourcing bias-cut silks and satins, as well as partnering with manufacturers skilled in reproducing complex silhouettes. Ethical sourcing and sustainable production methods also enhance brand reputation in these regions.

The event and entertainment sector benefits from 1930s dresses in themed parties, vintage fairs, and cultural exhibitions. These garments create immersive experiences that boost event attendance and customer satisfaction. For buyers in diverse markets such as Indonesia and Spain, it’s important to consider garment durability and adaptability to various body types and cultural preferences. Ensuring a wide size range and sourcing breathable fabrics suitable for different climates will enhance the application’s success.

Within the textile and fabric industry, there is a growing demand for reproductions of 1930s fabrics, especially bias-cut textiles that require specialized weaving techniques. This niche expansion allows fabric producers to innovate and cater to designers and manufacturers focused on vintage fashion revival. International buyers should evaluate suppliers’ technical capabilities, including access to traditional looms and expertise in fabric finishes that replicate the 1930s texture and drape.

Finally, the tourism and heritage sector uses 1930s dresses for museum displays and historical reenactments, enriching educational programs and visitor engagement. Buyers from Europe and the Middle East often collaborate with historians to ensure accuracy and authenticity. Key sourcing factors include the use of period-appropriate materials and traditional garment construction methods, which help preserve cultural heritage while appealing to tourists interested in history and fashion.

Related Video: Introduction to Uses and Gratifications Theory

Strategic Material Selection Guide for 1930s dress

Silk

Key Properties: Silk is a natural protein fiber known for its smooth texture, excellent drape, and moderate tensile strength. It has good moisture absorbency but low elasticity and moderate thermal insulation, making it comfortable in warm to moderate climates. Silk is delicate and sensitive to prolonged exposure to sunlight and moisture.

Pros & Cons: Silk’s luxurious sheen and fluidity made it the fabric of choice for iconic 1930s bias-cut gowns, prized for elegance and comfort. It is lightweight and breathable but requires careful handling during manufacturing due to its delicate nature. Silk is relatively expensive and less durable compared to synthetic alternatives, with susceptibility to abrasion and water damage.

Impact on Application: Silk’s natural properties suit high-end evening wear or glamour pieces inspired by Hollywood styles of the 1930s. However, it is less suitable for everyday wear or harsh climates where durability and easy maintenance are priorities.

Considerations for International Buyers: Buyers in regions with high humidity (e.g., parts of South America, Indonesia) should ensure proper storage and handling to prevent mildew. Compliance with international textile standards such as OEKO-TEX and REACH is common in Europe and increasingly demanded globally. Silk sourcing from ethical and sustainable producers is a growing concern, especially for buyers in Europe and the Middle East focusing on corporate social responsibility.

Rayon (Viscose)

Key Properties: Rayon is a semi-synthetic fiber made from regenerated cellulose, offering a silk-like appearance with good drape and softness. It has moderate moisture absorbency but is prone to shrinkage and loses strength when wet. Rayon is flammable and less resistant to abrasion.

Pros & Cons: Rayon was widely used in the 1930s as a cost-effective alternative to silk, enabling mass production of stylish dresses. It is more affordable and easier to dye than silk but less durable and requires gentle care. Manufacturing complexity is moderate, with environmental concerns around chemical processing.

Impact on Application: Rayon suits mid-range fashion lines replicating 1930s styles, especially for daywear and casual dresses. It balances aesthetics and cost but may not withstand heavy wear or tropical climates without special finishes.

Considerations for International Buyers: Buyers from Africa and South America should consider climate impacts—high humidity and heat can degrade rayon fabrics faster. Compliance with environmental regulations such as EU REACH and US CPSIA for chemical safety is important for export markets. Preference for sustainable viscose variants (e.g., Lenzing Viscose) is growing in Europe and the Middle East.

Wool Crepe

Key Properties: Wool crepe is a textured wool fabric with a crinkled surface, offering excellent wrinkle resistance, moderate elasticity, and good thermal insulation. It is durable, breathable, and resistant to moderate moisture but can be heavy.

Pros & Cons: Wool crepe was popular in 1930s daywear and suits due to its structured appearance and durability. It holds pleats and shapes well, suitable for tailored garments with puff sleeves and fitted waists. However, it is heavier and more expensive than cotton or rayon, and requires careful laundering.

Impact on Application: Ideal for cooler climates or transitional seasons, wool crepe supports the tailored, modest silhouettes of 1930s fashion. It is less suitable for hot, humid regions unless blended with lighter fibers.

Considerations for International Buyers: European buyers, especially in Spain and northern regions, value wool crepe for authenticity and durability. In Africa and the Middle East, wool garments may require blends or lighter weights to suit climate. Compliance with wool grading standards (e.g., IWTO) and labeling regulations is critical for international trade.

Cotton (Including Cotton Crepe and Voile)

Key Properties: Cotton is a natural cellulose fiber known for breathability, moisture absorbency, and ease of dyeing. Cotton crepe and voile variants offer textured or lightweight finishes with good drape. Cotton is durable but prone to wrinkling and can shrink.

Pros & Cons: Cotton was the backbone of affordable 1930s day dresses and casual wear, favored for comfort and practicality. It is cost-effective, easy to manufacture, and widely available globally. However, cotton can fade, wrinkle easily, and lacks the luxurious sheen of silk or rayon.

Impact on Application: Cotton fabrics are suitable for everyday 1930s-inspired dresses, especially in warm climates like Africa and South America. They support mass production and are easy to maintain, aligning with the economic realities of the 1930s.

Considerations for International Buyers: Cotton sourcing is globally widespread, but buyers should ensure compliance with standards like GOTS for organic cotton or Better Cotton Initiative (BCI) for sustainability. In tropical regions, lightweight cotton voile is preferred, while Europe may demand higher thread counts and finishing quality. Importers should verify compliance with ASTM or ISO textile standards depending on the target market.

| Material | Typical Use Case for 1930s dress | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Silk | High-end evening gowns, bias-cut dresses | Luxurious sheen and drape, iconic 1930s glamour | Delicate, expensive, requires careful handling | High |

| Rayon (Viscose) | Mid-range daywear and casual dresses | Affordable silk alternative with good drape | Less durable, sensitive to moisture, environmental concerns | Medium |

| Wool Crepe | Tailored daywear, suits, cooler climate dresses | Durable, wrinkle-resistant, structured silhouette | Heavy, less suitable for hot climates, higher cost | Medium to High |

| Cotton (Crepe, Voile) | Everyday dresses, casual wear, warm climate apparel | Breathable, cost-effective, easy to produce | Prone to wrinkling, less luxurious appearance | Low to Medium |

In-depth Look: Manufacturing Processes and Quality Assurance for 1930s dress

The manufacturing of authentic 1930s-style dresses requires a blend of traditional craftsmanship and modern quality assurance processes to ensure both aesthetic fidelity and product reliability. For international B2B buyers—especially from regions such as Africa, South America, the Middle East, and Europe—understanding these manufacturing stages and quality control (QC) protocols is essential for sourcing high-quality garments that meet global standards.

Manufacturing Process for 1930s Dresses

The production of 1930s dresses typically involves four critical stages: material preparation, forming, assembly, and finishing. Each stage incorporates specific techniques that reflect the era’s distinct style while aligning with contemporary manufacturing efficiencies.

1. Material Preparation

- Fabric Selection: The 1930s favored fabrics like silk, satin, crepe, and textured cotton blends. For bias-cut gowns, silk charmeuse or satin is often chosen due to their fluid drape and sheen.

- Inspection & Cutting: Fabrics undergo incoming quality control (IQC) to verify color consistency, texture, and defect-free material. Cutting is often done on the bias (45-degree angle to grain) for gowns to achieve the era’s signature fluid silhouette.

- Pre-treatment: Some fabrics require washing, stretching, or steaming before cutting to prevent shrinkage and ensure accurate fitting.

2. Forming

- Pattern Making: Precise patterns that replicate 1930s silhouettes—such as nipped-in waists, puffed sleeves, and long hemlines—are drafted, often using CAD software for accuracy.

- Cutting Techniques: Manual or automated cutting aligns with the bias-cut method for gowns or tailored cuts for day dresses and suits.

- Shaping: Some elements, like shoulder pads or corsetry inserts, are formed using foam or fabric layers, integral to achieving the decade’s structured look.

3. Assembly

- Sewing: Skilled stitching is crucial, particularly for delicate bias-cut fabrics which require minimal seams to maintain fluidity. Seams are often finished with French seams or binding to prevent fraying.

- Detailing: Assembly includes adding period-accurate features such as puff sleeves, ruffles, pleats, and covered buttons. This stage may incorporate hand-sewing for intricate details or embellishments.

- Incorporating Fasteners: Zippers, which became popular in the 1930s, are integrated with care to maintain garment aesthetics and functionality.

4. Finishing

- Pressing and Steaming: Garments are pressed with specialized equipment to set creases and shapes, vital for the polished 1930s look.

- Final Inspection: Each piece undergoes a thorough quality check to ensure seam integrity, correct sizing, and flawless finishes.

- Packaging: Dresses are carefully folded or hung with protective covers to maintain shape during transit.

Quality Assurance & Control Framework

Robust quality assurance systems are indispensable for B2B buyers to guarantee the consistent quality of 1930s dresses sourced internationally.

Relevant International Standards

- ISO 9001: This global quality management standard ensures that suppliers implement systematic processes for continuous improvement, risk management, and customer satisfaction.

- Industry-Specific Standards: While fashion garments do not typically require certifications like CE or API, compliance with OEKO-TEX Standard 100 (for textiles free from harmful substances) is increasingly demanded, particularly by buyers in Europe and the Middle East.

- Sustainability Certifications: Certifications such as GOTS (Global Organic Textile Standard) may be relevant for buyers prioritizing eco-friendly sourcing.

Quality Control Checkpoints

- Incoming Quality Control (IQC): Verification of raw materials and fabric rolls for defects, colorfastness, and composition before production starts.

- In-Process Quality Control (IPQC): Continuous monitoring during assembly to ensure stitching quality, correct application of design elements, and dimensional accuracy.

- Final Quality Control (FQC): Comprehensive end-of-line inspection focusing on overall garment appearance, measurements, seam strength, fastener functionality, and packaging quality.

Common Testing Methods

- Fabric Tests: Include tensile strength, pilling resistance, colorfastness to washing and light, and shrinkage tests.

- Garment Tests: Seam strength testing, button/zipper durability, and fit assessment through sample fittings.

- Chemical Tests: Screening for prohibited substances or allergens, increasingly important for international markets with strict import regulations.

Verifying Supplier Quality: Best Practices for B2B Buyers

For buyers across Africa, South America, the Middle East, and Europe, ensuring supplier quality requires proactive engagement and verification strategies.

- On-site Audits: Conduct or commission factory audits to assess production processes, working conditions, and compliance with quality standards. Audits may be scheduled regularly or as pre-shipment checks.

- Third-Party Inspections: Utilize independent inspection agencies to perform IQC, IPQC, and FQC verifications, providing unbiased quality reports and certifications.

- Supplier Quality Documentation: Require comprehensive quality manuals, process flowcharts, and inspection reports to ensure transparency.

- Sample Approval: Approve pre-production and production samples, focusing on fabric authenticity, cut accuracy, and finishing details.

- Digital Traceability: Some suppliers offer digital platforms tracking batch quality data, which can be especially beneficial for buyers managing multiple suppliers internationally.

Quality Control Nuances for International Buyers

- Cultural and Regional Variations: Manufacturing facilities in different regions may interpret quality standards differently. Buyers from Europe or the Middle East should explicitly communicate expectations regarding fabric hand-feel, stitching uniformity, and garment finishing.

- Logistics Impact: Garments shipped to Africa or South America often endure longer transit times and variable climates. Insist on robust packaging and pre-shipment quality checks to minimize damage risks.

- Regulatory Compliance: Ensure suppliers understand and comply with import regulations specific to your region, including labeling requirements, chemical restrictions, and product safety standards.

- Language and Communication: Clear, documented quality agreements help bridge language barriers common in global sourcing. Visual aids such as photos and videos of quality standards can improve mutual understanding.

- Sustainability and Ethical Standards: Buyers in Europe and parts of the Middle East increasingly prioritize sustainable sourcing and ethical labor practices. Incorporate these criteria into your supplier evaluation and QC checklist.

Summary for B2B Buyers

When sourcing 1930s dresses internationally, a thorough grasp of manufacturing processes and quality assurance protocols is vital. The combination of traditional techniques—like bias cutting and hand detailing—with modern QC systems ensures garments that are both authentic and reliable. By leveraging international standards (ISO 9001, OEKO-TEX), implementing stringent QC checkpoints, and engaging in diligent supplier verification, buyers from diverse regions can confidently procure high-quality 1930s fashion that meets their market’s demands.

This strategic approach mitigates risks related to inconsistent quality, regulatory non-compliance, and logistics challenges, ultimately enhancing buyer confidence and customer satisfaction in global B2B fashion trade.

Related Video: Garments Full Production Process | Order receive to Ex-Factory | Episode 2

Comprehensive Cost and Pricing Analysis for 1930s dress Sourcing

Sourcing 1930s-style dresses involves a multifaceted cost structure influenced by both tangible production elements and strategic pricing considerations. Understanding these components empowers international B2B buyers—especially those from Africa, South America, the Middle East, and Europe—to negotiate effectively and optimize procurement.

Key Cost Components in 1930s Dress Production

-

Materials: The choice of fabric is paramount. Authentic 1930s dresses often utilize silk, satin, crepe, and textured cottons, each varying significantly in cost. Silk and satin bias-cut gowns demand higher-quality raw materials, elevating base costs, while cotton or blended fabrics offer more economical options.

-

Labor: Skilled craftsmanship is critical, especially for intricate bias-cut techniques and detailed tailoring like puff sleeves, shoulder pads, or pleats. Labor costs fluctuate by region, with manufacturers in Asia or Eastern Europe often offering competitive rates compared to Western Europe or North America.

-

Manufacturing Overhead: This includes factory utilities, equipment maintenance, and indirect labor. Factories specializing in vintage or period fashion may have higher overhead due to specialized machinery or manual processes required for authenticity.

-

Tooling and Development: Initial pattern making, sample creation, and adjustments for fit and style add upfront costs. For custom or limited-run 1930s designs, tooling expenses are proportionally higher.

-

Quality Control (QC): Given the delicate fabrics and detailed construction, rigorous QC is essential to ensure consistency and reduce returns. QC costs encompass inspection labor and potential reworks.

-

Logistics: International shipping, customs duties, insurance, and handling fees impact landed costs. Sourcing from Asia or Europe entails varying freight costs, with air freight preferred for speed but sea freight offering better economies for bulk orders.

-

Margin: Suppliers include profit margins, typically ranging from 10% to 30%, depending on exclusivity, brand positioning, and order volume.

Influencing Factors on Pricing

-

Order Volume and Minimum Order Quantity (MOQ): Larger volumes typically reduce per-unit cost due to economies of scale. Many manufacturers set MOQs that influence pricing tiers; buyers should balance order size with inventory capacity.

-

Design Specifications and Customization: Complex details like bias cuts, hand-finishing, or unique embellishments increase costs. Simple, factory-produced styles are cheaper but may lack authentic 1930s flair.

-

Material Quality and Certifications: Premium or certified fabrics (e.g., organic cotton, sustainably sourced silk) command higher prices but can open access to eco-conscious markets.

-

Supplier Location and Reputation: Established suppliers with proven track records in vintage apparel may charge premiums but offer reliability and quality assurances.

-

Incoterms: The chosen shipping terms (FOB, CIF, DDP, etc.) affect cost allocation between buyer and supplier. Buyers should clarify responsibilities for shipping, insurance, and customs clearance to avoid unexpected expenses.

Strategic Buyer Tips for International B2B Procurement

-

Negotiation Levers: Emphasize volume commitments, repeat orders, and flexible delivery schedules to negotiate better pricing. Consider bundling orders with complementary products (e.g., vintage accessories) for supplier discounts.

-

Cost-Efficiency Measures: Evaluate fabric substitutions or blended materials that maintain vintage aesthetics but reduce costs. Collaborate with suppliers to optimize construction methods without compromising style.

-

Total Cost of Ownership (TCO): Beyond unit price, factor in shipping times, customs tariffs, currency fluctuations, and potential delays. For buyers in Africa and South America, longer transit times and port inefficiencies can increase TCO, making local or regional sourcing worth exploring.

-

Understanding Pricing Nuances: European buyers, such as those in Spain, may face higher VAT and labor-related costs, while Middle Eastern buyers should consider import regulations and cultural fit for styles. Indonesian buyers might leverage proximity to Southeast Asian textile hubs for cost savings.

-

Quality vs. Price Balance: Prioritize suppliers offering robust QC processes to minimize returns and brand reputation risks. Authentic 1930s dress details often justify a premium, especially for niche or luxury markets.

Indicative Pricing Disclaimer

Prices for 1930s dresses vary widely depending on fabric quality, design complexity, and sourcing region. Indicative wholesale prices can range from approximately USD 25–100 per piece for mass-produced cotton or polyester blends, up to USD 150–400 or more for authentic silk bias-cut gowns with intricate detailing. Buyers should request detailed quotations tailored to their specifications and order volumes.

By dissecting cost drivers and pricing influencers, international B2B buyers can better strategize sourcing, negotiate favorable terms, and ensure a competitive edge in marketing authentic 1930s fashion in their respective markets.

Spotlight on Potential 1930s dress Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘1930s dress’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for 1930s dress

Key Technical Properties of 1930s Dresses for B2B Buyers

Understanding the technical specifications of 1930s-style dresses is essential for international buyers aiming to source authentic or inspired garments that meet quality and market expectations. Here are the critical properties to consider:

-

Fabric Composition and Grade

The 1930s favored natural fibers such as silk, satin, crepe, and cotton, often with a bias-cut to enhance drape and fit. Fabric grade impacts durability, sheen, and feel. For example, high-grade silk satin offers smoothness and luster ideal for evening gowns, while cotton crepe suits daywear. Buyers should specify fiber content and quality grades to ensure fabric authenticity and performance. -

Cut and Silhouette Accuracy

The defining feature of 1930s dresses is the bias cut, which requires precise 45-degree diagonal fabric cutting. This technique allows garments to stretch and contour the body elegantly. Suppliers must demonstrate expertise in bias-cutting to achieve the characteristic fluidity and fit without distortion. Accurate replication of fitted waists, puff sleeves, and midi-to-floor length hemlines is also critical for authenticity. -

Color Fastness and Dye Quality

Given the era’s palette ranged from subtle pastels to the iconic “shocking pink,” color fastness is vital. Buyers should request dye test reports to confirm resistance to fading, especially for vibrant or dark hues. This ensures garments maintain their visual appeal through handling, shipping, and end use in diverse climates. -

Seam and Stitching Tolerances

Precision in stitching affects both garment durability and aesthetic. Typical seam allowances for 1930s dresses range from 1 to 1.5 cm, with reinforced stitching on stress points such as waist darts and shoulder pads. Buyers should specify tolerance levels—±2 mm is standard for high-quality vintage reproductions—to guarantee consistent sizing and finish. -

Accessory Integration

Many 1930s dresses incorporate period-specific elements such as shoulder pads, belts, and decorative buttons. The technical specification should include details on accessory materials, attachment methods (e.g., sewn-in vs. removable), and compatibility with the garment to maintain design integrity and ease of wear. -

Packaging and Labeling Compliance

For international trade, packaging must protect delicate fabrics and maintain shape (e.g., tissue wrapping, garment bags). Labels should reflect fiber content, country of origin, care instructions, and size in accordance with local regulations. Buyers should clarify these requirements upfront to avoid customs delays and ensure retail readiness.

Essential Trade Terminology for International 1930s Dress Buyers

Navigating international apparel sourcing requires familiarity with key trade terms that affect negotiations, logistics, and contract clarity:

-

OEM (Original Equipment Manufacturer)

Refers to suppliers who produce garments based on the buyer’s designs and specifications. For 1930s dress sourcing, OEMs can manufacture custom vintage-style collections tailored to market needs, offering control over fabric, cut, and embellishments. -

MOQ (Minimum Order Quantity)

The smallest order volume a supplier will accept. MOQs for 1930s dresses can vary widely depending on fabric costs and production complexity. Buyers from emerging markets should negotiate MOQs balancing cost efficiency with inventory risk. -

RFQ (Request for Quotation)

A formal inquiry sent to suppliers detailing product specifications, quantities, and delivery timelines to obtain pricing and terms. Precise RFQs for 1930s dresses should include technical property requirements to ensure comparable bids. -

Incoterms (International Commercial Terms)

Standardized trade terms defining responsibilities for shipping, insurance, and customs. Common terms include FOB (Free on Board) and CIF (Cost, Insurance, Freight). Understanding Incoterms helps buyers from Africa, South America, the Middle East, and Europe manage costs and risks effectively. -

Lead Time

The total time from order placement to delivery. For historically accurate 1930s dresses, lead times may be longer due to fabric sourcing and skilled craftsmanship. Buyers should factor this into production schedules and market launches. -

Tech Pack

A detailed document including drawings, measurements, fabric specs, and construction notes. Supplying a comprehensive tech pack for 1930s dress designs minimizes errors and ensures consistent production quality across batches and suppliers.

By mastering these technical properties and trade terms, international B2B buyers can confidently source authentic and high-quality 1930s dresses that meet diverse market demands while optimizing supply chain efficiency.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the 1930s dress Sector

Market Overview & Key Trends

The global market for 1930s-inspired dresses is experiencing a resurgence driven by nostalgia, vintage fashion appreciation, and sustainable consumerism. International B2B buyers from Africa, South America, the Middle East, and Europe are increasingly tapping into this niche to diversify their offerings and cater to a discerning clientele interested in unique, timeless styles. Key market drivers include growing interest in heritage fashion aesthetics, the influence of classic Hollywood glamour, and the rise of retro-themed events and fashion subcultures.

From a sourcing perspective, the demand for authentic or well-crafted replica 1930s dresses has spurred innovation in textile production and garment manufacturing. Bias-cut gowns, signature to the 1930s, require skilled craftsmanship and premium fabrics such as silk and satin, which are often sourced from specialized suppliers. Buyers from regions like Spain and Indonesia are leveraging local textile expertise combined with global supply chains to balance authenticity and cost efficiency.

Illustrative Image (Source: Google Search)

Technological advancements are shaping the sector as well. Digital platforms facilitate direct communication between designers, manufacturers, and buyers, enabling customization and small batch production that aligns with the vintage market’s exclusivity. Additionally, 3D garment visualization and virtual sampling reduce lead times and costs, helping international buyers evaluate quality and fit before committing to orders.

The market also exhibits dynamic pricing influenced by fabric quality, detailing complexity, and brand heritage. Buyers must navigate these variables while considering regional preferences—for example, African markets may prioritize vibrant prints and durability, whereas European buyers might seek high-end finishes and historical accuracy. Overall, agility in sourcing, combined with strong supplier relationships and market insight, is critical for success in this sector.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a pivotal factor in the 1930s dress sector, reflecting broader global trends toward environmentally responsible fashion. The original 1930s dresses were often created during an era marked by economic hardship, leading to a focus on durability and practicality—principles that resonate well with today’s sustainable sourcing ethos.

For B2B buyers, ethical supply chains are essential to uphold brand reputation and meet increasingly stringent regulatory and consumer demands. This includes ensuring fair labor practices, transparency in manufacturing processes, and minimizing environmental impact throughout the product lifecycle. Buyers sourcing from regions with developing textile industries should prioritize suppliers certified by recognized standards such as GOTS (Global Organic Textile Standard) or OEKO-TEX, which verify organic materials and non-toxic production.

Material selection is another critical component. Sustainable fabrics like organic cotton, bamboo, or recycled silk blends offer eco-friendly alternatives without compromising the luxurious feel necessary for 1930s-inspired designs. Moreover, sourcing deadstock or upcycled vintage fabrics aligns with circular economy principles, reducing waste and adding authentic vintage character.

Implementing sustainability also means optimizing supply chain logistics to reduce carbon footprints. Consolidated shipments, local sourcing where possible, and investing in renewable energy-powered production facilities can contribute to greener operations. Ultimately, B2B buyers who embed sustainability into their sourcing strategy not only address environmental concerns but also unlock competitive advantages in a market increasingly driven by conscious consumers.

Brief Evolution and Historical Context

The 1930s dress sector is deeply rooted in a decade of transformation shaped by social, economic, and cultural forces. Following the exuberance of the 1920s, 1930s fashion embraced sophistication and practicality as a response to the Great Depression’s hardships. This period saw the rise of longer hemlines, fitted waistlines, and the innovative bias-cut technique pioneered by designers like Madeleine Vionnet, which created elegant, body-flattering silhouettes.

Hollywood’s golden age played a crucial role in popularizing glamorous evening gowns and satin slip dresses, making film stars such as Jean Harlow and Greta Garbo influential style icons. Meanwhile, designers like Elsa Schiaparelli introduced surrealism and bold colors, expanding the creative boundaries of the era’s fashion.

For B2B buyers, understanding this historical evolution is vital for sourcing authentic or inspired pieces that resonate with contemporary consumers. The 1930s dress remains a symbol of resilience, artistry, and timeless elegance—qualities that continue to appeal across global markets today.

Related Video: The Silk Road: Connecting the ancient world through trade – Shannon Harris Castelo

Frequently Asked Questions (FAQs) for B2B Buyers of 1930s dress

-

How can I effectively vet suppliers of 1930s dresses to ensure authenticity and quality?

Start by requesting detailed product portfolios showcasing past work, including high-resolution images and fabric samples. Verify supplier credentials through certifications such as ISO standards or industry-specific quality marks. Check references and customer reviews, especially from similar international markets. Conduct virtual or on-site factory audits if possible. Emphasize suppliers experienced in vintage or period-specific apparel, as these require unique craftsmanship. A thorough vetting process minimizes risks of receiving substandard or inauthentic 1930s dresses. -

Is customization available for 1930s dresses, and what are typical options?

Yes, many suppliers offer customization to meet market-specific demands. Common customizations include fabric selection (silk, satin, crepe), color variations (e.g., “shocking pink” inspired by Elsa Schiaparelli), sizing adjustments, and embellishments like ruffles or shoulder pads. Buyers can also request modifications to dress cuts—such as bias-cut gowns or midi-length skirts—to align with local consumer preferences. Early communication of design requirements ensures smoother production and adherence to vintage authenticity. -

What are the usual minimum order quantities (MOQs) and lead times when sourcing 1930s dresses internationally?

MOQs typically range from 50 to 200 units per style, depending on supplier capacity and customization level. Lead times vary from 6 to 12 weeks, factoring in fabric sourcing, tailoring complexity, and quality checks. Bulk orders often yield better pricing but require longer planning. For buyers in Africa, South America, the Middle East, and Europe, it’s advisable to plan orders well in advance and confirm production schedules to accommodate shipping and customs clearance. -

Which payment methods are safest and most common for international B2B transactions in vintage fashion sourcing?

Common payment methods include Letters of Credit (L/C), Telegraphic Transfers (T/T), and escrow services. Letters of Credit provide strong protection by tying payment to verified shipment documents, ideal for larger orders. T/T payments require trust and are often split into deposits and balance payments upon delivery. Escrow platforms offer neutral third-party oversight, reducing risks in new supplier relationships. Negotiating clear payment terms aligned with production milestones is critical for cash flow management. -

What quality assurance (QA) practices and certifications should I expect from reputable 1930s dress manufacturers?

Reputable manufacturers implement multi-stage QA processes, including fabric inspection, in-process stitching checks, and final product evaluation for fit and finish. Certifications such as ISO 9001 (Quality Management Systems) and Oeko-Tex Standard 100 (textile safety) are indicators of quality and compliance with international standards. For vintage-inspired garments, adherence to historical accuracy in design and materials is also a quality marker. Requesting QA reports and sample approvals before bulk production helps maintain standards. -

How should I manage logistics and shipping for 1930s dresses to minimize delays and costs?

Coordinate with suppliers to consolidate shipments and choose the most suitable shipping method—sea freight for cost efficiency on large orders or air freight for faster delivery of samples or smaller quantities. Engage experienced freight forwarders familiar with your region’s customs regulations, especially for Africa and the Middle East where clearance can be complex. Ensure all documentation, including invoices, packing lists, and certificates of origin, is accurate to avoid customs delays. Consider insurance to protect against transit risks. -

What strategies can help resolve disputes with suppliers over product quality or delivery issues?

Establish clear contracts detailing product specifications, delivery timelines, payment terms, and dispute resolution mechanisms before placing orders. In case of disputes, initiate direct communication to understand issues and negotiate remedies like partial refunds, replacements, or discounts. Employ third-party inspection services to provide unbiased quality assessments. If unresolved, leverage mediation or arbitration clauses included in contracts. Maintaining professional relationships while protecting your interests is key to long-term success.

- Are there specific considerations for B2B buyers from diverse regions like Africa, South America, the Middle East, and Europe when sourcing 1930s dresses?

Yes, regional market preferences and regulatory environments vary significantly. African and South American buyers might prioritize durability and fabric suitability for tropical climates, favoring breathable cotton blends. Middle Eastern markets often seek modest yet glamorous designs aligned with cultural norms. European buyers, such as from Spain or Indonesia, may focus on historical accuracy and luxury fabrics for boutique retail. Understanding local consumer behavior, import duties, and compliance requirements ensures smoother market entry and customer satisfaction.

Strategic Sourcing Conclusion and Outlook for 1930s dress

Strategic sourcing of 1930s dresses presents a unique opportunity for international B2B buyers to blend historical elegance with contemporary market demands. The decade’s hallmark features—bias-cut gowns, tailored silhouettes, and distinctive accessories—offer rich potential for differentiation in diverse markets across Africa, South America, the Middle East, and Europe. Buyers should prioritize suppliers who demonstrate expertise in authentic vintage techniques alongside scalable production capabilities, ensuring quality and cost-efficiency.

Key takeaways for B2B buyers include:

- Supplier Selection: Focus on manufacturers skilled in bias-cut tailoring and period-accurate detailing to preserve the distinctive 1930s aesthetic.

- Material Sourcing: Prioritize suppliers offering sustainable silk, satin, and textured fabrics that reflect the era’s fabric innovation while meeting modern sustainability standards.

- Market Adaptation: Leverage regional consumer preferences by integrating culturally relevant design elements without compromising the classic 1930s style.

- Cost Management: Utilize economies of scale through consolidated orders and long-term partnerships to optimize pricing in competitive global markets.

Looking ahead, the fusion of vintage glamour with modern production technologies positions 1930s dresses as a compelling niche in the fashion industry. International buyers are encouraged to engage proactively with specialized suppliers and explore collaborative design innovations that resonate with evolving global tastes. Embracing strategic sourcing today will unlock new growth avenues and reinforce market leadership in the heritage-inspired apparel sector.