Definitive Guide to Sourcing High-Quality Applique Dresses

Guide to Applique Dress

- Introduction: Navigating the Global Market for applique dress

- Understanding applique dress Types and Variations

- Key Industrial Applications of applique dress

- Strategic Material Selection Guide for applique dress

- In-depth Look: Manufacturing Processes and Quality Assurance for applique dress

- Comprehensive Cost and Pricing Analysis for applique dress Sourcing

- Spotlight on Potential applique dress Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for applique dress

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the applique dress Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of applique dress

- Strategic Sourcing Conclusion and Outlook for applique dress

Introduction: Navigating the Global Market for applique dress

The global market for applique dresses presents a vibrant opportunity for international B2B buyers seeking to diversify their product offerings with distinctive, high-value garments. Applique dresses—characterized by their intricate fabric overlays and artistic embellishments—combine craftsmanship with fashion-forward appeal, making them a coveted category in markets across Africa, South America, the Middle East, and Europe. For buyers in regions such as Spain and Brazil, sourcing applique dresses means tapping into a blend of cultural aesthetics and contemporary trends that resonate strongly with discerning consumers.

Successfully navigating this sector requires a deep understanding of the entire supply chain—from fabric selection and applique techniques to manufacturing standards and quality control protocols. This guide delivers a comprehensive roadmap tailored to the needs of international buyers, covering essential aspects including:

- Diverse types and styles of applique dresses suited to various market preferences

- Key materials and sustainable fabric options that balance quality and cost-effectiveness

- Advanced manufacturing processes and rigorous quality assurance measures

- Strategies for identifying reliable suppliers with ethical production practices

- Transparent cost structures and pricing considerations for optimized sourcing

- Market insights highlighting regional demand patterns and emerging trends

- Answers to frequently asked questions that clarify common sourcing challenges

Equipped with this knowledge, B2B buyers can make informed, strategic decisions that minimize risks and maximize return on investment. By leveraging expert insights and actionable guidance, international buyers will be empowered to source applique dresses that align with their brand values, satisfy their customers’ expectations, and thrive in a competitive global marketplace.

Understanding applique dress Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Hand-Appliquéd Dresses | Intricate, manually sewn appliqué designs; high artisan involvement | Premium fashion collections, luxury boutiques | High uniqueness and craftsmanship; higher cost and longer lead times |

| Machine-Appliquéd Dresses | Appliqué applied via automated sewing machines; consistent patterns | Mass-market apparel, fast fashion brands | Cost-effective and scalable; less intricate detail than handwork |

| 3D Appliqué Dresses | Appliqué with raised, textured elements using layering or padding | High-end event wear, designer collaborations | Visually striking and tactile; requires skilled manufacturing, higher MOQ |

| Laser-Cut Appliqué Dresses | Appliqué pieces precisely cut by laser for sharp edges and complex shapes | Innovative fashion lines, tech-savvy brands | Modern aesthetic and precision; investment in tech and design adaptation needed |

| Mixed-Media Appliqué Dresses | Combines fabrics, embroidery, beads, and other embellishments | Couture, theatrical costumes, special occasions | Highly customizable and unique; complex sourcing and production process |

Hand-Appliquéd Dresses

These dresses feature appliqué designs sewn by skilled artisans, offering exceptional detail and uniqueness. Ideal for luxury and boutique markets in regions valuing craftsmanship such as Europe and the Middle East, hand-appliquéd dresses appeal to customers seeking exclusivity. For B2B buyers, this type demands higher investment and longer production cycles but yields premium pricing potential. Careful partner selection with expertise in artisan work is critical to maintaining quality and authenticity.

Machine-Appliquéd Dresses

Utilizing automated sewing machines, these dresses allow for faster production with consistent appliqué patterns. They are suited for large-scale manufacturers targeting mass-market consumers in South America and Africa, where cost efficiency and volume are priorities. Buyers benefit from reduced unit costs and quicker turnaround but should anticipate less intricate designs compared to handwork. Verifying machine capabilities and quality control processes is essential for reliable supply.

3D Appliqué Dresses

This variation incorporates raised or layered appliqué elements, creating textured and visually impactful garments. Popular in high-end event wear and designer collaborations, 3D appliqué resonates well in markets like Europe and the Middle East, where innovation and exclusivity are prized. B2B buyers should consider the technical skills required and potential higher minimum order quantities. Selecting manufacturers experienced in 3D textile manipulation ensures the final product meets aesthetic expectations.

Laser-Cut Appliqué Dresses

Laser-cut appliqué uses advanced technology to create precise, sharp-edged appliqué pieces, enabling complex and modern designs. This type is attractive to innovative fashion lines and brands emphasizing technology-driven aesthetics, especially in European and South American markets. For B2B buyers, investment in design adaptation and partnering with manufacturers equipped with laser-cutting technology is crucial. The approach offers scalability with design precision but may require upfront development time.

Mixed-Media Appliqué Dresses

Combining various materials such as fabrics, embroidery, beads, and sequins, mixed-media appliqué dresses offer highly customizable and unique looks. This type suits couture, theatrical costumes, and special occasion apparel favored in diverse international markets including Africa and the Middle East. Buyers should be prepared for complex sourcing and longer production timelines due to the variety of materials and techniques involved. Collaborating with versatile manufacturers capable of handling multiple embellishment types is key to success.

Related Video: A Practical Introduction to Large Language Models (LLMs)

Key Industrial Applications of applique dress

| Industry/Sector | Specific Application of Applique Dress | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion Retail & Boutiques | Premium seasonal collections and limited editions | Differentiation through unique, artisanal garment appeal | High-quality fabric base, skilled applique craftsmanship, MOQ flexibility |

| Event & Bridal Wear | Wedding gowns, evening wear, and ceremonial dresses | Adds intricate detailing, enhancing exclusivity and luxury | Customization options, sustainable materials, and timely delivery |

| Cultural & Traditional Garments | Ethnic and heritage-inspired dresses with applique motifs | Preserves cultural identity while appealing to global markets | Authentic design expertise, ethical sourcing, and fabric durability |

| Luxury Hospitality & Tourism | Uniforms and guest apparel for high-end hotels/resorts | Elevates brand image through bespoke, elegant attire | Consistent quality, comfortable fabrics, and scalable production |

| Export & Wholesale Distribution | Bulk supply to multi-regional fashion chains | Cost-effective production with consistent quality control | Compliance with international trade regulations, packaging, and logistics |

Applique dresses find extensive application in the Fashion Retail & Boutiques sector, particularly for premium seasonal collections and limited edition lines. These dresses leverage detailed applique work to create standout pieces that appeal to discerning customers in markets like Spain, Brazil, and the Middle East. For B2B buyers, sourcing requires close collaboration with manufacturers who offer flexibility in minimum order quantities (MOQs) and ensure high craftsmanship standards. This enables retailers to maintain exclusivity while managing inventory risks effectively.

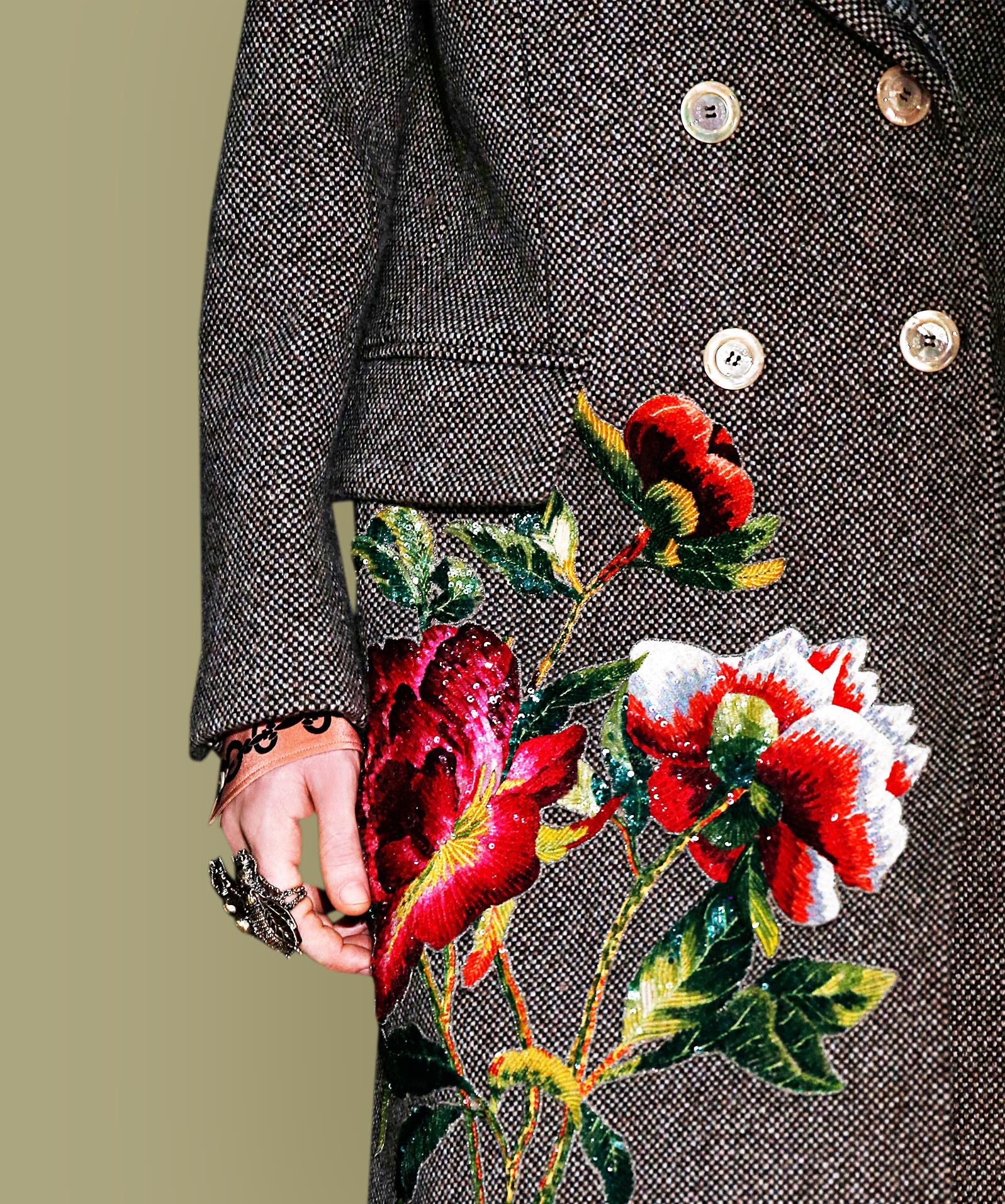

Illustrative Image (Source: Google Search)

In the Event & Bridal Wear industry, applique dresses are pivotal for creating luxurious wedding gowns and ceremonial attire. The intricate applique patterns add a distinct texture and visual richness, highly valued in upscale markets across Europe and Africa. Buyers must prioritize suppliers capable of customization and who use sustainable, high-quality fabrics to meet the growing demand for eco-conscious luxury. Timely delivery aligned with event schedules is crucial to maintain client satisfaction.

The Cultural & Traditional Garments sector benefits greatly from applique dresses that incorporate ethnic motifs and heritage-inspired designs. This application is especially significant in regions like South America and Africa, where preserving cultural identity through fashion is both a commercial and social imperative. B2B buyers should seek partners with authentic design expertise and ethical sourcing practices to ensure garments resonate with both local and international consumers, while also maintaining durability for repeated use.

In Luxury Hospitality & Tourism, applique dresses serve as uniforms or guest apparel that reinforce a brand’s image of exclusivity and sophistication. High-end hotels and resorts across the Middle East and Europe often require elegant, comfortable garments that can be produced at scale without compromising quality. Buyers in this sector need suppliers who can deliver consistent quality, use breathable fabrics suitable for various climates, and handle scalable production runs to meet fluctuating seasonal demands.

For Export & Wholesale Distribution, applique dresses are manufactured in bulk for multi-regional fashion chains targeting diverse markets, including Brazil and Spain. This application emphasizes cost-effectiveness alongside consistent quality control to ensure brand standards across different geographies. International B2B buyers must carefully evaluate suppliers’ compliance with trade regulations, packaging standards, and logistics capabilities to avoid delays and additional costs during cross-border shipments.

Related Video: Uses of Metals and Non Metals

Strategic Material Selection Guide for applique dress

When selecting materials for applique dresses, international B2B buyers must consider factors such as fabric durability, aesthetic appeal, manufacturing complexity, and regional market preferences. The material choice directly influences the garment’s quality, cost, and end-user satisfaction. Below is an analysis of four common materials used in applique dresses, focusing on their key properties, advantages, limitations, and regional considerations.

Cotton Fabric

Key Properties:

Cotton is a natural fiber known for its breathability, softness, and moisture absorption. It handles moderate temperature ranges well but is prone to shrinkage and wrinkles. Cotton is compatible with most applique adhesives and sewing techniques without special treatment.

Pros & Cons:

Cotton is highly durable and comfortable, making it ideal for everyday wear. It is relatively affordable and widely available, simplifying sourcing. However, cotton can be heavier than synthetic alternatives and may fade or wear out faster if not treated properly.

Impact on Application:

Cotton’s natural texture provides a strong base for applique work, allowing for secure stitching and good adhesion. It is suitable for casual and semi-formal dresses, especially in warmer climates where breathability is valued.

International B2B Considerations:

Buyers in Africa, South America, and the Middle East often prefer cotton due to its comfort in hot climates. European markets, including Spain, increasingly demand organic or sustainably sourced cotton (e.g., GOTS-certified), which may affect supplier selection and pricing. Compliance with OEKO-TEX or REACH standards is critical for European buyers to ensure chemical safety.

Polyester Fabric

Key Properties:

Polyester is a synthetic fiber known for its high tensile strength, wrinkle resistance, and quick-drying properties. It withstands higher temperatures during manufacturing and resists shrinking and stretching.

Pros & Cons:

Polyester is cost-effective and easy to maintain, with excellent color retention. However, it is less breathable than natural fibers and can feel less comfortable in hot climates. The synthetic nature may pose challenges for buyers focused on sustainability.

Impact on Application:

Polyester’s smooth surface facilitates detailed applique designs and supports digital printing techniques. It is well-suited for mass production due to its uniformity and durability.

International B2B Considerations:

In regions like the Middle East and South America, polyester’s durability and ease of care are attractive for export markets. European buyers may require suppliers to demonstrate compliance with EU regulations on microplastics and chemical use. Buyers should also consider the environmental impact and potential demand for recycled polyester variants.

Linen Fabric

Key Properties:

Linen, derived from flax fibers, offers excellent breathability and moisture-wicking capabilities. It is stronger than cotton but more prone to wrinkles. Linen performs well under moderate temperature and humidity but requires careful handling during applique application due to its coarse texture.

Pros & Cons:

Linen’s natural luster and texture add a premium feel to applique dresses. It is durable and eco-friendly but generally more expensive and less elastic, which can complicate garment construction.

Impact on Application:

Linen is ideal for high-end, casual, or resort wear applique dresses, especially in warm climates. The fabric’s texture can enhance applique aesthetics but may require specialized adhesives or stitching techniques.

International B2B Considerations:

Buyers in Europe, particularly Spain, often favor linen for its sustainability and luxury appeal. African and South American markets may appreciate its breathability but need to balance cost implications. Compliance with European textile labeling and sustainability certifications (e.g., EU Ecolabel) is important.

Tulle (Mesh) Fabric

Key Properties:

Tulle is a lightweight, fine netting fabric typically made from nylon, polyester, or silk. It has high tensile strength relative to its weight but is delicate and prone to snagging. Tulle is heat-sensitive and requires low-temperature handling during applique attachment.

Pros & Cons:

Tulle offers an ethereal, decorative base perfect for intricate applique patterns and overlays. It is lightweight and adds volume without bulk. However, it is less durable for everyday wear and requires careful handling in production and use.

Impact on Application:

Tulle is predominantly used in formal and bridal applique dresses where visual impact is paramount. Its transparency allows for layered applique effects, enhancing design complexity.

International B2B Considerations:

Middle Eastern and European buyers often seek tulle for luxury and ceremonial garments. South American markets may use it for festive wear. Importers should verify compliance with flammability standards (e.g., NFPA in the US, EN standards in Europe) and ensure suppliers provide consistent mesh quality to avoid production defects.

| Material | Typical Use Case for applique dress | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Cotton Fabric | Casual and semi-formal applique dresses | Breathable, comfortable, widely available | Prone to shrinkage and fading | Low |

| Polyester Fabric | Mass-produced, durable applique dresses | Durable, wrinkle-resistant, cost-effective | Less breathable, environmental concerns | Low |

| Linen Fabric | High-end, resort wear applique dresses | Eco-friendly, strong, premium texture | Expensive, wrinkles easily | Medium |

| Tulle Fabric | Formal, bridal, and decorative applique dresses | Lightweight, visually striking | Delicate, requires careful handling | Medium |

This guide equips international buyers with a clear understanding of material options for applique dresses, enabling informed sourcing decisions that align with market demands and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for applique dress

Manufacturing Processes for Applique Dresses

The production of applique dresses involves a series of meticulously coordinated stages, each critical to ensuring the final garment meets high standards of quality and design. For international B2B buyers—especially those in Africa, South America, the Middle East, and Europe—understanding these stages helps in selecting reliable suppliers and optimizing supply chain efficiency.

1. Material Preparation

Material preparation is the foundational step where fabric and applique components are sourced and readied. Common fabrics include cotton blends, chiffon, silk, or polyester, chosen based on the garment’s style and intended market. The applique elements—often lace, embroidered patches, sequins, or other decorative fabrics—are carefully selected for compatibility with the base fabric.

Key considerations in this stage include:

- Supplier reliability: Ensuring fabrics and appliques come from vetted suppliers with certifications (e.g., OEKO-TEX, GOTS for organic fabrics).

- Pre-treatment: Washing, dyeing, or finishing fabric to prevent shrinkage or color bleeding.

- Cutting: Precision cutting of both base fabric and applique pieces using laser or die-cutting machines to achieve intricate designs with minimal waste.

2. Forming and Applique Application

This stage focuses on shaping the dress components and attaching the applique decorations. Techniques vary by design complexity and production scale.

- Hand-sewn applique: Common for high-end or limited-edition dresses, providing detailed craftsmanship but slower throughput.

- Machine embroidery and applique: Automated embroidery machines apply applique patterns with speed and repeatability, ideal for medium to large batches.

- Heat-press and adhesive methods: Used for specific applique types, offering quick application but requiring strict control to maintain durability.

The forming process also includes assembling bodices, skirts, and sleeves to prepare for final garment assembly.

3. Assembly and Sewing

Once applique pieces are applied, garment components are stitched together using industrial sewing machines. This phase demands precision to maintain alignment and integrity of applique work.

- Cut and sew method: Predominantly used for applique dresses due to the need for customization and quality control.

- Seam finishing: Techniques such as serging or binding prevent fraying, essential for maintaining garment longevity.

- Integration of additional features: Zippers, linings, and embellishments are added, ensuring the dress functions well and matches design specifications.

4. Finishing and Quality Enhancement

Finishing includes pressing, trimming loose threads, and final inspections. Additional treatments like steaming or fabric stiffening may be applied to enhance appearance.

- Packaging: Garments are carefully folded or hung, with protective covers to maintain pristine condition during shipping.

- Labeling: Compliance with international labeling standards (fiber content, care instructions) is ensured to meet import regulations in various regions.

Quality Assurance in Applique Dress Manufacturing

Robust quality assurance (QA) is non-negotiable for B2B buyers seeking consistent, high-quality applique dresses. International buyers must consider both global standards and regional compliance requirements.

Relevant International Standards

- ISO 9001: The globally recognized quality management system standard ensures suppliers have systematic processes to maintain product quality and continual improvement.

- OEKO-TEX Standard 100: Certifies textiles free from harmful substances, crucial for markets with strict safety regulations.

- CE Marking: Relevant if applique dresses incorporate elements that fall under EU safety directives, such as certain accessories or components.

- Regional regulations: Buyers in Europe (e.g., Spain) must ensure compliance with REACH regulations on chemical substances, while South American and Middle Eastern markets may have specific import safety standards.

Quality Control Checkpoints

Quality control (QC) in applique dress manufacturing is typically segmented into three main checkpoints:

- Incoming Quality Control (IQC): Inspection of raw materials and applique components upon arrival to verify compliance with specifications and certifications.

- In-Process Quality Control (IPQC): Continuous monitoring during production, focusing on applique attachment integrity, stitching quality, and dimensional accuracy.

- Final Quality Control (FQC): Comprehensive examination of finished garments for defects, color consistency, applique adhesion, and packaging standards.

Common Testing Methods

- Colorfastness testing: Ensures dyes and applique materials do not bleed or fade under washing, rubbing, or light exposure.

- Tensile and seam strength tests: Verify the durability of applique attachments and garment seams.

- Dimensional checks: Confirm garment measurements align with agreed technical packs.

- Visual inspection: Detects any flaws such as loose threads, misaligned applique, or fabric defects.

How B2B Buyers Can Verify Supplier Quality Control

For international buyers, particularly those operating across diverse regions, verifying supplier QC capabilities is critical to mitigating risk and ensuring product consistency.

Supplier Audits and Certifications

- Factory audits: Onsite or virtual audits assessing compliance with ISO 9001, ethical labor practices, and environmental standards.

- Certification verification: Requesting and validating supplier certifications related to quality, sustainability, and safety.

- Technical capability reviews: Evaluating machinery, workforce skills, and production processes specifically for applique work.

Quality Reports and Samples

- Pre-shipment inspection reports: Detailed documentation of QC checks conducted before shipment, often accompanied by photographic evidence.

- Product samples: Testing physical samples prior to bulk orders helps assess workmanship and material quality.

- Third-party inspections: Engaging independent inspection agencies (e.g., SGS, Bureau Veritas) to conduct unbiased QC assessments adds assurance, especially for buyers in Africa, South America, and the Middle East where local oversight may be limited.

QC and Certification Nuances for International Buyers

- Import regulations: Different regions impose varying rules on textile imports, requiring buyers to ensure supplier compliance to avoid customs delays or penalties.

- Sustainability demands: European buyers, including Spain, increasingly prioritize eco-friendly sourcing and production certifications, influencing supplier selection.

- Customization and MOQ flexibility: Buyers from emerging markets may require smaller minimum order quantities and more bespoke applique designs, necessitating suppliers with flexible QC processes.

- Communication and traceability: Transparent QC documentation and clear communication channels help bridge geographical and cultural gaps, fostering trust and smooth operations.

Conclusion

For international B2B buyers sourcing applique dresses, a deep understanding of manufacturing processes and quality assurance protocols is essential to secure reliable partnerships and deliver superior products to their markets. By focusing on meticulous material preparation, skilled applique application, precise assembly, and stringent QC aligned with international standards, buyers can confidently navigate complex supply chains. Leveraging supplier audits, third-party inspections, and comprehensive quality documentation will further empower buyers across Africa, South America, the Middle East, and Europe to achieve consistent excellence in applique dress sourcing.

Related Video: Amazing Garment Manufacturing Process from Fabric to Finished Product Inside the Factory

Comprehensive Cost and Pricing Analysis for applique dress Sourcing

Breakdown of Cost Components in Applique Dress Sourcing

When sourcing applique dresses for international B2B purposes, understanding the underlying cost structure is essential to negotiate effectively and optimize your purchase. The total cost typically comprises several key components:

-

Materials: This includes the base fabric (commonly cotton, viscose, or blends), applique materials (such as lace, embroidery threads, beads), and any specialty trims or sustainable fabrics. Material quality and certifications (e.g., GOTS organic cotton) significantly affect costs.

-

Labor: Skilled labor is crucial for applique detailing, which is often hand-stitched or requires intricate machine work. Labor costs vary widely by manufacturing country, with India or Bangladesh offering competitive rates compared to Europe or the Middle East.

-

Manufacturing Overhead: Factory operational costs including utilities, machinery depreciation, and administrative expenses. Efficient factories with modern equipment can reduce overhead per unit.

-

Tooling and Setup: Initial costs for pattern making, sample development, and applique templates. These are usually one-time or amortized over large orders.

-

Quality Control (QC): Includes in-line and final inspections to ensure applique precision, fabric integrity, and overall garment quality. Higher QC standards may increase costs but reduce returns and enhance brand reputation.

-

Logistics: Freight, customs duties, insurance, and warehousing costs. Shipping terms (Incoterms) affect who bears these expenses, influencing total landed cost.

-

Margins: Both manufacturer and supplier margins are built into the price. Margins vary based on brand positioning, order volume, and exclusivity.

Key Price Influencers for Applique Dresses

Several factors can shift pricing significantly:

-

Order Volume and Minimum Order Quantities (MOQs): Larger volumes typically yield lower unit costs due to economies of scale. However, some suppliers impose MOQs that may be challenging for smaller buyers.

-

Design Complexity and Customization: More intricate applique patterns, color variations, or bespoke designs increase labor and tooling costs.

-

Material Choices and Certifications: Organic or sustainably sourced fabrics and certified applique materials command price premiums but appeal to eco-conscious markets.

-

Quality Standards: Buyers demanding premium quality or compliance with international standards (e.g., OEKO-TEX) should anticipate higher costs.

-

Supplier Reputation and Location: Established suppliers with reliable delivery and ethical practices may price higher but reduce risk. Sourcing from emerging markets offers cost advantages but requires due diligence.

-

Incoterms and Payment Terms: Terms like FOB, CIF, or DDP determine when and where risk and cost transfer, affecting pricing and cash flow.

Strategic Tips for International B2B Buyers

For buyers in Africa, South America, the Middle East, and Europe aiming to source applique dresses competitively:

-

Negotiate Beyond Price: Discuss payment terms, lead times, quality guarantees, and after-sales support. Flexible terms can add value beyond mere unit cost.

-

Calculate Total Cost of Ownership (TCO): Consider all costs from production to delivery, including customs, tariffs, and potential rework. TCO provides a more accurate financial picture than unit price alone.

-

Leverage Volume Consolidation: Partner with other buyers or place larger, less frequent orders to reduce per-unit costs and access better supplier terms.

-

Prioritize Supplier Transparency: Verify supplier certifications, factory audits, and compliance with labor laws to mitigate reputational and operational risks.

-

Understand Pricing Nuances by Region: For example, buyers in Europe (e.g., Spain) may face higher import duties and stricter quality regulations, while South American buyers should factor in longer shipping times and variable tariffs.

-

Use Incoterms Wisely: Choose terms that align with your logistical capabilities and risk appetite. DDP (Delivered Duty Paid) can simplify import processes but usually carries a higher price.

Disclaimer on Pricing

Due to the dynamic nature of raw material markets, labor rates, and global logistics, prices for applique dresses can fluctuate significantly. The figures discussed here are indicative and should be validated through direct supplier quotations tailored to your specific order requirements and sourcing locations.

By dissecting the cost components and influencing factors, international B2B buyers can approach applique dress sourcing with greater confidence and strategic insight, ultimately securing better deals and fostering sustainable supplier partnerships.

Spotlight on Potential applique dress Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘applique dress’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for applique dress

Critical Technical Properties of Applique Dresses

When sourcing applique dresses, understanding key technical specifications ensures quality, consistency, and alignment with your market needs. Here are the essential properties to evaluate:

-

Fabric Quality and Composition

Applique dresses often use base fabrics like cotton, chiffon, or polyester blends. The fabric’s thread count, weight (gsm), and fiber content affect drape, comfort, and durability. For B2B buyers, specifying the exact fabric composition and quality grade prevents discrepancies and ensures the garment meets end-customer expectations. -

Applique Material and Attachment Method

The applique itself may be crafted from lace, embroidered patches, sequins, or cut fabric pieces. The attachment technique—whether hand-sewn, machine-stitched, or heat-pressed—affects the dress’s aesthetic and longevity. Buyers should confirm these details to balance visual appeal with wear resistance. -

Color Fastness and Dye Quality

Since applique dresses combine multiple fabrics and embellishments, consistent color fastness is critical to avoid fading or bleeding during washing. Ask suppliers for dye type (reactive, vat, or pigment) and colorfastness test results to ensure product reliability across regions with varied washing habits. -

Dimensional Tolerance and Size Accuracy

Precision in garment measurements and applique placement is vital for maintaining design integrity, especially in bulk orders. Typical tolerances range from ±0.5 cm to ±1 cm depending on dress complexity. Clear tolerance standards minimize returns and customer dissatisfaction. -

Seam Strength and Stitch Density

Seams supporting applique areas require higher stitch density and strength to prevent detachment. Verify the stitch count per inch (SPI) and seam type (e.g., flatlock, overlock) to ensure durability, particularly for markets with active wear or special occasion use. -

Care Labeling and Compliance

Proper labeling with washing instructions, fiber content, and country of origin is often mandatory. Compliance with international standards (such as OEKO-TEX or REACH) can be a decisive factor for buyers targeting eco-conscious markets in Europe or the Middle East.

Common Trade Terminology for Applique Dress Procurement

Familiarity with industry jargon streamlines communication and negotiation with suppliers. Here are key terms every B2B buyer should know:

-

OEM (Original Equipment Manufacturer)

This refers to manufacturers producing garments based on your brand’s designs and specifications. OEM partnerships allow customization while leveraging supplier expertise, ideal for buyers seeking private-label applique dresses. -

MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier agrees to produce in a single order. Understanding MOQs helps buyers plan inventory, control costs, and negotiate better pricing, especially critical for emerging markets with budget constraints. -

RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers requesting detailed pricing and terms for specific products. A well-prepared RFQ with clear technical specs accelerates supplier responses and facilitates accurate cost comparisons. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers regarding shipping, insurance, and customs clearance. Common terms include FOB (Free On Board) and CIF (Cost, Insurance, Freight). Clarifying Incoterms upfront prevents costly misunderstandings in international trade. -

Lead Time

This indicates the total time from order confirmation to product delivery. For applique dresses, lead times vary based on complexity and production method. Buyers should confirm lead times aligned with seasonal demands to avoid stockouts. -

Sampling

Sampling is the process of producing a prototype garment before mass production. It allows buyers to verify design, fit, and quality. Insisting on samples reduces risks and ensures alignment with your brand standards.

By mastering these technical properties and trade terms, international B2B buyers can confidently source high-quality applique dresses that meet market demands and optimize supply chain efficiency. This knowledge is particularly valuable when navigating diverse regulatory environments and consumer preferences across Africa, South America, the Middle East, and Europe.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the applique dress Sector

Market Overview & Key Trends

The applique dress sector operates within a vibrant global fashion ecosystem, driven by increasing consumer demand for unique, artisanal aesthetics combined with modern wearability. For international B2B buyers, particularly those sourcing from or selling in Africa, South America, the Middle East, and Europe (including markets like Spain and Brazil), understanding regional market dynamics is crucial to capitalizing on growth opportunities.

Globally, the applique dress market is influenced by several key drivers:

-

Rising Consumer Preference for Craftsmanship: Applique dresses, characterized by decorative fabric patches sewn onto garments, appeal to consumers valuing hand-crafted details and cultural artistry. This trend is especially strong in African and South American markets where traditional textile crafts are integral to fashion identity.

-

Digital Transformation in Sourcing: B2B buyers are increasingly leveraging digital platforms for streamlined sourcing and supplier vetting. Virtual sampling, 3D garment visualization, and AI-enabled trend forecasting tools enable faster decision-making and reduce time-to-market for applique dress collections.

-

Demand for Customization and Limited Editions: Retailers in Europe and the Middle East are focusing on limited runs and bespoke applique designs to differentiate their offerings in saturated markets. This fuels demand for flexible manufacturing partners capable of small-batch production with quality control.

-

Emergence of Regional Production Hubs: Countries like India and Turkey continue to be pivotal in applique dress manufacturing due to their skilled labor force and competitive pricing. Meanwhile, localized sourcing within Africa and South America is gaining traction, driven by initiatives to reduce lead times and support local economies.

-

Sourcing Challenges and Logistics: Buyers must navigate complexities such as fluctuating raw material costs, customs regulations, and shipping timelines. For example, South American importers face longer transit times from Asian suppliers, prompting interest in regional suppliers or nearshoring strategies.

By aligning sourcing strategies with these trends, B2B buyers can optimize cost, quality, and responsiveness in the applique dress sector, ensuring competitive advantage across diverse international markets.

Sustainability & Ethical Sourcing in B2B

Sustainability has become a non-negotiable factor in the fashion supply chain, and the applique dress segment is no exception. The environmental footprint of applique dresses is influenced by fabric choices, embellishment techniques, and manufacturing processes. For B2B buyers committed to responsible sourcing, integrating sustainable practices is both a market differentiator and a compliance necessity.

Illustrative Image (Source: Google Search)

Key sustainability considerations include:

-

Eco-Friendly Fabrics: Organic cotton, linen blends, hemp, and recycled yarns are increasingly preferred substrates for applique dresses. These materials reduce water consumption, chemical usage, and carbon emissions compared to conventional fabrics.

-

Low-Impact Dyes and Treatments: The applique process often involves additional dyeing and finishing stages. Choosing suppliers who utilize low-impact, non-toxic dyes and water-saving technologies helps minimize pollution.

-

Ethical Labor Practices: Ensuring fair wages, safe working conditions, and adherence to labor rights is critical, especially when sourcing from emerging markets in Africa and South America. Certifications like Fair Trade and SA8000 provide assurance of ethical supply chains.

-

Certifications and Standards: Buyers should seek suppliers with recognized certifications such as GOTS (Global Organic Textile Standard) for organic fibers, OEKO-TEX for chemical safety, and Bluesign for environmental management. These certifications validate sustainability claims and facilitate transparent sourcing.

-

Waste Reduction and Circularity: Innovative applique techniques that minimize fabric scraps and support garment repair or upcycling contribute to circular fashion models. B2B buyers can encourage suppliers to adopt zero-waste pattern making and modular applique designs.

By prioritizing sustainability and ethical sourcing, B2B buyers not only meet growing regulatory and consumer expectations but also foster long-term supplier partnerships and brand loyalty in global markets.

Brief Evolution and Historical Context

Applique as a decorative technique dates back centuries and spans multiple cultures, making it a rich source of inspiration for contemporary applique dresses. Traditionally, applique involved sewing ornamental patches onto textiles for both functional reinforcement and artistic expression. In regions like Africa, intricate applique patterns are deeply woven into cultural identity, while in Europe, it has historical ties to haute couture embellishments.

The modern applique dress sector has evolved from these artisanal roots into a dynamic fusion of tradition and innovation. Advances in textile technology and manufacturing now allow for more complex, durable, and scalable applique designs. This evolution has opened new avenues for B2B buyers seeking to blend heritage craftsmanship with modern fashion demands, especially in markets where cultural storytelling through apparel adds significant value.

Understanding this lineage helps buyers appreciate the intrinsic value of applique dresses, guiding sourcing decisions that respect craftsmanship while leveraging contemporary production efficiencies.

Related Video: International Trade Explained

Frequently Asked Questions (FAQs) for B2B Buyers of applique dress

-

How can I effectively vet applique dress suppliers from different regions such as India, China, or Turkey?

Start by verifying the supplier’s business licenses, certifications (like ISO or OEKO-TEX), and factory audits to ensure compliance with international standards. Request detailed product samples and assess their quality, craftsmanship, and material authenticity. Check references or client testimonials, especially from buyers in Africa, South America, the Middle East, and Europe. Utilize platforms that offer verified supplier profiles and consider arranging virtual or on-site factory visits. Clear communication about your design and quality expectations from the outset will help identify reliable partners. -

What customization options are typically available for applique dresses when ordering in bulk?

Most manufacturers offer customization including fabric choice, applique design patterns, color variations, embroidery styles, sizing adjustments, and packaging. Digital prototyping tools and sample approvals allow you to refine designs before mass production. For international buyers, it’s critical to confirm the supplier’s ability to replicate your specific applique details consistently. Custom labels, hangtags, and sustainable packaging can also be requested to align with your brand identity and regional market preferences. -

What are the common minimum order quantities (MOQs) and lead times for applique dress production?

MOQs vary widely depending on supplier capabilities and complexity of applique work, typically ranging from 100 to 500 pieces per style. Smaller MOQs may be available but often at higher per-unit costs. Lead times usually span 45 to 90 days, factoring in design finalization, material sourcing, production, and quality checks. Plan orders well in advance, especially if sourcing for peak seasons or festivals in your target markets. Negotiate flexible MOQs and expedited production for initial test orders when possible. -

What payment terms are standard for international B2B transactions involving applique dresses?

Common terms include a 30% deposit upfront with the balance paid before shipment or upon receiving shipping documents. Letters of credit (LC) offer added security for larger orders but may incur additional banking fees. Some suppliers accept PayPal or escrow services for initial orders. Always clarify currency, payment deadlines, and penalties for late payments. Use contracts to define these terms explicitly and protect your interests, especially when dealing with new or overseas partners. -

How can I ensure consistent quality control for applique dresses when working with overseas manufacturers?

Implement a multi-stage quality control process including pre-production sample approval, inline inspections during manufacturing, and final quality audits before shipment. Engage third-party inspection agencies familiar with textile and applique standards to conduct factory visits and random checks. Specify clear quality benchmarks such as stitch density, applique adhesion, colorfastness, and fabric integrity. Digital reporting with photos and videos can supplement onsite inspections, providing transparency and reducing the risk of defective shipments. -

Are there specific certifications or standards I should look for when sourcing applique dresses internationally?

Yes, prioritize suppliers with certifications such as GOTS (Global Organic Textile Standard) for organic materials, OEKO-TEX Standard 100 for harmful substance testing, and SA8000 for social accountability. Compliance with REACH regulations is critical for European buyers to ensure chemical safety. Certifications demonstrate commitment to sustainability, ethical labor, and product safety, which are increasingly demanded by global consumers. Request documentation upfront and verify authenticity through official certification bodies. -

What logistics considerations should I be aware of when importing applique dresses from Asia or other manufacturing hubs?

Understand import duties, taxes, and customs regulations specific to your country, as these affect landed costs. Choose freight methods balancing cost and speed—sea freight is economical for large orders but slower, while air freight suits urgent shipments at a premium. Coordinate with freight forwarders experienced in textile shipments to manage packaging, labeling, and documentation efficiently. Consider the impact of seasonal weather on transit times and potential delays due to customs inspections or geopolitical events. -

How should I handle disputes or quality issues if the applique dresses do not meet agreed specifications upon delivery?

First, maintain clear and documented communication throughout the order lifecycle, including specifications, approvals, and inspection reports. If issues arise, notify the supplier immediately with evidence such as photos and detailed descriptions. Negotiate remedies like rework, partial refunds, or replacement shipments. Leverage contract clauses related to quality guarantees and dispute resolution mechanisms such as arbitration or mediation. Building strong relationships with suppliers who prioritize customer satisfaction helps mitigate conflicts effectively.

Strategic Sourcing Conclusion and Outlook for applique dress

The strategic sourcing of applique dresses is a critical factor in achieving competitive advantage and sustainable growth in the global fashion marketplace. For international B2B buyers from Africa, South America, the Middle East, and Europe, success hinges on selecting manufacturing partners who combine technical expertise, ethical sourcing, and flexible production capabilities. Prioritizing suppliers that offer quality materials—such as organic fabrics and eco-friendly embellishments—while maintaining efficient lead times and scalable minimum order quantities will help meet evolving consumer demands and regulatory standards.

Illustrative Image (Source: Google Search)

Key takeaways for buyers include:

- Align sourcing strategies with brand values and sustainability goals to enhance market appeal and compliance.

- Leverage digital design and prototyping tools to reduce time-to-market and minimize costly revisions.

- Evaluate supplier reliability and quality control rigor to ensure consistent product excellence.

- Optimize logistics and customs planning to avoid delays and unexpected costs in cross-border trade.

Looking ahead, the applique dress segment is poised for innovation through sustainable materials and advanced manufacturing techniques such as digital embroidery and 3D embellishments. Buyers who embrace a proactive, data-driven sourcing approach will not only secure high-quality products but also build resilient supply chains adaptable to shifting global trends.

For B2B buyers seeking to capitalize on this dynamic market, now is the time to forge strategic partnerships with forward-thinking manufacturers that can deliver creativity, quality, and sustainability at scale. This will unlock new growth opportunities across diverse international markets.