Your Ultimate Guide to Sourcing Empire Waist Wedding Dress

Guide to Empire Waist Wedding Dress

- Introduction: Navigating the Global Market for empire waist wedding dress

- Understanding empire waist wedding dress Types and Variations

- Key Industrial Applications of empire waist wedding dress

- Strategic Material Selection Guide for empire waist wedding dress

- In-depth Look: Manufacturing Processes and Quality Assurance for empire waist wedding dress

- Manufacturing Process of Empire Waist Wedding Dresses

- Quality Assurance and Control Framework

- Verifying Supplier QC: Practical Strategies for B2B Buyers

- Nuances for International B2B Buyers

- Conclusion

- Comprehensive Cost and Pricing Analysis for empire waist wedding dress Sourcing

- Spotlight on Potential empire waist wedding dress Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for empire waist wedding dress

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the empire waist wedding dress Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of empire waist wedding dress

- Strategic Sourcing Conclusion and Outlook for empire waist wedding dress

Introduction: Navigating the Global Market for empire waist wedding dress

The empire waist wedding dress stands as a timeless symbol of elegance and versatility in the bridal apparel market. Its distinctive silhouette—characterized by a fitted bodice just below the bust and a flowing skirt—offers a flattering and universally appealing style that caters to diverse body types and cultural preferences. For international B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, understanding the nuances of this dress style is essential to capitalize on growing bridal fashion trends and meet evolving consumer demands.

This guide provides a comprehensive roadmap for sourcing empire waist wedding dresses with confidence and strategic insight. It covers a broad spectrum of critical factors including the various types of empire waist designs, choice of fabrics and embellishments, manufacturing best practices, and quality control standards that ensure product excellence. Additionally, it offers an in-depth look at supplier selection criteria, cost considerations, and market dynamics specific to key global regions such as Egypt and Spain.

By delving into these aspects, buyers will gain actionable knowledge to streamline procurement processes, reduce risk, and negotiate favorable terms with manufacturers and wholesalers. The guide also addresses frequently asked questions to clarify common sourcing challenges, empowering buyers to make informed decisions that align with their business objectives and customer expectations. Ultimately, this resource is designed to elevate the buying experience and enhance competitive advantage in the vibrant global market for empire waist wedding dresses.

Understanding empire waist wedding dress Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Classic Empire Waist | Fitted bodice ending just below bust, flowing skirt | Bridal boutiques, luxury wedding dress retailers | Elegant and timeless; broad appeal but may require diverse sizing |

| Bohemian Empire Waist | Lightweight fabrics, lace overlays, often off-shoulder | Specialty bridal stores, boho-chic wedding vendors | Trendy and versatile; niche market with seasonality considerations |

| Modern Minimalist | Clean lines, minimal embellishments, often strapless | Contemporary bridal brands, urban wedding markets | Appeals to modern brides; limited decorative options may deter some |

| Plus-Size Empire Waist | Enhanced support, wider straps, tailored fit for curves | Inclusive bridal shops, plus-size fashion suppliers | Comfort and flattering fit; requires specialized sizing inventory |

| Embellished Empire Waist | Decorative elements like beading, embroidery, or appliqué | High-end boutiques, custom dressmakers | High perceived value; higher production cost and longer lead times |

Classic Empire Waist

This traditional style features a fitted bodice just below the bust with a flowing skirt, creating an elegant and flattering silhouette that elongates the torso. Ideal for bridal boutiques targeting a wide demographic, it suits formal and semi-formal weddings across diverse cultural markets such as Europe and the Middle East. B2B buyers should focus on offering a broad range of sizes and fabrics to accommodate different climates and preferences. Its timeless appeal ensures consistent demand but requires inventory flexibility to match regional sizing standards.

Bohemian Empire Waist

Characterized by lightweight materials like chiffon or lace and often incorporating off-shoulder or flutter sleeves, this variation appeals to the boho-chic wedding segment popular in South America and parts of Africa. Suppliers targeting niche bridal stores should consider seasonality and fabric sourcing for warm climates. The bohemian style’s relaxed yet romantic look resonates with younger brides seeking non-traditional gowns. Buyers should prioritize partnerships with designers skilled in delicate fabric handling and trend-responsive collections.

Modern Minimalist

Defined by sleek silhouettes with minimal adornment, often strapless or with thin straps, this style targets contemporary urban markets, including cosmopolitan areas in Europe and the Middle East. It suits buyers aiming to attract brides who prefer understated elegance and modern aesthetics. This variation demands high-quality fabric and precise tailoring to maintain structure without embellishments. B2B purchasers should emphasize quality control and offer customization options to meet client expectations for simplicity paired with sophistication.

Plus-Size Empire Waist

Designed with enhanced support features such as wider straps and reinforced bodices, this variation caters to the plus-size bridal market, which is growing globally. Retailers and manufacturers serving inclusive bridal shops in Africa, Europe, and South America benefit from investing in this category. Buyers must ensure access to specialized sizing and tailoring expertise to provide comfortable, flattering fits. Offering plus-size empire waist dresses expands market reach and addresses increasing demand for diversity and body positivity.

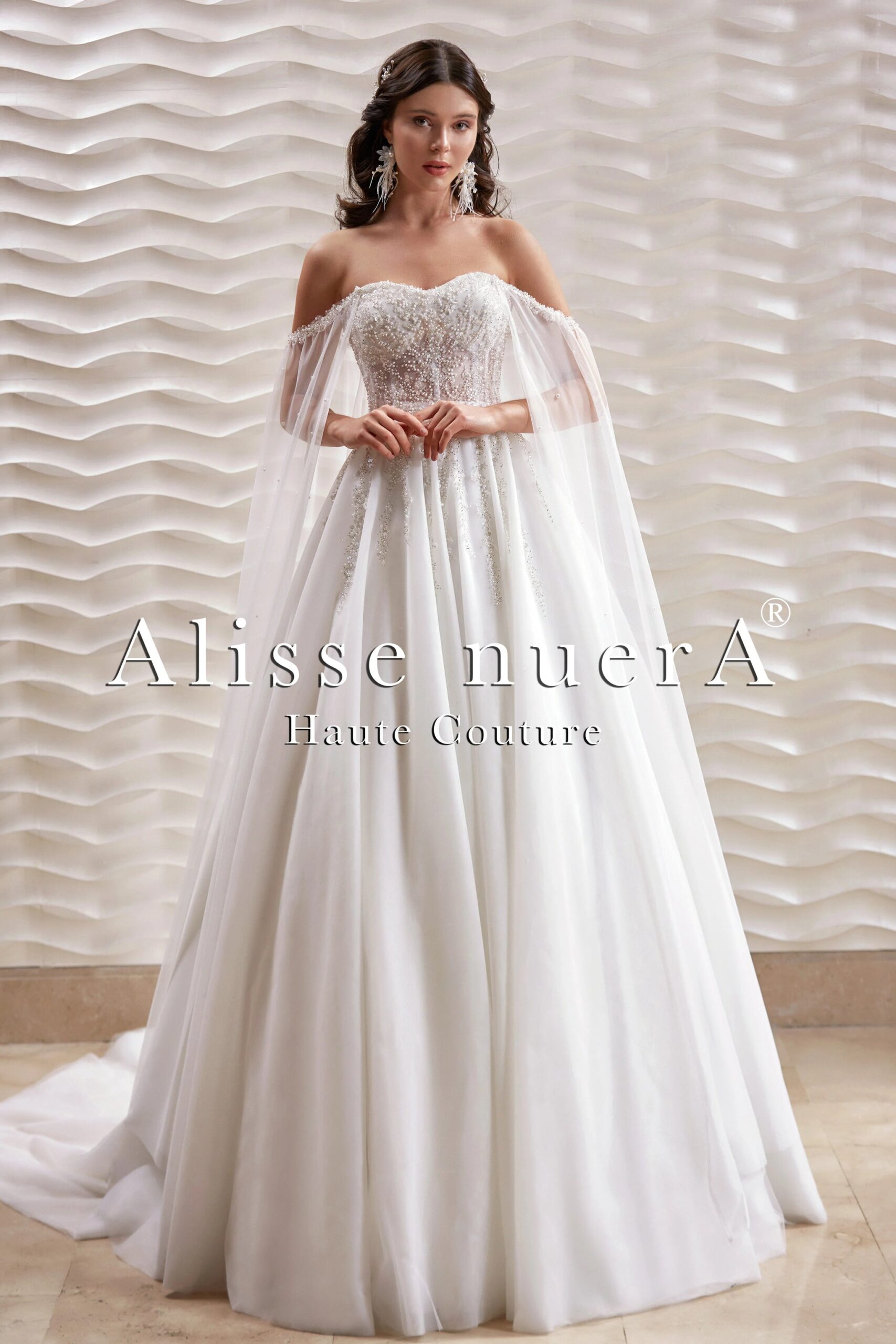

Embellished Empire Waist

Featuring intricate beading, embroidery, or appliqué, this variation appeals to the luxury segment and clients seeking standout gowns for formal weddings. High-end boutiques and custom dressmakers in regions with affluent clientele, such as the Middle East and parts of Europe, find this style profitable. B2B buyers should be prepared for longer production lead times and higher costs due to detailed craftsmanship. Investing in skilled artisans and premium materials is critical to maintaining quality and exclusivity.

Related Video: DIY Beginner Friendly Dress Tutorial | Simple Empire Waist Sundress

Key Industrial Applications of empire waist wedding dress

| Industry/Sector | Specific Application of Empire Waist Wedding Dress | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Bridal Retail & Boutiques | Stocking versatile bridal gowns for diverse customer bases | Broad appeal due to flattering silhouette, increasing sales opportunities | Variety in fabrics, sizes, and customization options; cultural preferences |

| Wedding Event Planning | Providing rental or styling services for weddings | Enhances client satisfaction with classic, elegant dress options | Durability for multiple wears, ease of cleaning, and maintenance |

| Fashion Manufacturing | Designing seasonal collections emphasizing romantic styles | Meets demand for timeless, flattering wedding dress silhouettes | Quality of materials, skilled craftsmanship, and cost efficiency |

| Export & Wholesale | Supplying empire waist dresses to international markets | Access to growing wedding markets in Africa, South America, Middle East, Europe | Compliance with international trade standards, packaging, and shipping logistics |

| Online Bridal Marketplaces | Offering curated selections for global customers | Increased reach and convenience for buyers worldwide | Accurate sizing guides, detailed product descriptions, and return policies |

The Bridal Retail & Boutiques sector benefits significantly from incorporating empire waist wedding dresses into their inventory. This silhouette appeals to a broad range of brides due to its flattering design that elongates the torso and provides comfort by not clinging to the midsection. For B2B buyers in regions like Egypt or Spain, sourcing a variety of fabrics and styles that reflect local tastes and climate conditions is essential. Offering customization options can further enhance market competitiveness.

In Wedding Event Planning, empire waist dresses are ideal for rental services or styling packages. Their timeless and romantic appeal suits many wedding themes, which helps planners meet diverse client expectations. For event planners operating across continents, such as in South America or the Middle East, selecting dresses that are durable and easy to maintain after multiple rentals is crucial to maximize return on investment and client satisfaction.

Fashion Manufacturing companies focusing on bridal collections find empire waist dresses to be a staple due to their enduring popularity. This style aligns well with seasonal trends emphasizing romantic and ethereal looks. Buyers in Europe and Africa should prioritize high-quality materials and skilled tailoring to produce dresses that meet the expectations of discerning international markets while keeping production costs manageable to maintain profitability.

For Export & Wholesale businesses, empire waist wedding dresses represent an opportunity to tap into expanding wedding markets globally. Countries in Africa and the Middle East, for example, are witnessing increased demand for elegant bridal wear that balances tradition and modernity. B2B buyers must ensure compliance with international trade regulations, optimize packaging for long-distance shipping, and coordinate logistics to maintain product integrity during transport.

Finally, Online Bridal Marketplaces leverage the empire waist dress’s popularity by offering curated selections accessible to global customers. This channel allows buyers from remote or underserved regions to access a wide variety of styles conveniently. Critical considerations include providing accurate sizing charts, comprehensive product information, and flexible return policies to build trust and reduce purchase hesitation among international buyers, especially in diverse markets like South America and Europe.

Related Video: make the perfect dress in 3 hours [SEWING TUTORIAL]

Strategic Material Selection Guide for empire waist wedding dress

When selecting materials for empire waist wedding dresses, B2B buyers must consider fabric properties that influence comfort, drape, durability, and cultural preferences across diverse international markets such as Africa, South America, the Middle East, and Europe. The right material not only defines the aesthetic appeal but also affects manufacturing complexity, cost, and end-user satisfaction. Below is an analysis of four common materials used in empire waist wedding dresses, with actionable insights for international buyers.

Silk

Key Properties:

Silk is a natural protein fiber known for its luxurious sheen, excellent drape, and breathability. It offers moderate tensile strength but is sensitive to moisture and sunlight, which can degrade fibers over time.

Pros & Cons:

Silk provides an elegant, flowing silhouette ideal for the billowy skirts of empire waist dresses. It is lightweight and comfortable in warm climates, making it suitable for regions like Egypt and parts of South America. However, silk is costly and requires delicate handling during manufacturing, including specialized sewing techniques and finishing processes. Its susceptibility to staining and water damage can increase aftercare costs.

Impact on Application:

Silk’s natural breathability and softness make it perfect for high-end bridal wear where comfort and luxury are paramount. However, its delicate nature means it may not be ideal for heavy embellishments or structured designs without reinforcement.

Considerations for International Buyers:

Buyers in Africa and the Middle East should ensure silk complies with international textile standards such as OEKO-TEX for chemical safety. European buyers often demand certifications related to sustainability and ethical sourcing. Silk imports may attract tariffs or require compliance with specific customs regulations, especially in South America. Partnerships with certified silk suppliers can mitigate risks related to quality and supply chain transparency.

Chiffon

Key Properties:

Chiffon is a lightweight, sheer fabric traditionally made from silk but now often from polyester or nylon blends. It has a slightly rough texture and excellent drape, with moderate tear resistance.

Pros & Cons:

Chiffon’s airy, floaty quality complements the empire waist’s romantic silhouette, making it popular for overlays and skirts. It is more affordable than pure silk and easier to care for, especially synthetic variants. However, chiffon can be prone to snagging and requires skilled handling during cutting and sewing to avoid distortion.

Impact on Application:

Chiffon is versatile for both casual and formal wedding dresses, suitable for warm climates due to its breathability. Its translucency allows layering, which can add depth to the dress design without bulk.

Considerations for International Buyers:

Synthetic chiffon is often preferred in markets like the Middle East and Africa due to its durability and lower cost. Buyers should verify compliance with ASTM or ISO standards for synthetic textiles to ensure fabric strength and colorfastness. In Europe, eco-conscious buyers may seek chiffon made from recycled fibers or biodegradable synthetics.

Satin

Key Properties:

Satin is defined by its weave rather than fiber content, typically made from silk, polyester, or acetate. It has a glossy surface and a dull back, with a smooth, heavy drape and moderate wrinkle resistance.

Pros & Cons:

Satin’s lustrous finish enhances the formal appeal of empire waist gowns, especially for evening or winter weddings. It is relatively durable and holds shape well, supporting structured bodices. However, satin can be heavy and less breathable, potentially uncomfortable in hot climates. It also tends to show imperfections like puckering or pulls easily.

Impact on Application:

Satin is ideal for buyers targeting markets with cooler climates such as parts of Europe (e.g., Spain) or for evening wedding collections. Its weight supports intricate embroidery and beadwork, often favored in Middle Eastern bridal fashion.

Considerations for International Buyers:

Buyers should assess the fiber content to balance cost and quality; polyester satin is more affordable but less luxurious than silk satin. Compliance with DIN or JIS textile standards may be required in European or Asian markets. Satin’s heavier weight can increase shipping costs, an important factor for buyers in Africa and South America.

Organza

Key Properties:

Organza is a thin, plain weave fabric traditionally made from silk but now also from synthetic fibers like polyester. It is crisp, sheer, and holds shape well, with moderate tensile strength and low elasticity.

Pros & Cons:

Organza adds volume and structure without weight, perfect for creating the billowy skirts characteristic of empire waist dresses. It is more affordable and easier to maintain than silk but can be stiff and less comfortable directly against the skin.

Impact on Application:

Organza is widely used in layered designs and overlays to achieve a dramatic, ethereal effect. Its stiffness supports architectural silhouettes and is favored in formal bridal collections.

Considerations for International Buyers:

Synthetic organza is preferred in markets where cost and durability are priorities, such as South America and parts of Africa. Buyers should verify compliance with ASTM or ISO standards for synthetic fabrics. In Europe, there is growing demand for organza made from sustainable sources or recycled materials. Shipping considerations include careful packaging to prevent creasing.

| Material | Typical Use Case for empire waist wedding dress | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Silk | Luxury, high-end empire waist gowns with flowing skirts and delicate overlays | Luxurious sheen and excellent drape, breathable and comfortable in warm climates | High cost, delicate handling required, susceptible to staining and moisture damage | High |

| Chiffon | Lightweight, sheer overlays and skirts for airy, romantic looks | Affordable, breathable, versatile for layering | Prone to snagging, requires skilled sewing to avoid distortion | Medium |

| Satin | Structured bodices and formal evening empire waist gowns | Lustrous finish, supports embellishments, wrinkle-resistant | Heavy, less breathable, shows imperfections easily | Medium to High (depends on fiber) |

| Organza | Voluminous skirts and layered designs needing structure without weight | Crisp, sheer, holds shape well | Stiff texture, less comfortable against skin | Medium |

This detailed material selection guide equips international B2B buyers with insights to choose fabrics that align with their target markets’ climatic conditions, cultural preferences, and quality expectations, ensuring competitive and appealing empire waist wedding dress offerings.

In-depth Look: Manufacturing Processes and Quality Assurance for empire waist wedding dress

Manufacturing Process of Empire Waist Wedding Dresses

The production of empire waist wedding dresses involves a sequence of carefully coordinated stages to ensure quality, comfort, and aesthetic appeal. Understanding these stages helps B2B buyers evaluate supplier capabilities and product consistency.

1. Material Preparation

- Fabric Selection: High-quality fabrics such as silk chiffon, satin, tulle, and lace are sourced based on the design requirements. For empire waist gowns, lightweight, flowing fabrics that enhance the dress’s ethereal silhouette are preferred.

- Inspection: Incoming fabrics undergo initial quality checks for color consistency, texture, tensile strength, and absence of defects like holes or stains.

- Cutting: Using precision cutting tools or automated cutting machines, fabric panels are cut according to detailed patterns that reflect the empire waist silhouette—emphasizing the high bust seam and the flowing skirt.

2. Forming the Dress Components

- Bodice Construction: The bodice is crafted to fit snugly just below the bust. Techniques such as boning insertion, darting, and lining are employed to provide structure and comfort.

- Skirt Formation: The skirt panels are shaped to flow freely from the empire seam, often cut in layers or panels to create billowy movement without excessive volume.

- Neckline and Sleeve Detailing: Depending on the design—sweetheart neckline, straps, sleeves—additional fabric shaping or lace overlay application is done at this stage.

3. Assembly

- Sewing: Skilled seamstresses assemble the bodice and skirt, carefully aligning seams to maintain the high waistline’s clean finish.

- Embellishment: Embroidery, beadwork, appliqué, or lace overlays are applied by hand or machine, adhering to design specifications.

- Fittings and Adjustments: Prototypes or initial samples undergo fitting sessions to ensure the empire waistline flatters a variety of body types, a critical factor for international buyers targeting diverse markets.

4. Finishing

- Hemming and Edge Finishing: Skirts are hemmed with precision to prevent fraying while maintaining flow.

- Ironing and Pressing: Final pressing ensures the dress holds its shape and presents a polished appearance.

- Packaging: Dresses are carefully folded or hung in protective covers to prevent damage during shipping.

Quality Assurance and Control Framework

For B2B buyers, especially those operating in Africa, South America, the Middle East, and Europe, understanding and verifying quality assurance (QA) and quality control (QC) processes is crucial to mitigate risks and ensure compliance with international standards.

International and Industry Standards

- ISO 9001: The most relevant global standard for quality management systems, ISO 9001 certification indicates that a manufacturer consistently meets customer and regulatory requirements through effective process control.

- OEKO-TEX Standard 100: Important for fabric safety, this certification ensures textiles are free from harmful substances, which is critical for wedding dresses worn close to skin.

- REACH Compliance (Europe): For European buyers, ensuring suppliers comply with REACH regulations on chemical use in textiles is essential.

- Other Standards: While CE marking is generally not applicable to wedding dresses, compliance with local import regulations and customs documentation is necessary.

QC Checkpoints in Manufacturing

- Incoming Quality Control (IQC): Initial inspection of raw materials (fabric, embellishments) for defects, color fastness, and compliance with technical specifications.

- In-Process Quality Control (IPQC): Continuous monitoring during sewing, assembly, and embellishment stages to catch defects early—such as seam integrity, stitch density, and accurate placement of design elements.

- Final Quality Control (FQC): Comprehensive inspection of finished dresses for fit, workmanship, fabric quality, and packaging integrity before shipment.

Common Testing Methods

- Fabric Testing: Includes tensile strength, colorfastness to washing and light, shrinkage, and pilling resistance.

- Fit and Measurement Verification: Comparing garment dimensions against approved samples and tech packs.

- Visual Inspection: Checking for defects such as loose threads, uneven hems, or stains.

- Functional Tests: For components like zippers and buttons to ensure durability.

Verifying Supplier QC: Practical Strategies for B2B Buyers

For buyers from regions like Egypt, Spain, Brazil, Nigeria, or Saudi Arabia, ensuring the reliability of a supplier’s QC system requires proactive engagement and verification:

- Factory Audits: Conduct or commission on-site audits to evaluate the production environment, worker skill levels, and adherence to documented quality processes. Use internationally recognized audit frameworks such as BSCI or Sedex for ethical and quality compliance.

- Reviewing QC Reports: Request detailed IQC, IPQC, and FQC reports with photographic evidence and defect rate statistics. Consistent reporting reflects supplier transparency.

- Third-Party Inspections: Employ independent inspection agencies (e.g., SGS, Intertek) to perform random sampling and quality verification before shipment.

- Sample Approval Processes: Insist on pre-production and pre-shipment samples to verify adherence to design and quality standards.

- Certifications Verification: Confirm validity of ISO 9001 and OEKO-TEX certificates through official registries or certification bodies.

Nuances for International B2B Buyers

- Cultural and Regional Fit Considerations: Buyers should communicate specific fit preferences or regional sizing differences, as empire waist dresses may require adjustments to suit local body shapes and climate preferences.

- Compliance with Import Regulations: For Middle Eastern buyers, materials and embellishments must comply with halal or local customs restrictions. European buyers should verify compliance with EU textile labeling regulations.

- Logistics and Packaging: Proper packaging to withstand long-distance shipping is critical, especially for buyers in Africa and South America where transit conditions can be challenging.

- Language and Communication: Clear, documented communication about quality standards and expectations helps avoid misunderstandings, particularly when working across language barriers.

- Sustainability and Ethical Manufacturing: Increasingly, buyers from Europe and South America prioritize eco-friendly materials and ethical labor practices, which can be a differentiator when selecting suppliers.

Conclusion

For international B2B buyers sourcing empire waist wedding dresses, a deep understanding of manufacturing processes and quality assurance is vital to secure high-quality, consistent products. By focusing on detailed supplier evaluations, adherence to international standards, and rigorous QC checkpoints, buyers can confidently meet their market’s expectations and build lasting supplier partnerships.

Related Video: Amazing Garment Manufacturing Process from Fabric to Finished Product Inside the Factory

Comprehensive Cost and Pricing Analysis for empire waist wedding dress Sourcing

When sourcing empire waist wedding dresses for international B2B markets, understanding the detailed cost structure and pricing dynamics is critical for making informed purchasing decisions. This section breaks down the key cost components, price influencers, and strategic buyer tips to optimize procurement, especially for buyers from Africa, South America, the Middle East, and Europe.

Key Cost Components in Empire Waist Wedding Dress Production

- Materials

The fabric choice significantly impacts costs. Common materials include chiffon, silk, tulle, and lace, with silk and high-quality lace driving prices higher. Embellishments such as beading or embroidery add further cost layers. For empire waist styles, the fabric requirements can be moderate since the skirt flows from below the bust, but premium materials remain a primary cost driver.

Illustrative Image (Source: Google Search)

-

Labor

Skilled labor is essential, especially for intricate details like bodice fitting, lace overlays, and delicate stitching. Labor costs vary widely by country and factory expertise. Countries with established garment manufacturing hubs can offer competitive rates, but buyers should weigh this against quality and delivery reliability. -

Manufacturing Overhead

Overhead includes utilities, factory management, machinery depreciation, and quality control operations. Efficient factories with modern equipment tend to have optimized overhead costs, which can translate into better pricing for buyers. -

Tooling and Development

Initial costs for pattern making, sample development, and prototype adjustments are often amortized over order volumes. Custom designs or modifications to standard empire waist patterns increase tooling costs. -

Quality Control (QC)

QC processes ensure compliance with specifications and standards, especially important for international buyers requiring consistent quality. QC costs cover inspections, testing, and potential reworks. -

Logistics and Shipping

International freight, customs duties, and insurance add to the landed cost. Shipping modes (sea, air) and Incoterms chosen will affect timing and cost. For buyers in regions like Africa or South America, sea freight is common for cost efficiency but requires longer lead times. -

Supplier Margin

Factories and agents include a margin to cover profit and risk. Negotiating this component depends on order volume, relationship maturity, and market competition.

Influential Pricing Factors to Consider

-

Order Volume and Minimum Order Quantity (MOQ)

Larger volumes typically reduce unit costs due to economies of scale. However, some suppliers impose MOQs that may be challenging for smaller importers. Negotiating flexible MOQs or phased order fulfillment can improve cost efficiency. -

Design Specifications and Customization

Custom necklines, sleeve styles, or embellishments increase complexity and price. Standardized designs are more cost-effective. Buyers should balance unique design features against budget constraints. -

Material Quality and Certifications

High-grade fabrics and certifications (e.g., OEKO-TEX, organic) command premium prices but can justify higher retail pricing in discerning markets. Buyers targeting European or Middle Eastern markets may prioritize certified sustainable materials. -

Supplier Reliability and Factory Location

Established suppliers with proven track records may charge a premium but reduce risks of delays or quality issues. Proximity to shipping hubs also affects logistics costs and lead times. -

Incoterms and Payment Terms

Incoterms like FOB, CIF, or DDP determine cost and risk allocation between buyer and seller. For buyers new to international trade, choosing terms that include shipping and customs (e.g., DDP) can simplify procurement but increase upfront costs.

Strategic Buyer Tips for International B2B Procurement

-

Negotiate Beyond Unit Price

Engage suppliers on payment terms, volume discounts, and lead times. Consider total cost of ownership, including logistics, duties, and potential wastage. -

Leverage Local Market Knowledge

Understand regional import regulations, tariffs, and textile standards. For example, buyers in Egypt or Spain should factor in EU textile import rules or regional trade agreements affecting duties. -

Prioritize Sampling and Quality Assurance

Invest in samples to verify fabric, fit, and craftsmanship before bulk orders. Employ third-party inspections to avoid costly post-shipment disputes. -

Assess Total Cost of Ownership (TCO)

Calculate all costs from factory gate to warehouse, including storage, handling, and potential returns. Sometimes a higher unit price with better quality and lower defects reduces overall expenditure. -

Consider Multi-Sourcing

Diversify suppliers to mitigate risks such as supply chain disruptions or quality inconsistencies, especially important given geopolitical uncertainties affecting global logistics. -

Stay Informed on Market Trends

Material costs fluctuate due to global cotton or silk prices, and labor rates evolve with economic conditions. Regular market analysis helps anticipate pricing shifts.

Indicative Pricing Disclaimer

Prices for empire waist wedding dresses vary widely based on design complexity, materials, order volume, and sourcing geography. Indicative unit costs for mid-range quality dresses typically range from $50 to $150 per piece FOB, with premium or heavily customized options exceeding this band. Buyers should engage directly with suppliers for firm quotations tailored to their specifications and volumes.

Illustrative Image (Source: Google Search)

By thoroughly analyzing the cost components and pricing influencers and applying strategic negotiation and procurement practices, international B2B buyers can secure competitively priced, high-quality empire waist wedding dresses that meet their market demands.

Spotlight on Potential empire waist wedding dress Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ’empire waist wedding dress’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for empire waist wedding dress

Critical Technical Properties of Empire Waist Wedding Dresses

-

Fabric Quality and Grade

The choice of fabric significantly influences the dress’s drape, comfort, and longevity. Common fabrics include chiffon, silk, satin, and tulle, each graded by thread count, weave tightness, and finish. Higher-grade materials offer superior softness and durability, essential for markets like Europe and the Middle East where luxury is a priority. For B2B buyers, specifying fabric grade ensures product consistency and meets customer expectations. -

Measurement Tolerance and Fit Precision

Empire waist dresses require precise tailoring, especially around the bodice just below the bust, where the waistline sits. Measurement tolerance typically ranges between ±0.5 to 1 cm for critical dimensions to maintain the flattering silhouette. For international buyers, understanding tolerance helps in quality control and reduces returns due to poor fit.

Illustrative Image (Source: Google Search)

-

Embellishment Detailing Standards

Embellishments such as lace overlays, beadwork, and embroidery must meet strict quality standards in terms of placement accuracy, stitch strength, and material compatibility. These details define the dress’s aesthetic appeal and affect production lead times. Buyers should request samples to verify embellishment quality and consistency. -

Color Fastness and Dye Quality

Colorfastness is crucial, especially for dyed or tinted empire waist dresses. The dye must resist fading under sunlight and washing, maintaining vibrancy for diverse climates, including the intense sun of South America and the humid conditions of parts of Africa. Buyers should confirm compliance with international textile standards like ISO 105 for colorfastness. -

Seam Strength and Construction

The empire waist dress structure depends heavily on strong seams at the bodice and skirt junction. Seam strength tests (e.g., ASTM D1683) ensure durability during wear and transport. For B2B buyers, specifying seam construction techniques (e.g., double-needle stitching) can reduce defects and returns. -

Skirt Volume and Flow Characteristics

The skirt below the empire waist can vary from body-skimming to billowy. Technical properties include fabric weight, layering count, and flexibility to achieve the desired volume without bulk. Understanding these characteristics aids buyers in selecting products that suit their target markets’ style preferences and climate considerations.

Key Industry and Trade Terminology for B2B Buyers

-

OEM (Original Equipment Manufacturer)

Refers to manufacturers producing dresses to a buyer’s exact specifications and branding. OEM partnerships allow buyers to customize designs and control quality, crucial for markets demanding unique styles or private labels. -

MOQ (Minimum Order Quantity)

The smallest quantity a supplier is willing to produce per order. MOQs vary by manufacturer and impact inventory costs and pricing. Buyers from emerging markets like Africa or South America should negotiate MOQs aligned with local demand and storage capacity. -

RFQ (Request for Quotation)

A formal inquiry sent by buyers to suppliers to obtain price, lead time, and terms for specific dress designs or quantities. RFQs are essential for comparing offers and establishing procurement budgets. -

Incoterms (International Commercial Terms)

Standardized trade terms defining responsibilities for shipping, insurance, and customs between buyer and seller. Common terms include FOB (Free On Board) and CIF (Cost, Insurance, Freight). Understanding Incoterms helps buyers from different regions manage logistics and cost allocation effectively. -

Lead Time

The total time from order confirmation to product delivery. Lead times for empire waist wedding dresses depend on complexity, fabric sourcing, and embellishments. Accurate lead time knowledge enables buyers to plan inventory and marketing campaigns accordingly. -

Tech Pack

A detailed document containing all technical specifications, measurements, materials, trims, and construction details required for manufacturing. Providing a comprehensive tech pack minimizes errors and accelerates production, crucial for buyers seeking consistency across multiple shipments.

By mastering these technical properties and trade terms, international B2B buyers—especially from Africa, South America, the Middle East, and Europe—can confidently source high-quality empire waist wedding dresses tailored to their markets’ demands while optimizing procurement efficiency and minimizing risks.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the empire waist wedding dress Sector

Market Overview & Key Trends

The global empire waist wedding dress market is experiencing a resurgence driven by evolving bridal preferences emphasizing romantic, timeless silhouettes that flatter diverse body types. This style’s appeal—characterized by a fitted bodice below the bust and a flowing skirt—resonates strongly with brides seeking comfort combined with elegance, making it a staple across various cultural contexts. For international B2B buyers, especially in emerging and mature markets such as Africa, South America, the Middle East, and Europe, this trend translates into robust demand for versatile designs adaptable to local tastes and climates.

Key market drivers include the growing influence of digital platforms that enable direct engagement between suppliers and boutique retailers, streamlining sourcing processes. Buyers from regions like Egypt and Spain increasingly leverage online wholesale marketplaces and virtual showrooms to access a broader portfolio of manufacturers offering customizable empire waist gowns. Moreover, there is a notable shift towards incorporating regional aesthetics—such as intricate lacework popular in European markets or lightweight, breathable fabrics favored in the Middle East—to better align products with end-customer expectations.

Emerging B2B sourcing trends emphasize agility and responsiveness. Suppliers who offer flexible minimum order quantities, quick turnaround times, and collaborative design services gain competitive advantage. Additionally, technology integration—such as 3D garment visualization and AI-driven inventory forecasting—is enhancing supply chain efficiency, reducing lead times, and minimizing overstock risks. This is particularly valuable for buyers operating within diverse economic environments where consumer preferences can shift rapidly.

Furthermore, the empire waist wedding dress sector is witnessing growth in demand for inclusive sizing and gender-neutral options, reflecting broader social movements that influence purchase decisions globally. Buyers aiming to capture niche segments must prioritize partnerships with manufacturers skilled in delivering these specialized offerings without compromising quality or style.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a critical consideration for B2B buyers in the empire waist wedding dress sector as environmental concerns and consumer awareness intensify worldwide. The bridal fashion industry traditionally faces scrutiny for high resource consumption and waste generation, making the adoption of green practices essential for long-term market viability.

International buyers sourcing empire waist gowns should prioritize suppliers committed to ethical production standards, including fair labor practices and transparent supply chains. Certifications such as Global Organic Textile Standard (GOTS), OEKO-TEX, and Fair Trade provide credible assurances that materials and manufacturing processes meet rigorous environmental and social criteria. These certifications are increasingly valued in Europe and among discerning buyers in South America and Africa, where regulatory frameworks and consumer activism push for greater corporate responsibility.

Material selection plays a pivotal role in sustainability. Eco-friendly fabrics like organic cotton, bamboo blends, and recycled polyester offer lower environmental footprints while maintaining the delicate drape and comfort essential to the empire waist silhouette. Additionally, sourcing natural dyes and avoiding hazardous chemicals aligns with global efforts to reduce pollution and protect worker health.

Circular economy principles are gaining traction, with some manufacturers offering take-back programs, garment recycling, or upcycling services tailored for wedding attire. Buyers can leverage these initiatives to differentiate their product lines and appeal to environmentally conscious bridal retailers.

Incorporating sustainability not only mitigates reputational risks but also enhances supply chain resilience by fostering long-term partnerships with responsible manufacturers. For B2B buyers, embedding environmental and ethical criteria into sourcing strategies is a forward-looking approach that aligns with evolving market expectations across Africa, the Middle East, South America, and Europe.

Brief Evolution and Historical Context

The empire waist silhouette originated in the early 19th century during the Regency era, gaining prominence through fashion icons such as Empress Joséphine of France. Its design—highlighting a raised waistline just below the bust—offered a graceful alternative to the structured corsetry of the time, emphasizing a natural, flowing form that symbolized elegance and simplicity.

For modern B2B buyers, understanding this historical lineage enriches product storytelling and marketing strategies, particularly in markets where heritage and craftsmanship are highly valued, such as Europe and parts of the Middle East. The timeless appeal of the empire waist also allows manufacturers and retailers to position their collections within a classic yet contemporary framework, appealing to brides seeking both tradition and modernity.

This enduring style’s adaptability across cultural contexts and decades underscores its commercial potential, making it a strategic focus for international sourcing and product development within the wedding dress sector.

Related Video: Crude Oil Prices & Global Trade Market Seen Stabilising After Trump Announced Iran Israel Ceasefire

Frequently Asked Questions (FAQs) for B2B Buyers of empire waist wedding dress

-

How can I effectively vet suppliers of empire waist wedding dresses from diverse international markets like Africa, South America, the Middle East, and Europe?

Supplier vetting should begin with verifying business licenses and certifications relevant to textile and apparel manufacturing. Request product samples to assess craftsmanship and fabric quality, focusing on the distinctive empire waist silhouette. Utilize third-party inspection services and check references or trade reviews, especially from buyers in your region. Engage suppliers with transparent communication and inquire about their production capacity, experience with international orders, and compliance with local export regulations to mitigate risks associated with cross-border transactions. -

Is customization of empire waist wedding dresses feasible, and how should I approach it when dealing with international suppliers?

Customization is widely offered, including adjustments in fabric type, neckline, sleeve style, and skirt volume to meet diverse market preferences. Clearly communicate your design specifications, target customer demographics, and cultural nuances, such as modesty preferences common in Middle Eastern markets. Request digital sketches or prototypes before bulk production. Negotiate minimum order quantities (MOQs) for customized styles, as bespoke options may require higher MOQs. Establish detailed contracts specifying customization parameters to ensure supplier accountability. -

What are typical minimum order quantities (MOQs) and lead times for empire waist wedding dresses from international suppliers, and how can I optimize these for my business?

MOQs vary significantly by supplier and region, typically ranging from 50 to 200 pieces per style. Lead times depend on production complexity and order size, commonly spanning 60 to 120 days. To optimize, consolidate orders with multiple styles to meet MOQ thresholds without overstocking a single design. Plan procurement schedules well ahead of peak wedding seasons in your target markets. Negotiate partial shipments to maintain cash flow and market responsiveness. Building strong relationships with suppliers may yield flexibility on MOQs and expedited production.

-

What payment terms and methods are most secure and efficient for international B2B transactions in empire waist wedding dress sourcing?

Common payment terms include 30-50% deposit upfront and balance upon shipment or after quality inspection. Letters of credit (LC) and escrow services provide added security by protecting both buyer and supplier interests. International wire transfers (T/T) are standard but verify counterparties carefully to avoid fraud. For new suppliers, consider smaller trial orders with payment on delivery. Use trade finance solutions like supplier credit or factoring to improve cash flow, especially when dealing with extended lead times and large order values. -

Which quality assurance (QA) processes and certifications should I require from suppliers to ensure consistent quality of empire waist wedding dresses?

Request adherence to international quality standards such as ISO 9001 for manufacturing processes and OEKO-TEX certification for textile safety, especially important for sensitive skin concerns. Implement pre-shipment inspections covering fabric quality, stitching, fit accuracy, and embellishment durability. Demand detailed QA reports and photographic evidence during production milestones. Establish clear rejection criteria and return policies in contracts. Regular audits or factory visits (virtual or physical) help maintain compliance and build trust over time. -

How can I manage logistics and shipping challenges when importing empire waist wedding dresses from multiple continents?

Engage experienced freight forwarders familiar with apparel exports and customs regulations in your destination country. Optimize shipping methods by balancing cost and delivery speed—sea freight is cost-effective for bulk but slower; air freight suits urgent or smaller shipments. Ensure all documentation, including commercial invoices, packing lists, and certificates of origin, comply with import regulations to avoid delays. Consolidate shipments to reduce costs and use warehouse services near ports for smoother distribution. Monitor shipments with tracking tools and plan for seasonal customs surges. -

What strategies should I adopt to handle disputes or quality issues with international empire waist wedding dress suppliers?

Prevent disputes by establishing clear, detailed contracts covering product specifications, timelines, payment terms, and penalties. Use written communication for all agreements and changes. In case of quality issues, request replacement or refunds supported by inspection reports and photos. Leverage third-party mediation or arbitration clauses in contracts to resolve conflicts amicably. Maintain ongoing communication to foster mutual understanding. Building long-term partnerships with transparent expectations reduces the frequency and severity of disputes. -

How do cultural and regional preferences impact the sourcing and design of empire waist wedding dresses for markets like Egypt, Spain, or Brazil?

Cultural sensitivities influence dress features such as sleeve length, neckline modesty, and embellishment styles. For example, Middle Eastern markets often prefer more coverage and intricate embroidery, while European buyers may favor minimalist elegance. South American markets might seek vibrant fabrics and dramatic skirts. Collaborate with suppliers to offer region-specific collections or customizable options. Incorporate local bridal trends and climate considerations into material selection. Understanding these nuances enhances market acceptance and competitive advantage in diverse B2B contexts.

Strategic Sourcing Conclusion and Outlook for empire waist wedding dress

Strategic sourcing of empire waist wedding dresses offers international B2B buyers a unique opportunity to capitalize on a timeless and versatile bridal silhouette that resonates across diverse markets. This style’s appeal lies in its flattering fit, adaptability in design variations, and broad cultural acceptance—making it a valuable addition to any bridal collection targeting customers from Africa, South America, the Middle East, and Europe.

Key B2B takeaways include:

- Supplier diversification: Engage with manufacturers who specialize in customizable empire waist gowns, allowing for tailored fabric choices, embellishments, and regional sizing preferences.

- Quality and comfort balance: Prioritize sourcing from suppliers who emphasize both exquisite craftsmanship and wearer comfort, crucial for markets valuing modesty and elegance.

- Trend responsiveness: Keep abreast of evolving neckline, sleeve, and skirt style trends within empire waist dresses to meet the nuanced tastes of your target demographics.

- Efficient logistics: Develop streamlined supply chains to manage lead times and import regulations, particularly for buyers in Egypt, Spain, and similar regions.

Looking ahead, strategic sourcing should leverage digital platforms and direct manufacturer partnerships to reduce costs and enhance customization capabilities. International buyers are encouraged to adopt a proactive sourcing strategy—focusing on quality, cultural relevance, and innovation—to strengthen their competitive positioning in the global bridal market. Embracing these insights will not only drive business growth but also ensure long-term resilience in an evolving industry landscape.