Master Sourcing High-Quality Prisma Dressing for Optimal

Introduction: Navigating the Global Market for prisma dressing

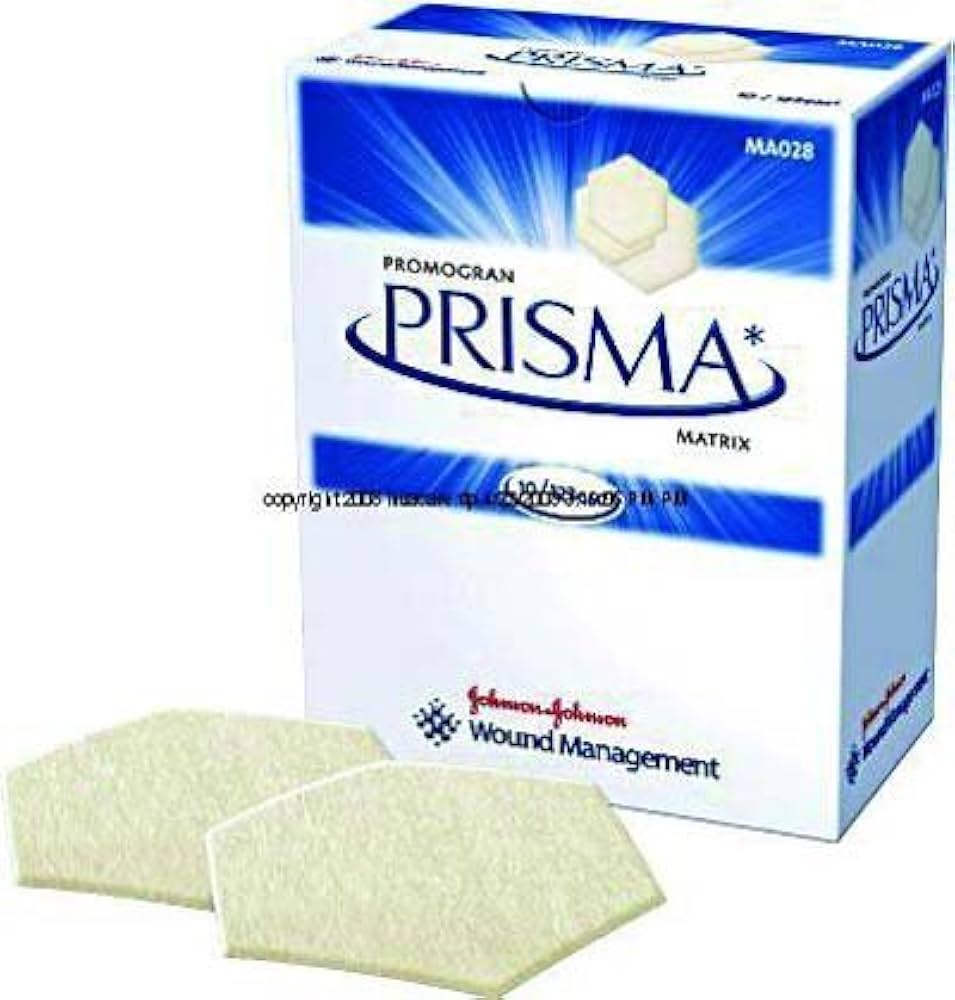

In an increasingly interconnected world, the demand for advanced wound care solutions is surging, making prisma dressing a pivotal product for healthcare providers and suppliers alike. This innovative dressing, known for its unique composition of collagen, ORC (oxidized regenerated cellulose), and silver, plays a critical role in promoting healing and preventing infection in chronic and acute wounds. As international B2B buyers from regions such as Africa, South America, the Middle East, and Europe (including markets like Mexico and the UK) seek reliable and effective wound care solutions, understanding the nuances of prisma dressing becomes essential.

This comprehensive guide aims to empower buyers with actionable insights into the global market for prisma dressing. It covers a wide array of topics including the different types of dressings available, the materials used in their composition, manufacturing processes, quality control standards, and leading suppliers in the market. Additionally, it delves into cost considerations and provides answers to frequently asked questions, equipping buyers with the knowledge necessary for informed sourcing decisions.

By leveraging this guide, international B2B buyers can navigate the complexities of the prisma dressing market, ensuring they select products that meet the specific needs of their healthcare environments. Understanding these elements not only enhances procurement strategies but also contributes to better patient outcomes, making the choice of prisma dressing a crucial investment in quality care.

Understanding prisma dressing Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| 3M™ Promogran Prisma™ | Collagen matrix with ORC and silver, promotes moist wound healing | Chronic wounds, diabetic ulcers | Pros: Effective for granulation; antimicrobial properties. Cons: Higher cost compared to traditional dressings. |

| Hydrocolloid Prisma Dressing | Gel-forming, moisture-retentive, provides cushioning | Pressure ulcers, surgical wounds | Pros: Comfortable; adheres well; minimizes pain on removal. Cons: Can macerate surrounding skin if not changed regularly. |

| Foam Prisma Dressing | Absorbent, non-adherent, offers thermal insulation | Moderate to heavily exudating wounds | Pros: Highly absorbent; protects from external contaminants. Cons: May require frequent changes in high-exudate scenarios. |

| Alginate Prisma Dressing | Derived from seaweed, highly absorbent, promotes hemostasis | Venous ulcers, cavity wounds | Pros: Excellent for exudate management; biodegradable. Cons: Requires secondary dressing; may be less suitable for dry wounds. |

| Transparent Film Prisma Dressing | Thin, flexible, waterproof, allows for visualization of the wound | IV sites, superficial wounds | Pros: Easy to apply; allows monitoring without removal. Cons: Limited absorption; not suitable for heavily exudating wounds. |

3M™ Promogran Prisma™

This dressing combines collagen with oxidized regenerated cellulose (ORC) and silver, creating a matrix that enhances moist wound healing. It’s particularly effective for chronic wounds and diabetic ulcers, making it a preferred choice for healthcare facilities focused on advanced wound care. When purchasing, consider the balance between its higher cost and its benefits, including antimicrobial properties and promotion of granulation tissue.

Hydrocolloid Prisma Dressing

Hydrocolloid dressings are known for their gel-forming abilities, creating a moist environment that is conducive to wound healing. They are ideal for pressure ulcers and surgical wounds. Buyers should evaluate the comfort and adherence of these dressings, as they can minimize pain during removal. However, it’s essential to monitor the surrounding skin to prevent maceration, which can occur if the dressing is left on too long.

Foam Prisma Dressing

Foam dressings are particularly suitable for moderate to heavily exudating wounds due to their absorbent nature. They provide thermal insulation and protect the wound from external contaminants. For B2B buyers, the key consideration is the frequency of dressing changes, which may increase in high-exudate situations. While they offer excellent protection, ensuring the right balance of absorbency and wear time is crucial.

Alginate Prisma Dressing

Derived from seaweed, alginate dressings are highly absorbent and promote hemostasis, making them suitable for venous ulcers and cavity wounds. Their biodegradable nature is appealing for environmentally conscious buyers. However, alginates require a secondary dressing for optimal performance and may not be suitable for dry wounds. B2B purchasers should consider the need for additional materials when selecting this type.

Transparent Film Prisma Dressing

These dressings are thin, flexible, and waterproof, allowing for easy monitoring of the wound without removal. They are commonly used for IV sites and superficial wounds. Buyers should be aware that while they are easy to apply and provide a barrier to moisture, their limited absorption capacity makes them unsuitable for heavily exudating wounds. This aspect should be carefully considered in the context of the specific wound care needs of patients.

Related Video: Lecture 1 Two compartment models

Key Industrial Applications of prisma dressing

| Industry/Sector | Specific Application of prisma dressing | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Healthcare | Advanced wound care in hospitals | Reduces healing time, minimizes infection risk | Ensure compliance with local regulations and standards |

| Long-term Care Facilities | Management of chronic wounds in elderly patients | Enhances patient comfort, reduces overall care costs | Evaluate product availability and training for staff |

| Home Healthcare | Wound care for homebound patients | Facilitates self-care, improves patient outcomes | Consider ease of use and patient education materials |

| Sports Medicine | Treatment of sports injuries and post-surgical care | Accelerates recovery, supports tissue regeneration | Assess product versatility and compatibility with other treatments |

| Veterinary Medicine | Wound management in animals | Improves healing rates, reduces risk of complications | Look for specialized formulations for different species |

Healthcare

In hospitals, prisma dressing is utilized for advanced wound care, particularly for patients with complex or chronic wounds. The dressing’s collagen matrix and antimicrobial properties help to accelerate healing and reduce the risk of infection, critical in high-stakes healthcare environments. For international buyers, especially from regions like Africa and South America, it is essential to ensure that the dressing complies with local health regulations and standards to guarantee patient safety and efficacy.

Long-term Care Facilities

In long-term care settings, such as nursing homes, prisma dressing is effective for managing chronic wounds common among elderly patients. Its ability to promote healing while providing comfort can significantly enhance the quality of care and reduce overall healthcare costs. Buyers in this sector should evaluate the product’s availability, as well as the need for staff training on its application to maximize its benefits.

Home Healthcare

For home healthcare providers, prisma dressing offers an ideal solution for wound care among homebound patients. The dressing facilitates self-care, empowering patients to manage their wounds effectively while minimizing the need for frequent medical visits. Buyers must consider the ease of use and the availability of patient education materials to ensure proper application and adherence, particularly in diverse markets like the Middle East and Europe.

Sports Medicine

In the realm of sports medicine, prisma dressing is employed for treating sports injuries and aiding in post-surgical recovery. Its regenerative properties support faster healing, which is crucial for athletes looking to return to their activities promptly. Buyers should assess the product’s versatility and its compatibility with other treatments to ensure comprehensive care for athletes across various sports disciplines.

Veterinary Medicine

Prisma dressing also finds applications in veterinary medicine, particularly for wound management in animals. Its unique formulation enhances healing rates and reduces the risk of complications, making it a valuable asset for veterinarians. When sourcing for this application, buyers should look for specialized formulations tailored for different animal species, ensuring that the product meets specific veterinary standards and requirements.

Related Video: Promogran Prisma : How and when to use

Strategic Material Selection Guide for prisma dressing

When selecting materials for prisma dressings, it is essential to consider their properties, advantages, disadvantages, and suitability for specific applications. Below is an analysis of four common materials used in prisma dressings, focusing on their performance characteristics and implications for international B2B buyers.

1. Collagen

Key Properties: Collagen is a natural protein that provides excellent biocompatibility and promotes cellular activities essential for wound healing. It has a temperature resistance up to 60°C and maintains structural integrity under physiological conditions.

Pros & Cons: Collagen dressings are durable and support moisture retention, which is critical for optimal healing. However, they can be relatively expensive and may require complex manufacturing processes to ensure purity and effectiveness. The sourcing of high-quality collagen can also be a challenge, impacting availability and cost.

Impact on Application: Collagen is particularly effective for chronic wounds and ulcers due to its ability to enhance granulation tissue formation. It is compatible with various wound exudates, promoting a moist healing environment.

Considerations for International Buyers: Buyers should ensure compliance with local regulations regarding animal-derived materials. Standards such as ASTM and ISO for biocompatibility should be verified, especially in regions with strict import regulations like the EU.

2. Silver

Key Properties: Silver has inherent antimicrobial properties, making it effective in preventing infection in wounds. It can withstand temperatures up to 70°C and is resistant to corrosion, ensuring longevity in various environments.

Pros & Cons: The primary advantage of silver dressings is their ability to reduce bacterial load, which is crucial for infected wounds. However, they can be more costly than standard dressings and may lead to argyria (skin discoloration) with prolonged use.

Impact on Application: Silver dressings are ideal for acute and chronic wounds at risk of infection. They can be used in conjunction with other materials to enhance their effectiveness.

Considerations for International Buyers: Compliance with antimicrobial standards (e.g., ISO 10993) is essential. Buyers in regions like Africa and South America should consider the availability of silver dressings and their cost-effectiveness in local markets.

3. Alginate

Key Properties: Derived from seaweed, alginate is highly absorbent and forms a gel-like substance when in contact with wound exudate. It can handle moderate to heavy exudate and maintains its integrity at temperatures up to 50°C.

Pros & Cons: Alginate dressings are cost-effective and easy to apply, making them suitable for various wound types. However, they may not be suitable for dry wounds and can be less durable compared to collagen or silver dressings.

Impact on Application: Alginate is particularly effective for wounds with high exudate levels, such as venous ulcers. It promotes a moist environment that facilitates healing.

Considerations for International Buyers: Buyers should be aware of sourcing challenges in regions where alginate is not readily available. Compliance with local standards for biocompatibility and performance is crucial for market acceptance.

4. Hydrocolloid

Key Properties: Hydrocolloid dressings are made from a combination of materials that form a gel when in contact with moisture. They are resistant to water and can withstand temperatures up to 60°C.

Pros & Cons: These dressings are versatile and can be used for various wound types, providing a moist healing environment. However, they can be less effective in managing heavy exudate and may require more frequent changes.

Impact on Application: Hydrocolloids are suitable for superficial wounds and can be used in both acute and chronic settings. They help in pain management by providing a cushioning effect.

Considerations for International Buyers: Buyers should ensure that hydrocolloid products meet local health regulations and standards. In regions like Europe, adherence to CE marking requirements is vital for market entry.

Summary Table

| Material | Typical Use Case for prisma dressing | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Collagen | Chronic wounds and ulcers | Excellent biocompatibility | High cost and sourcing challenges | High |

| Silver | Infected wounds | Antimicrobial properties | Potential for skin discoloration | High |

| Alginate | Moderate to heavy exudate wounds | Highly absorbent | Not suitable for dry wounds | Medium |

| Hydrocolloid | Superficial and chronic wounds | Versatile and pain management | Less effective for heavy exudate | Medium |

This guide provides insights into the material selection process for prisma dressings, enabling international B2B buyers to make informed decisions based on their specific market needs and regulatory environments.

In-depth Look: Manufacturing Processes and Quality Assurance for prisma dressing

Manufacturing Processes for Prisma Dressing

The manufacturing of Prisma dressings, specifically the 3M™ Promogran Prisma™ Matrix Wound Dressing, involves several critical stages designed to ensure the highest quality and efficacy of the product. Understanding these processes is essential for B2B buyers, as it allows them to assess supplier capabilities and reliability.

1. Material Preparation

The first stage in manufacturing Prisma dressings is material preparation. This involves sourcing high-quality raw materials, including collagen, oxidized regenerated cellulose (ORC), and silver. Each material must meet stringent specifications to ensure biocompatibility and effectiveness in wound healing.

- Sourcing Standards: Suppliers should adhere to international standards such as ISO 13485, which focuses on the quality management systems for medical devices.

- Material Inspection: Incoming materials undergo rigorous inspection (Incoming Quality Control – IQC) to confirm they meet defined quality parameters before proceeding to the next stage.

2. Forming

After material preparation, the next step is forming the dressing. This involves combining the materials into a cohesive structure that meets the intended design specifications.

- Techniques Used:

- Casting: This method allows for the uniform distribution of collagen and ORC, ensuring consistent performance across the dressing.

- Layering: Silver ions may be incorporated in layers to enhance antimicrobial properties, crucial for infection control in wound management.

3. Assembly

The assembly stage integrates the formed dressing with any additional components necessary for its functionality. This may include backing materials or adhesive layers.

- Automated Processes: Many manufacturers utilize automated systems to minimize human error and enhance precision during assembly.

- Quality Checks: Inline Process Quality Control (IPQC) is implemented at this stage to monitor parameters such as thickness and adhesion strength to ensure compliance with product specifications.

4. Finishing

Finishing processes prepare the dressing for packaging and distribution. This includes sterilization, which is vital for ensuring the product’s safety for use in clinical settings.

- Sterilization Methods: Common techniques include ethylene oxide (EtO) and gamma radiation, both of which are effective in eliminating microbial contamination without compromising the product’s integrity.

- Final Quality Inspection: Final Quality Control (FQC) checks confirm that the finished product meets all regulatory and performance standards before packaging.

Quality Assurance for Prisma Dressing

Quality assurance (QA) is critical in the manufacturing of Prisma dressings. It not only ensures compliance with regulatory requirements but also guarantees product safety and effectiveness.

International Standards

B2B buyers should be aware of various international and industry-specific standards that govern the quality of medical devices, including:

- ISO 9001: This standard focuses on quality management systems, ensuring that manufacturers consistently meet customer and regulatory requirements.

- ISO 13485: Specifically tailored for medical devices, this standard outlines requirements for a comprehensive quality management system, including documentation, risk management, and continuous improvement.

- CE Marking: For products sold in Europe, CE marking indicates compliance with health, safety, and environmental protection standards.

Quality Control Checkpoints

Quality control checkpoints are integral to maintaining product integrity throughout the manufacturing process:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon receipt to verify compliance with specifications.

- In-process Quality Control (IPQC): Ongoing monitoring during production helps identify issues in real-time, ensuring that any deviations are addressed immediately.

- Final Quality Control (FQC): This final inspection ensures that the finished product meets all specifications before shipping.

Common Testing Methods

Testing methods used in the quality assurance of Prisma dressings include:

- Physical Testing: Assessing properties such as tensile strength, elongation, and moisture retention.

- Microbial Testing: Evaluating the antimicrobial efficacy of silver within the dressing against specific pathogens.

- Biocompatibility Testing: Ensuring that the materials used do not provoke adverse reactions when in contact with human tissue.

Verifying Supplier Quality Control

International B2B buyers must conduct due diligence when selecting suppliers for Prisma dressings. Here are several actionable steps:

- Supplier Audits: Conducting on-site audits of potential suppliers can provide insights into their manufacturing processes and quality assurance practices. Look for evidence of compliance with ISO standards and other relevant regulations.

- Reviewing Quality Reports: Requesting detailed quality assurance reports, including IQC, IPQC, and FQC data, helps verify that suppliers maintain high standards throughout production.

- Third-Party Inspections: Engaging third-party organizations to assess supplier facilities and processes can provide an unbiased view of their capabilities and compliance with international standards.

Quality Control Nuances for International Buyers

B2B buyers from Africa, South America, the Middle East, and Europe should be aware of specific nuances related to quality control and regulatory compliance:

- Regulatory Variances: Different regions may have varying regulatory requirements. For example, while CE marking is essential in Europe, other regions may have different certifications.

- Cultural Considerations: Understanding cultural nuances in business practices and communication can facilitate smoother negotiations and partnerships with suppliers.

- Logistical Challenges: Buyers should consider the logistical aspects of sourcing products internationally, including shipping times, customs regulations, and potential tariffs that may affect overall costs.

By understanding the manufacturing processes and quality assurance measures for Prisma dressings, international B2B buyers can make informed decisions that ensure they source high-quality, effective wound care products.

Related Video: Amazing Garment Manufacturing Process from Fabric to Finished Product Inside the Factory

Comprehensive Cost and Pricing Analysis for prisma dressing Sourcing

Cost Structure of Prisma Dressing

When sourcing prisma dressings, understanding the cost components is crucial for international B2B buyers. The main elements contributing to the overall cost include:

- Materials: The primary component, including collagen, ORC (oxidized regenerated cellulose), and silver, which can vary significantly based on quality and supplier.

- Labor: Costs associated with the workforce involved in manufacturing and quality control. Labor rates can differ based on geographic location.

- Manufacturing Overhead: This includes utilities, facility maintenance, and equipment depreciation, which contribute to the cost of production.

- Tooling: Initial setup costs for production lines, particularly if custom specifications are required.

- Quality Control (QC): Investment in testing and certification processes to ensure compliance with international standards.

- Logistics: Shipping costs, including freight, insurance, and handling, which are particularly significant for international buyers.

- Margin: The profit margin added by manufacturers or distributors, which can fluctuate based on market demand and competition.

Influencers on Pricing

Several factors can significantly impact the pricing of prisma dressings:

- Volume/MOQ (Minimum Order Quantity): Bulk purchases often lead to discounts, making it essential to assess your demand accurately.

- Specifications and Customization: Custom features or enhanced specifications can increase costs. Buyers should clarify their needs early in discussions with suppliers.

- Material Quality and Certifications: Higher quality materials and certifications (e.g., CE marking, ISO standards) can elevate prices but often justify the cost through improved performance.

- Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge more due to their proven track record.

- Incoterms: Understanding shipping terms is vital. Costs can vary significantly based on whether the buyer or seller is responsible for shipping, insurance, and duties.

Buyer Tips for Cost Efficiency

To optimize sourcing strategies, international buyers should consider the following:

- Negotiate Terms: Engage in discussions about pricing, payment terms, and delivery schedules. Suppliers may offer flexibility for long-term partnerships or bulk orders.

- Evaluate Total Cost of Ownership (TCO): Look beyond the purchase price. Consider factors like shipping costs, storage, and potential wastage due to expiration. A higher upfront cost may result in lower overall expenses.

- Understand Pricing Nuances: Be aware of regional price variations. For example, prices may differ between Europe and Africa due to local market conditions and logistics costs.

- Research Market Trends: Staying informed about market trends can provide leverage during negotiations. For example, if material costs are rising, suppliers may be more willing to negotiate before prices increase further.

- Build Relationships: Establishing strong relationships with suppliers can lead to better pricing, priority in production, and favorable terms.

Conclusion

While sourcing prisma dressings, a comprehensive understanding of the cost structure and pricing influencers can empower international buyers, particularly from Africa, South America, the Middle East, and Europe. By strategically negotiating and evaluating the total cost of ownership, buyers can achieve significant cost efficiencies.

Disclaimer: Pricing for prisma dressings can fluctuate based on market conditions, material costs, and supplier capabilities. It is advisable to conduct thorough market research and obtain multiple quotes to ensure the best possible deal.

Spotlight on Potential prisma dressing Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘prisma dressing’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for prisma dressing

Key Technical Properties of Prisma Dressing

Understanding the essential technical properties of prisma dressing is crucial for international B2B buyers, particularly in the healthcare sector. Here are several critical specifications to consider:

-

Material Composition

Prisma dressings typically consist of a collagen matrix combined with oxidized regenerated cellulose (ORC) and silver. The collagen promotes cellular regeneration, while ORC helps manage exudate and create a moist wound environment. Silver acts as an antimicrobial agent, reducing the risk of infection. This composition is vital for buyers to ensure they are procuring products that meet clinical efficacy standards. -

Absorption Capacity

Absorption capacity refers to the dressing’s ability to manage wound exudate. High absorption capacity is crucial for managing moderate to heavy exudating wounds, as it prevents maceration of surrounding tissue. B2B buyers should assess this property to match the dressing to the specific needs of their patient population or market demand. -

Biocompatibility

Biocompatibility indicates how well the dressing interacts with biological systems without eliciting an adverse reaction. It is essential for ensuring patient safety and compliance with medical device regulations. Buyers should verify that the dressing is biocompatible and meets international standards, particularly when sourcing from different regions. -

Sterilization Assurance

The ability to maintain sterility until use is critical in wound care products. Prisma dressings are typically sterilized using gamma radiation or ethylene oxide. Buyers need to confirm that the products are sterilized according to recognized standards to ensure patient safety and minimize infection risks. -

Shelf Life

Shelf life determines how long a dressing can be stored before it becomes ineffective or unsafe to use. A longer shelf life is advantageous for inventory management and reduces waste. Buyers should look for products with an adequate shelf life to align with their purchasing and distribution cycles. -

Moisture Vapor Transmission Rate (MVTR)

MVTR measures how well the dressing allows moisture vapor to escape while maintaining a moist environment for the wound. A balanced MVTR is essential for promoting healing while preventing excessive moisture buildup. Buyers should seek dressings with optimal MVTR values to ensure effective wound management.

Common Trade Terminology

Familiarity with industry jargon is crucial for effective communication and negotiation in the B2B landscape. Below are several common terms relevant to prisma dressing:

-

OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or products that are used in another company’s end product. In the context of medical supplies, buyers may work with OEMs to source customized dressing solutions tailored to their specific needs. -

MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for B2B buyers to optimize inventory levels and manage cash flow effectively. -

RFQ (Request for Quotation)

An RFQ is a document that a buyer sends to suppliers to request pricing and other details for a specific quantity of goods. Issuing an RFQ allows buyers to compare offers and negotiate better terms. -

Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms helps buyers understand shipping costs, risks, and responsibilities during the importation process. -

Regulatory Compliance

This term refers to the adherence to laws and regulations governing medical products. Buyers must ensure that the prisma dressings they procure comply with local and international regulations to avoid legal issues and ensure product safety.

By understanding these properties and terms, B2B buyers can make informed decisions when sourcing prisma dressing, ensuring they meet the needs of their healthcare clients while complying with industry standards.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the prisma dressing Sector

Market Overview & Key Trends

The global market for prisma dressings, particularly the 3M™ Promogran Prisma™, is experiencing significant growth driven by increasing awareness of advanced wound care solutions. Key factors include the rising prevalence of chronic wounds, such as diabetic ulcers and pressure sores, alongside an aging population. Moreover, the COVID-19 pandemic has heightened the demand for effective wound management solutions, influencing sourcing strategies across regions.

Illustrative Image (Source: Google Search)

International B2B buyers, especially from Africa, South America, the Middle East, and Europe, are witnessing a shift towards digital sourcing platforms that facilitate streamlined procurement processes. Emerging technologies such as AI-driven analytics and blockchain for supply chain transparency are becoming critical in decision-making. Companies are increasingly prioritizing suppliers who demonstrate reliability, quality assurance, and compliance with international standards.

In addition, sustainability is becoming a pivotal consideration. Buyers are seeking suppliers who can provide environmentally friendly products and practices, reflecting a broader global trend towards corporate social responsibility. This is particularly relevant in regions like Europe, where stringent regulations on medical products are in place, necessitating adherence to eco-friendly practices.

Sustainability & Ethical Sourcing in B2B

Sustainability in the prisma dressing sector encompasses both environmental impact and ethical sourcing. The production of medical dressings, including those with collagen and silver, can have significant ecological footprints, from raw material extraction to manufacturing processes. Buyers should prioritize suppliers who actively work to minimize waste and energy use in their production processes.

Ethical supply chains are increasingly crucial for B2B buyers. This includes ensuring fair labor practices and sourcing raw materials responsibly. Certifications such as ISO 14001 (Environmental Management) and FSC (Forest Stewardship Council) can serve as indicators of a supplier’s commitment to sustainability. Moreover, the use of biodegradable or recyclable materials in the production of dressings can enhance a company’s sustainability profile.

Incorporating green certifications into procurement criteria not only aligns with ethical practices but can also improve brand reputation and customer trust. B2B buyers are encouraged to conduct thorough due diligence on potential suppliers, verifying their sustainability claims and practices.

Brief Evolution/History

The prisma dressing sector has evolved significantly over the past few decades. Initially, wound care was dominated by traditional dressings that often lacked the necessary properties for effective healing. The introduction of advanced materials, such as collagen-based dressings, marked a turning point, allowing for better moisture retention and faster healing times.

The development of the 3M™ Promogran Prisma™, combining collagen, oxidized regenerated cellulose (ORC), and silver, exemplifies this evolution. It represents a shift towards multifunctional dressings that not only protect but also promote healing through antimicrobial properties. As the market continues to innovate, B2B buyers are advised to stay informed about emerging products and technologies that can enhance patient outcomes and operational efficiencies.

Related Video: Global Trade & Logistics – What is Global Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of prisma dressing

-

What should I consider when vetting suppliers for prisma dressing?

When vetting suppliers for prisma dressing, focus on their industry reputation, certifications, and experience in wound care products. Check if they comply with international quality standards such as ISO 13485 and have CE marking for European markets. Request references and case studies to understand their track record. Additionally, assess their production capabilities and ensure they can meet your specific requirements, including customization options. -

Can prisma dressings be customized to meet specific needs?

Yes, many manufacturers offer customization options for prisma dressings. This can include variations in size, shape, and additional features like antimicrobial properties or specific packaging requirements. Engage in discussions with suppliers early in the sourcing process to clarify your needs and understand their capabilities. Customization may involve additional costs and longer lead times, so plan accordingly. -

What are the typical minimum order quantities (MOQs) and lead times for prisma dressing?

Minimum order quantities for prisma dressings can vary widely depending on the supplier and customization requirements. Generally, MOQs range from 100 to 1,000 units. Lead times also depend on the order size and complexity, typically ranging from 2 to 8 weeks. Always confirm these details during negotiations to avoid delays in your supply chain and ensure timely delivery.

Illustrative Image (Source: Google Search)

-

What payment terms should I expect when sourcing prisma dressings?

Payment terms for prisma dressings can differ based on the supplier’s policies and your negotiation leverage. Common terms include advance payment, net 30, or net 60 days. For larger orders, consider discussing a letter of credit or escrow services to mitigate risks. Ensure that all terms are clearly outlined in your purchase agreement to avoid disputes later. -

How can I ensure the quality and certification of prisma dressings?

To ensure quality, request certifications from the supplier, including ISO certifications and compliance with regional regulations like CE marking for Europe or FDA approval in the U.S. Ask for documentation of quality assurance processes and batch testing results. Conducting an on-site audit or requesting third-party testing can also provide additional assurance of product quality. -

What logistics considerations should I keep in mind when importing prisma dressing?

Logistics for importing prisma dressings include understanding shipping regulations, customs duties, and transportation costs. Work with logistics providers experienced in medical supplies to navigate international shipping requirements effectively. Ensure that all necessary documentation, such as import permits and commercial invoices, is prepared in advance to avoid delays at customs. -

How should I handle disputes with suppliers of prisma dressing?

In the event of a dispute with a supplier, first attempt to resolve the issue through direct communication. If this fails, refer to your contract’s dispute resolution clause, which may include mediation or arbitration. Keep detailed records of all communications and agreements to support your case. Establishing a clear contract with defined terms can also help prevent disputes from arising. -

What are the best practices for maintaining a long-term relationship with suppliers?

Building a long-term relationship with suppliers involves regular communication, timely payments, and constructive feedback. Schedule periodic reviews to discuss performance, quality issues, and any needed adjustments. Cultivating a collaborative approach can lead to better pricing, priority service, and access to new products. Show appreciation for their efforts, which can enhance loyalty and commitment.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for prisma dressing

As international B2B buyers navigate the complexities of sourcing Prisma dressing, it is essential to emphasize the strategic advantages of this advanced wound care solution. Prisma dressing, particularly the 3M™ Promogran Prisma™ variant, integrates collagen, oxidized regenerated cellulose (ORC), and silver, providing a multifaceted approach to wound healing. This combination not only promotes an optimal healing environment but also significantly reduces the risk of infection, making it a vital choice for healthcare providers across diverse markets.

Key Takeaways:

– Quality and Efficacy: Investing in high-quality wound dressings like Prisma can lead to better patient outcomes, reducing overall healthcare costs.

– Market Demand: Growing awareness of advanced wound care technologies in regions such as Africa, South America, the Middle East, and Europe opens up significant opportunities for B2B buyers.

– Supplier Relationships: Building strong partnerships with reputable suppliers ensures access to the latest innovations and reliable product support.

Looking ahead, the demand for effective wound management solutions will continue to rise. Buyers are encouraged to engage with suppliers who can offer comprehensive support and insight into product applications. By prioritizing strategic sourcing of Prisma dressing, organizations can enhance their service offerings and improve patient care across various healthcare settings.