Your Ultimate Guide to Sourcing Primapore Dressing

Introduction: Navigating the Global Market for primapore dressing

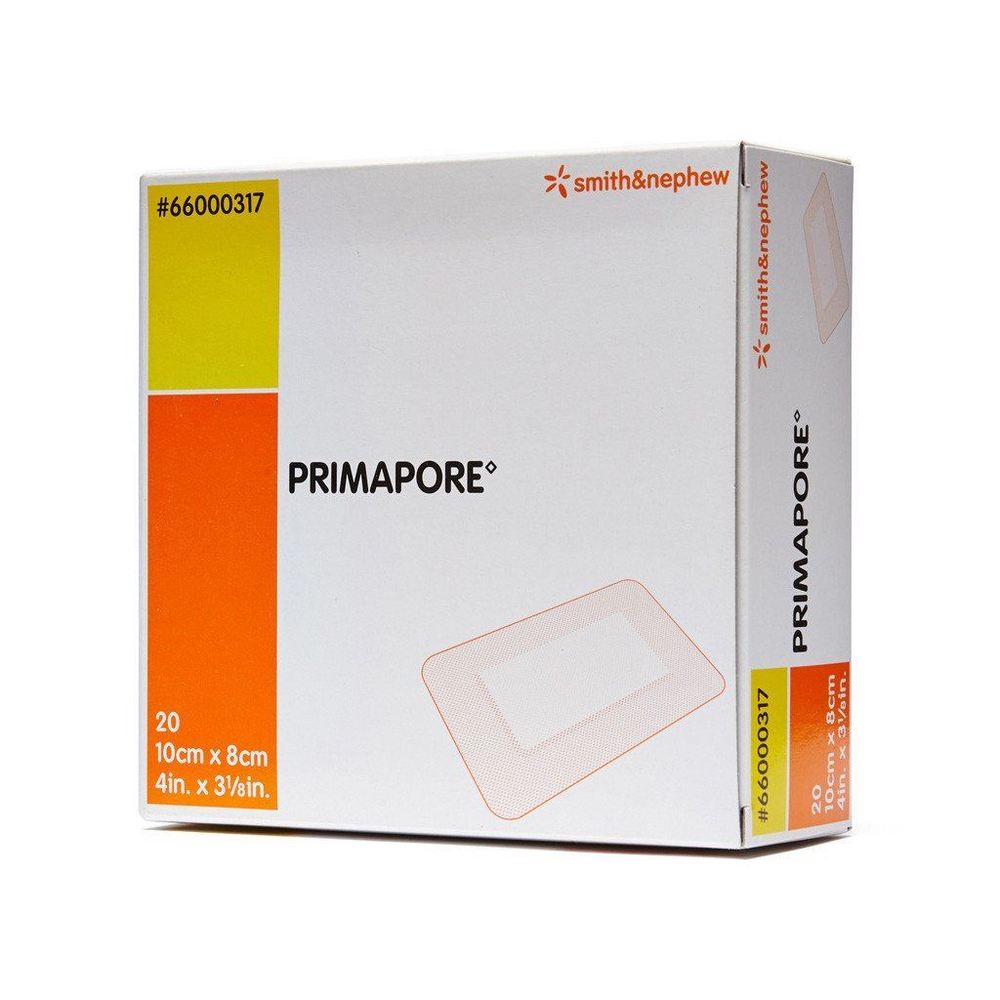

In the rapidly evolving landscape of medical supplies, Primapore dressings emerge as a pivotal solution in wound care management. Renowned for their blend of comfort, breathability, and efficacy, these adhesive non-woven dressings cater to a wide array of applications, from post-operative care to everyday wound management. For international B2B buyers, particularly those operating in Africa, South America, the Middle East, and Europe, understanding the nuances of Primapore dressings is essential for making informed sourcing decisions.

This comprehensive guide delves into the various types of Primapore dressings available, highlighting their materials, manufacturing standards, and quality control processes. It also provides insights into prominent suppliers, pricing strategies, and market trends, equipping buyers with the knowledge needed to navigate this critical segment of healthcare products effectively.

Additionally, we address frequently asked questions to demystify common concerns and facilitate smarter purchasing choices. By empowering buyers with actionable insights, this guide aims to enhance the procurement process, ensuring that organizations can secure the best possible products for their wound care needs. Whether you’re sourcing for hospitals, clinics, or home care settings, understanding Primapore dressings will significantly impact your ability to deliver optimal patient outcomes while maintaining cost efficiency.

Understanding primapore dressing Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Primapore Dressing | Non-woven fabric, breathable, low adherent | General wound care, post-operative wounds | Pros: Versatile, widely available. Cons: May not suit all skin types. |

| Water-Resistant Primapore Dressing | Moisture-proof, maintains integrity in water | Post-operative care, hygiene maintenance | Pros: Ideal for patients needing showering. Cons: Limited breathability. |

| Sensitive Skin Primapore Dressing | Hypoallergenic adhesive, soft material | Pediatric care, patients with sensitivities | Pros: Reduces irritation, comfortable. Cons: Higher cost than standard options. |

| Primapore for Sports Injuries | Durable, flexible, designed for movement | Athletic care, minor sports injuries | Pros: Supports active lifestyles, secure fit. Cons: May be bulkier for some users. |

| Primapore for Surgical Wounds | Enhanced absorbency, secure adhesion | Surgical sites, high-exudate wounds | Pros: Effective in exudate management. Cons: Requires careful application. |

Standard Primapore Dressing

The Standard Primapore Dressing is widely recognized for its versatility across various wound types, including minor cuts and post-operative care. Made from a breathable non-woven fabric, it features a low adherent layer that minimizes pain during dressing changes. For B2B buyers, the key purchasing consideration is the availability of various sizes to accommodate different wound dimensions. While this dressing is effective for most patients, it may not be suitable for those with sensitive skin, necessitating careful selection based on patient needs.

Water-Resistant Primapore Dressing

Designed to withstand moisture, the Water-Resistant Primapore Dressing is an excellent choice for post-operative care where hygiene is crucial. This dressing allows patients to shower without compromising the wound’s integrity, making it ideal for those recovering from surgery. B2B buyers should consider the specific needs of their patient population when selecting this type, as its limited breathability may not be suitable for all wounds. While it offers significant advantages for hygiene, it may not be the best option for wounds requiring high airflow.

Sensitive Skin Primapore Dressing

The Sensitive Skin Primapore Dressing is tailored for patients prone to allergic reactions or skin irritations. Utilizing hypoallergenic adhesives and a soft material, this dressing ensures comfort while providing effective wound protection. For B2B buyers, this option is particularly relevant in pediatric care or among populations with known sensitivities. The higher cost associated with these dressings is a consideration, but the benefits in patient comfort and reduced irritation can justify the investment.

Primapore for Sports Injuries

Primapore dressings designed for sports injuries are crafted to be durable and flexible, accommodating the active lifestyles of athletes. These dressings provide reliable support for minor injuries while ensuring that they stay in place during physical activities. B2B buyers in the sports medicine or rehabilitation sectors should assess the fit and flexibility of these dressings, as they may be bulkier than traditional options. While they offer excellent protection for active individuals, their thickness could be a drawback for some users seeking discreet solutions.

Primapore for Surgical Wounds

The Primapore for Surgical Wounds features enhanced absorbency and secure adhesion, making it ideal for managing surgical sites and high-exudate wounds. This dressing is particularly beneficial in hospital settings where infection prevention and wound healing are critical. B2B buyers should focus on the specific absorbency needs of their patients when selecting this type. While it excels in managing exudate, careful application is necessary to ensure optimal performance, which may require additional training for staff.

Related Video: Lecture 1 Two compartment models

Key Industrial Applications of primapore dressing

| Industry/Sector | Specific Application of Primapore Dressing | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Healthcare | Post-operative wound care | Reduces infection risk and promotes faster healing | Ensure compliance with local medical regulations |

| Sports & Fitness | Management of sports-related injuries | Provides protection while allowing mobility for athletes | Consider durability and breathability for active use |

| Home Healthcare | Wound care for elderly or disabled patients | Enhances comfort and ease of use for caregivers | Look for hypoallergenic options for sensitive skin |

| Pediatric Care | Treatment of minor injuries in children | Minimizes pain during dressing changes | Focus on soft, flexible materials for comfort |

| Industrial Safety | First aid for workplace injuries | Quick application reduces downtime and enhances safety | Evaluate bulk purchasing options for cost efficiency |

Healthcare: Post-operative Wound Care

In the healthcare sector, Primapore dressings are extensively used for post-operative wound management. They provide a breathable environment that promotes healing while absorbing exudate, thereby minimizing the risk of infection. For international buyers, especially in regions like Africa and South America, sourcing must consider local medical regulations and the availability of different sizes to cater to various surgical procedures. Ensuring that the dressings are compliant with health standards will also enhance patient safety and outcomes.

Sports & Fitness: Management of Sports-related Injuries

In the sports and fitness industry, Primapore dressings are ideal for treating cuts and abrasions sustained during physical activities. Their breathable and flexible nature allows athletes to remain active while ensuring that injuries are protected. Buyers in this sector should prioritize sourcing durable dressings that can withstand physical activity and offer moisture resistance. This is particularly relevant in regions with high humidity, such as parts of the Middle East, where moisture can compromise wound care.

Illustrative Image (Source: Google Search)

Home Healthcare: Wound Care for Elderly or Disabled Patients

For home healthcare providers, Primapore dressings offer a practical solution for managing wounds in elderly or disabled patients. Their design minimizes discomfort during dressing changes, which is crucial for patients with sensitive skin. When sourcing these products, it’s essential to consider hypoallergenic options that cater to vulnerable populations. This is especially important in European markets where regulatory standards for healthcare products are stringent.

Pediatric Care: Treatment of Minor Injuries in Children

In pediatric care, Primapore dressings are particularly beneficial due to their soft and flexible materials, which help to minimize pain during application and removal. They are suitable for treating minor injuries in children, making them a preferred choice for parents and healthcare providers alike. Buyers should focus on sourcing options specifically designed for sensitive skin, ensuring that they meet safety standards applicable in their respective countries.

Industrial Safety: First Aid for Workplace Injuries

In industrial settings, Primapore dressings are utilized as part of first aid kits to manage workplace injuries promptly. Their ease of application and effectiveness in protecting wounds can significantly reduce downtime caused by injuries. For B2B buyers in this sector, evaluating bulk purchasing options can lead to cost savings and ensure that adequate supplies are always on hand. Additionally, sourcing from reputable suppliers who meet occupational safety regulations is vital for compliance and employee safety.

Related Video: Smith and Nephew Primapore Wound Dressing

Strategic Material Selection Guide for primapore dressing

When selecting materials for Primapore dressings, it’s essential to consider their properties, advantages, and limitations. This analysis focuses on four common materials used in Primapore dressings: non-woven fabric, adhesive layers, absorbent pads, and water-resistant coatings. Each material plays a crucial role in the performance and suitability of the dressing for various applications.

Non-Woven Fabric

Key Properties: Non-woven fabrics are characterized by their breathability and flexibility, making them ideal for wound management. They can withstand moderate temperatures and pressures, ensuring comfort and protection.

Pros & Cons: The primary advantage of non-woven fabric is its softness and low adherence, which minimizes pain during dressing changes. However, they may not be as durable as woven fabrics and can be more susceptible to tearing under high stress.

Impact on Application: Non-woven fabrics are compatible with a wide range of wounds, including post-operative sites and minor abrasions. Their breathability helps prevent moisture buildup, which is crucial for healing.

Considerations for International Buyers: Compliance with international standards such as ASTM and ISO is vital. Buyers from regions like Africa and South America should ensure that the non-woven materials used are hypoallergenic and suitable for local climates.

Adhesive Layers

Key Properties: Adhesive layers are designed to provide secure adhesion while being gentle on the skin. They must exhibit strong initial tack and consistent performance under varying temperatures and humidity levels.

Pros & Cons: The main advantage of high-quality adhesives is their ability to keep the dressing securely in place, reducing the need for frequent replacements. However, some adhesives can cause skin irritation, particularly in sensitive populations.

Impact on Application: The choice of adhesive can significantly impact the dressing’s usability in humid conditions, making it essential for tropical regions. Adhesives that maintain performance in high moisture environments are particularly beneficial.

Considerations for International Buyers: Buyers should look for adhesives that comply with local regulations and standards, such as the European Medical Device Regulation (MDR). In regions with diverse skin types, hypoallergenic options are preferred.

Absorbent Pads

Key Properties: Absorbent pads are designed to manage exudate effectively, featuring materials that can absorb moisture without compromising breathability.

Pros & Cons: The key advantage of absorbent pads is their ability to reduce the risk of maceration around the wound. However, they can increase the overall cost of the dressing, especially if advanced materials are used.

Impact on Application: These pads are crucial for managing wounds with high exudate levels, making them suitable for post-operative care and chronic wounds. Their performance can vary based on the wound type and location.

Considerations for International Buyers: Understanding the local market’s needs is essential. For instance, in regions with high humidity, absorbent pads that can handle moisture without losing integrity are vital.

Water-Resistant Coatings

Key Properties: Water-resistant coatings provide an additional layer of protection against moisture, ensuring that the dressing remains intact during exposure to water.

Pros & Cons: The primary advantage is enhanced durability and the ability to maintain hygiene during activities like showering. However, these coatings can sometimes limit breathability, which may affect wound healing.

Impact on Application: Water-resistant dressings are particularly beneficial for patients who require hygiene maintenance without compromising wound integrity. This is crucial in post-operative care where exposure to moisture can lead to complications.

Considerations for International Buyers: Buyers should ensure that water-resistant materials meet local and international standards for medical devices. In regions with varying climate conditions, the effectiveness of these coatings can be a significant factor in their selection.

Summary Table

| Material | Typical Use Case for primapore dressing | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Non-Woven Fabric | General wound management | Soft and low adherence | Less durable under high stress | Medium |

| Adhesive Layers | Secure dressing application | Strong initial tack | Potential for skin irritation | Medium |

| Absorbent Pads | Post-operative and chronic wounds | Reduces risk of maceration | Increases overall dressing cost | High |

| Water-Resistant Coatings | Hygiene maintenance in moist environments | Enhanced durability | May limit breathability | Medium |

This strategic material selection guide provides international B2B buyers with essential insights into the materials used in Primapore dressings. Understanding these aspects will aid in making informed decisions tailored to specific market needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for primapore dressing

The manufacturing process for Primapore dressings involves several critical stages that ensure the final product meets the high standards required in the medical industry. Understanding these processes is essential for B2B buyers, particularly those sourcing products from diverse global markets such as Africa, South America, the Middle East, and Europe.

Manufacturing Processes

1. Material Preparation

The foundation of Primapore dressings lies in the selection and preparation of materials. The primary components include non-woven fabrics and adhesive layers. Manufacturers typically source high-quality, hypoallergenic materials to minimize the risk of skin irritation. This stage involves:

- Raw Material Selection: Materials are chosen based on their absorbency, breathability, and hypoallergenic properties.

- Quality Inspection: Incoming materials undergo rigorous inspection to ensure compliance with industry standards. This includes checking for defects, contaminants, and consistency.

2. Forming

Once materials are prepared, the next step is forming the dressing components. This involves:

- Cutting and Shaping: The non-woven fabric is cut into specific sizes according to product specifications. Advanced cutting techniques, such as die-cutting, are often employed to ensure precision.

- Layering: The adhesive layer is applied to the non-woven fabric, forming the dressing’s main structure. This can involve techniques like lamination, ensuring that layers bond effectively without compromising material integrity.

3. Assembly

After forming, the components are assembled. This stage is crucial for ensuring the dressing’s functionality:

- Adhesive Application: The adhesive is uniformly applied to ensure optimal adhesion while maintaining breathability.

- Integration of Absorbent Pads: For dressings designed to manage exudate, absorbent pads are incorporated. This is typically done through automated systems that ensure consistent placement and secure adhesion.

4. Finishing

The finishing stage prepares the dressings for packaging and distribution. This includes:

- Quality Control Checks: Each batch undergoes quality control checks to identify any defects in adhesion or material integrity.

- Packaging: The finished dressings are packaged in sterile environments to maintain hygiene. Packaging is designed to be tamper-proof, ensuring product safety during transportation.

Quality Assurance

Quality assurance is paramount in the manufacturing of medical products like Primapore dressings. B2B buyers must be aware of the relevant international standards and specific industry requirements.

International Standards

- ISO 9001: This standard outlines the criteria for a quality management system and is applicable to any organization. Compliance indicates that a manufacturer has implemented effective processes to ensure product quality.

- CE Marking: In Europe, CE marking is mandatory for medical devices, indicating compliance with health, safety, and environmental protection standards.

- API Standards: For manufacturers producing components that interact with pharmaceuticals, adherence to API standards ensures that the materials are safe and effective for medical use.

Quality Control Checkpoints

Quality control is integrated throughout the manufacturing process. Key checkpoints include:

- Incoming Quality Control (IQC): This involves inspecting raw materials before they are used in production.

- In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process ensures that any deviations from quality standards are addressed immediately.

- Final Quality Control (FQC): At this stage, finished products are tested for performance and compliance with specifications before they are released for shipment.

Common Testing Methods

Manufacturers employ various testing methods to verify the integrity and performance of Primapore dressings, including:

- Adhesion Tests: To measure how well the dressing adheres to the skin under different conditions.

- Absorbency Tests: To ensure the dressing can manage exudate effectively.

- Breathability Tests: To assess how well the dressing allows air to circulate, which is crucial for wound healing.

Verifying Supplier Quality Control

For international B2B buyers, especially those from regions like Africa, South America, the Middle East, and Europe, verifying supplier quality control is critical. Here are actionable steps:

- Conduct Supplier Audits: Regular audits of manufacturing facilities can provide insights into operational practices and adherence to quality standards.

- Request Quality Reports: Ask suppliers for documentation detailing their quality control processes, including results from IQC, IPQC, and FQC.

- Third-Party Inspections: Engage third-party quality assurance firms to conduct independent inspections and testing of products before shipment.

Quality Control Nuances for International Buyers

B2B buyers must navigate various regulations and expectations when sourcing products across international borders. Here are some nuances to consider:

- Regulatory Compliance: Different countries have specific regulations regarding medical products. Buyers should ensure that their suppliers are compliant with local laws and international standards applicable in their target markets.

- Cultural Sensitivities: Understanding regional preferences and sensitivities regarding materials and product designs can enhance buyer-supplier relationships.

- Logistics and Supply Chain Management: Quality control does not end at the factory. Buyers should also consider the conditions under which products are transported and stored, as these factors can impact product integrity.

By understanding the manufacturing processes and quality assurance measures associated with Primapore dressings, B2B buyers can make informed decisions that ensure they source high-quality, reliable products for their markets.

Related Video: Complete Process of Textile Manufacturing Fiber to Complete Garments

Comprehensive Cost and Pricing Analysis for primapore dressing Sourcing

Understanding the cost structure and pricing dynamics of Primapore dressings is essential for international B2B buyers looking to make informed sourcing decisions. The following analysis covers the cost components, price influencers, and practical tips for buyers from regions such as Africa, South America, the Middle East, and Europe.

Cost Components

-

Materials: The primary material for Primapore dressings is a non-woven fabric, which is often combined with hypoallergenic adhesives for sensitive skin versions. The quality of these materials can significantly impact the overall cost, as higher-grade materials typically lead to better patient outcomes and reduced complications.

-

Labor: Labor costs are an important factor, particularly in regions with varying wage standards. Manufacturers in countries with lower labor costs may offer more competitive pricing, while those in developed regions might have higher labor costs, which could be reflected in the pricing of the dressings.

-

Manufacturing Overhead: This includes utilities, rent, and other operational expenses that contribute to the overall production costs. Efficient manufacturing processes and economies of scale can help mitigate these costs.

-

Tooling: The initial investment in machinery and tools necessary for producing Primapore dressings can be significant. Suppliers with advanced tooling capabilities can produce higher-quality products more efficiently, potentially lowering costs in the long run.

-

Quality Control (QC): Stringent QC processes ensure that products meet healthcare standards. The costs associated with QC can vary based on the certifications required, such as ISO or CE marks, which may be crucial for market entry in different regions.

-

Logistics: Shipping and handling costs are critical, especially for international buyers. Factors such as distance, freight method, and local customs duties can significantly influence the final price.

-

Margin: Suppliers typically add a margin to cover their costs and ensure profitability. This margin can vary based on market competition and perceived value of the product.

Price Influencers

-

Volume/MOQ: Minimum Order Quantities (MOQ) often play a crucial role in pricing. Bulk purchases can lead to significant discounts, so negotiating terms for larger orders can be beneficial.

-

Specifications/Customization: Custom specifications may increase costs, particularly if specialized materials or features are required. Buyers should weigh the benefits of customization against the potential price increase.

-

Materials: The choice of materials directly affects pricing. High-quality or specialized materials may command higher prices, but they could also enhance product performance and patient satisfaction.

-

Quality/Certifications: Certifications can impact both costs and buyer confidence. Products that meet rigorous quality standards may be priced higher but offer greater assurance of safety and efficacy.

-

Supplier Factors: The reputation and reliability of the supplier can also affect pricing. Established suppliers may charge more due to their proven track record and customer support.

-

Incoterms: Understanding Incoterms is crucial for international transactions. They define the responsibilities of buyers and sellers in shipping, which can affect overall costs and risk management.

Buyer Tips

-

Negotiation: Always seek to negotiate terms, especially for larger orders. Discussing payment terms, delivery timelines, and volume discounts can lead to more favorable pricing.

-

Cost-Efficiency: Consider the Total Cost of Ownership (TCO), which includes not only the purchase price but also shipping, handling, and potential wastage or returns. A lower initial cost may not always lead to overall savings.

-

Pricing Nuances: Be aware that pricing may vary significantly based on geographic location. Buyers in regions with less competition may face higher prices, while those in more competitive markets might find better deals.

-

Market Research: Conduct thorough market research to understand the going rates for Primapore dressings in your region. Utilize multiple suppliers to gauge pricing and service levels.

Disclaimer

Prices are indicative and can vary based on market conditions, supplier negotiations, and specific buyer needs. Always verify current prices and terms directly with suppliers before making purchasing decisions.

Spotlight on Potential primapore dressing Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘primapore dressing’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for primapore dressing

Understanding the technical properties and common trade terminology associated with Primapore dressings is essential for B2B buyers aiming to make informed purchasing decisions. This section outlines the critical specifications and industry terms that buyers should be familiar with to navigate the market effectively.

Key Technical Properties

-

Material Composition

– Primapore dressings are primarily made from a non-woven fabric that provides breathability and comfort. This material allows for moisture vapor transmission while protecting the wound from external contaminants. Understanding material composition is crucial for buyers to assess compatibility with patient needs and application scenarios. -

Adhesive Type

– The adhesive used in Primapore dressings is designed for secure adhesion while minimizing trauma upon removal. Different types of adhesives (e.g., hypoallergenic for sensitive skin) cater to varying patient sensitivities. Buyers should consider adhesive types to ensure they select a product that aligns with their patient demographics. -

Absorbency Level

– Primapore dressings have varying absorbency levels, which are critical for managing wound exudate. Knowing the absorbency characteristics helps buyers choose the right dressing based on the wound’s nature and expected drainage, thus improving healing outcomes and patient comfort. -

Water Resistance

– Certain Primapore dressings offer water-resistant features, allowing patients to engage in activities like bathing without compromising wound protection. This property is particularly significant for post-operative care, making it essential for buyers to evaluate the water resistance of products when considering their use in specific environments. -

Size Variability

– Primapore dressings are available in multiple sizes to accommodate different wound types and body areas. Buyers should understand the sizing options available to ensure they can provide adequate coverage for various patient needs, which is vital for effective wound management. -

Breathability

– The breathability of Primapore dressings is paramount for preventing maceration around the wound site. This property ensures that moisture does not accumulate, which could lead to infection. Buyers should prioritize breathable options to enhance patient comfort and healing.

Common Trade Terminology

-

OEM (Original Equipment Manufacturer)

– This term refers to companies that produce products that may be marketed by another company. In the context of Primapore dressings, buyers should identify OEMs to ensure they are sourcing high-quality products that meet industry standards. -

MOQ (Minimum Order Quantity)

– MOQ indicates the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for buyers to optimize inventory levels and avoid overstocking or stockouts, especially in markets with fluctuating demand. -

RFQ (Request for Quotation)

– An RFQ is a formal request sent to suppliers to obtain pricing and terms for products. Buyers should utilize RFQs to gather competitive quotes for Primapore dressings, ensuring they make cost-effective purchasing decisions. -

Incoterms (International Commercial Terms)

– These are a set of globally recognized rules defining the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms is crucial for buyers to understand shipping costs, risk management, and delivery responsibilities associated with Primapore dressing procurement. -

Lead Time

– Lead time refers to the amount of time it takes from placing an order to receiving the goods. Buyers should consider lead times when planning inventory and ensuring timely availability of Primapore dressings for patient care. -

Certification Standards

– Many medical products, including Primapore dressings, must meet specific certification standards (e.g., ISO, CE marking) to ensure safety and efficacy. Buyers should verify that products are certified to mitigate risks associated with non-compliance and ensure quality assurance.

By understanding these essential technical properties and trade terms, B2B buyers can make informed decisions that align with their business needs and enhance patient care outcomes.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the primapore dressing Sector

Market Overview & Key Trends

The global market for Primapore dressings is experiencing significant growth, driven by the increasing prevalence of chronic wounds, surgical procedures, and a rising geriatric population. Notably, regions like Africa, South America, the Middle East, and Europe are witnessing heightened demand due to their expanding healthcare infrastructure and increasing investment in medical supplies.

Emerging B2B technology trends such as telemedicine, digital supply chain management, and e-commerce platforms are reshaping the sourcing landscape. Buyers are leveraging online marketplaces to streamline procurement processes, gain competitive pricing, and enhance product accessibility. Additionally, data analytics is being utilized to forecast demand accurately, enabling suppliers to align their inventories with market needs effectively.

Market dynamics are also influenced by the growing emphasis on quality and safety standards in healthcare products. Regulatory compliance is becoming increasingly stringent, compelling manufacturers to innovate and improve product features, such as enhanced breathability and reduced adherence to wounds. B2B buyers should prioritize suppliers that demonstrate adherence to international quality standards, as this not only ensures product efficacy but also minimizes risk in procurement.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a crucial consideration in the procurement of Primapore dressings. The environmental impact of medical waste, including dressings, is significant, leading to a push for eco-friendly alternatives. B2B buyers are encouraged to seek suppliers that utilize biodegradable or recyclable materials in their dressings, which can significantly reduce the carbon footprint associated with healthcare waste.

Illustrative Image (Source: Google Search)

Moreover, the importance of ethical supply chains cannot be overstated. Buyers should ensure that their suppliers maintain transparency regarding sourcing practices, labor conditions, and environmental stewardship. Certifications such as ISO 14001 (Environmental Management) and FSC (Forest Stewardship Council) can serve as indicators of a supplier’s commitment to sustainability. By prioritizing suppliers with robust sustainability practices, B2B buyers can enhance their corporate social responsibility profiles while meeting the growing consumer demand for environmentally friendly products.

Brief Evolution/History

Primapore dressings have evolved significantly since their introduction in the medical field. Originally developed to provide basic wound coverage, advancements in material technology have led to the creation of specialized dressings that cater to various wound types and patient needs. The introduction of hypoallergenic adhesives and water-resistant options reflects an increasing understanding of patient comfort and care requirements. Today, Primapore dressings are recognized for their effectiveness in promoting healing while minimizing discomfort, making them a staple in both clinical and home care settings. This evolution underscores the importance of innovation in meeting the diverse needs of international B2B buyers in the healthcare sector.

Related Video: International Trade 101 | Economics Explained

Frequently Asked Questions (FAQs) for B2B Buyers of primapore dressing

-

What criteria should I consider when vetting suppliers for Primapore dressings?

When vetting suppliers, focus on their experience in the medical supply industry and their reputation within the market. Look for certifications such as ISO 13485 or CE marking, which indicate compliance with international quality standards. Assess their production capabilities, quality control processes, and customer service responsiveness. Additionally, check for references or testimonials from other B2B buyers, especially those from your region, to gauge reliability and service quality. -

Can Primapore dressings be customized for specific needs?

Yes, many suppliers offer customization options for Primapore dressings. This may include variations in size, adhesive type, or even packaging based on your requirements. To initiate customization, discuss your needs directly with suppliers and inquire about their design and manufacturing flexibility. Ensure that any customizations align with regulatory standards in your country to avoid compliance issues. -

What are typical minimum order quantities (MOQ) and lead times for Primapore dressings?

Minimum order quantities can vary significantly by supplier, but they often range from 500 to 1,000 units. Lead times for production and delivery typically range from 2 to 6 weeks, depending on the supplier’s inventory levels and production capacity. When negotiating, consider discussing flexibility on MOQs or expedited shipping options to meet urgent needs, especially if you are in a region with unpredictable supply chains. -

What payment terms are common when sourcing Primapore dressings internationally?

Payment terms can vary by supplier, but common practices include advance payments, letters of credit, or net 30-60 days upon delivery. It is essential to establish clear payment terms before finalizing orders to avoid disputes. Consider using secure payment methods and platforms that provide buyer protection, especially when dealing with new suppliers, to mitigate risks associated with international transactions. -

What quality assurance measures should I expect from suppliers of Primapore dressings?

Reputable suppliers should adhere to strict quality assurance protocols, including regular inspections and testing of their products. They should provide documentation demonstrating compliance with international standards, such as certificates of analysis or quality management system certifications. Request information on their quality control processes and whether they conduct third-party audits to ensure consistency and reliability in their products. -

How can I effectively manage logistics when importing Primapore dressings?

Managing logistics involves coordinating with freight forwarders who specialize in medical supplies to ensure compliance with import regulations. Be aware of customs requirements in your country, including necessary documentation and duties. Establish a clear communication line with your supplier regarding shipping methods, tracking options, and estimated delivery times. Consider potential delays due to customs clearance and plan your inventory levels accordingly. -

What should I do if a dispute arises with a supplier of Primapore dressings?

In the event of a dispute, begin by communicating directly with the supplier to resolve the issue amicably. Document all communications and agreements for reference. If direct negotiation fails, consult the terms of your contract regarding dispute resolution procedures. Depending on the situation, consider engaging a mediator or legal advisor familiar with international trade laws to assist in resolving the matter effectively. -

What certifications should I verify for suppliers of Primapore dressings?

When sourcing Primapore dressings, ensure that suppliers hold relevant certifications such as ISO 13485 for quality management systems specific to medical devices. Check for CE marking if you are operating within the European market, as this demonstrates compliance with EU safety standards. Additionally, inquire about any local certifications that may be required in your region, as these can impact the legality and marketability of the products.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for primapore dressing

In conclusion, the strategic sourcing of Primapore dressings presents a compelling opportunity for international B2B buyers across Africa, South America, the Middle East, and Europe. Understanding the diverse range of Primapore products—from standard to water-resistant and sensitive skin options—allows buyers to tailor their procurement strategies to meet specific healthcare needs effectively.

Key takeaways include:

– Versatility and Comfort: Primapore dressings are suitable for various applications, including post-operative care and everyday wound management, making them indispensable in healthcare settings.

– Quality Assurance: Sourcing from reputable manufacturers like Smith & Nephew ensures high-quality products that adhere to international standards, fostering trust and reliability in patient care.

As healthcare demands continue to evolve, strategic sourcing becomes vital for optimizing supply chains and ensuring timely availability of essential medical supplies. International buyers are encouraged to engage with trusted suppliers, evaluate the unique needs of their markets, and leverage the benefits of Primapore dressings to enhance patient outcomes. By doing so, they can position themselves as leaders in providing quality healthcare solutions in their regions.