Master the Art of Sourcing Level Dresses for Your Retail

Introduction: Navigating the Global Market for level dresses

In the dynamic world of fashion, level dresses represent a critical segment that combines versatility with style, catering to diverse markets across Africa, South America, the Middle East, and Europe. As international B2B buyers navigate the complexities of sourcing these essential garments, understanding the nuances of the level dress market becomes paramount. These dresses not only offer a canvas for creativity but also serve as staples in consumers’ wardrobes, making them vital for retailers looking to enhance their product offerings.

This guide is designed to empower B2B buyers with comprehensive insights into the level dress landscape. It covers various types of dresses, the materials that define quality and sustainability, and the manufacturing and quality control processes that ensure consistency. Additionally, we delve into the leading suppliers across global manufacturing hubs, discuss cost considerations, and analyze market trends that shape purchasing decisions.

By addressing frequently asked questions and providing actionable strategies, this guide equips buyers with the tools needed to make informed sourcing decisions. Whether you are a boutique owner in Paris or a retailer in Johannesburg, our insights will help you identify reliable partners and capitalize on emerging trends, ultimately driving profitability and customer satisfaction in your business.

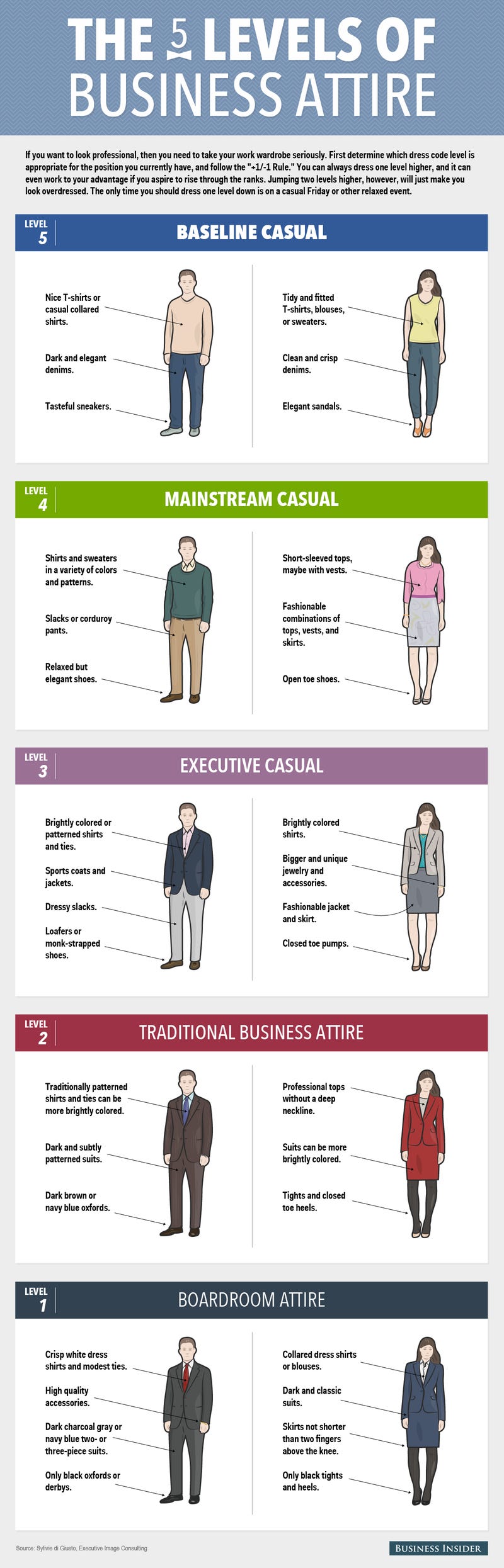

Understanding level dresses Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| A-Line Dresses | Fitted at the waist and flares gently towards the hem. | Retail boutiques, casual wear | Pros: Flattering for various body types; versatile. Cons: May require more fabric for larger sizes. |

| Shift Dresses | Loose-fitting, straight cut that hangs from the shoulders. | Office wear, casual outings | Pros: Comfortable and easy to wear; suitable for all body types. Cons: Less defined silhouette may not appeal to all customers. |

| Maxi Dresses | Long, flowing design that reaches the ankles or floor. | Summer collections, beachwear | Pros: Popular for casual and formal events; offers comfort and style. Cons: Limited wearability in cooler climates. |

| Bodycon Dresses | Form-fitting design that hugs the body, often made from stretchy fabric. | Nightclubs, parties, special events | Pros: Enhances body shape; trendy among younger demographics. Cons: May not cater to all body types; less comfortable for extended wear. |

| Wrap Dresses | Features a front closure by wrapping one side across the other. | Retail, maternity wear | Pros: Adjustable fit; flattering for various body shapes. Cons: Requires careful handling to maintain shape during washing. |

A-Line Dresses

A-line dresses are characterized by their fitted bodice and flared skirt, creating a silhouette that flatters various body types. They are ideal for retail boutiques focusing on casual wear, as they can easily transition from day to night. When sourcing A-line dresses, buyers should consider fabric quality and the dress’s versatility, as these factors significantly influence customer satisfaction and repeat purchases.

Shift Dresses

Shift dresses have a loose-fitting, straight cut that hangs from the shoulders, making them a comfortable choice for office wear or casual outings. These dresses are suitable for retailers targeting a wide demographic, as they can appeal to various customer preferences. Buyers should focus on the fabric’s breathability and ease of care, ensuring the dresses remain popular in diverse markets.

Maxi Dresses

Maxi dresses are known for their long, flowing design that reaches the ankles or floor, making them a popular choice for summer collections and beachwear. They cater to consumers looking for both comfort and style during warmer months. When purchasing maxi dresses, buyers should assess the fabric’s weight and drape to ensure it meets the expectations of their target market, especially in regions with varying climates.

Bodycon Dresses

Bodycon dresses are form-fitting garments made from stretchy fabric, designed to hug the body closely. These dresses are particularly popular in nightlife and special event settings, appealing to younger demographics. Buyers should consider the inclusivity of sizes when sourcing bodycon dresses, as this can significantly impact sales and brand reputation in a diverse marketplace.

Wrap Dresses

Wrap dresses feature a front closure achieved by wrapping one side across the other, offering an adjustable fit that flatters various body shapes. They are increasingly popular in maternity wear and among retailers looking to provide versatile options. Buyers should prioritize quality craftsmanship to ensure the dress maintains its shape after washing, which is crucial for customer satisfaction and brand loyalty.

Related Video: Lecture 1 Two compartment models

Key Industrial Applications of level dresses

| Industry/Sector | Specific Application of Level Dresses | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion Retail | Seasonal Collections for Boutiques | Enhances brand image and attracts diverse customer segments | Reliable manufacturers with fast turnaround and quality control |

| Event Planning | Custom Dresses for Events and Weddings | Provides unique offerings that meet specific client needs | Flexible production capabilities and customization options |

| Hospitality | Staff Uniforms and Guest Dresses | Improves guest experience and brand consistency | Durable fabrics and designs that align with brand identity |

| Film and Theatre | Costumes for Performances | Supports creative expression and enhances production quality | Expertise in fabric selection and quick production cycles |

| E-commerce | Online Exclusive Collections | Drives traffic and sales through limited-edition offerings | Strong logistics and shipping capabilities for international orders |

Fashion Retail

In the fashion retail sector, level dresses are essential for creating seasonal collections that resonate with current trends. Retailers can enhance their brand image by offering high-quality dresses that cater to diverse customer preferences. For international B2B buyers, particularly those from Europe and Africa, it is crucial to partner with reliable manufacturers that ensure fast turnaround times and rigorous quality control processes. This approach minimizes returns and fosters customer loyalty, ultimately driving sales.

Event Planning

Level dresses find significant application in event planning, particularly for custom dresses for weddings and corporate events. These dresses allow planners to provide unique offerings tailored to the specific needs of clients, enhancing customer satisfaction and loyalty. Buyers in regions like South America and the Middle East should prioritize manufacturers that offer flexible production capabilities and customization options to meet varying client demands and preferences, ensuring successful event outcomes.

Hospitality

In the hospitality industry, level dresses are utilized for staff uniforms and guest dresses, contributing to an improved guest experience and consistent brand representation. For international buyers, especially in Europe, it is vital to select manufacturers that provide durable fabrics and designs that reflect the establishment’s identity. This not only enhances the overall aesthetic but also reinforces brand consistency, which is critical in a competitive market.

Film and Theatre

The film and theatre industry leverages level dresses for costumes that support creative expression and enhance production quality. These dresses are designed to meet specific artistic requirements while ensuring comfort and durability for performers. Buyers in this sector should seek manufacturers with expertise in fabric selection and quick production cycles to accommodate tight production schedules, particularly for international projects that may involve diverse cultural aesthetics.

E-commerce

E-commerce platforms benefit from offering exclusive online collections of level dresses, driving traffic and increasing sales through limited-edition offerings. For B2B buyers, particularly in Africa and Europe, it is essential to partner with suppliers that have strong logistics and shipping capabilities for international orders. This ensures timely delivery and customer satisfaction, which are critical for maintaining a competitive edge in the fast-paced online retail environment.

Related Video: What are all the Laboratory Apparatus and their uses?

Strategic Material Selection Guide for level dresses

When selecting materials for level dresses, B2B buyers must consider various factors that impact product performance, cost, and suitability for their target markets. Here, we analyze four common materials used in the production of level dresses, focusing on their properties, advantages, disadvantages, and implications for international buyers.

Cotton

Key Properties: Cotton is a natural fiber known for its breathability, softness, and moisture-wicking abilities. It performs well in various temperatures, making it suitable for both warm and cool climates.

Pros & Cons: Cotton is durable and easy to dye, allowing for vibrant colors and patterns. However, it can wrinkle easily and may require more care in terms of washing and ironing. While generally affordable, high-quality cotton can be more expensive.

Impact on Application: Cotton is compatible with various media, including dyes and prints, making it a versatile choice for fashion. It is particularly favored in regions with warmer climates due to its comfort.

Considerations for International Buyers: Buyers should ensure that cotton sourcing complies with local regulations regarding pesticide use and labor practices. Certifications like OEKO-TEX can assure buyers of the material’s safety and sustainability.

Polyester

Key Properties: Polyester is a synthetic fabric known for its strength, durability, and resistance to shrinking and stretching. It has a low moisture absorption rate, making it quick-drying.

Pros & Cons: The fabric is cost-effective and can mimic the appearance of natural fibers, which allows for a wide range of applications. However, polyester is less breathable than cotton and can retain odors, which may be a drawback for some consumers.

Impact on Application: Polyester is often used in dresses that require a structured fit, as it holds its shape well. It is compatible with various finishes and treatments, enhancing its functionality.

Considerations for International Buyers: Buyers should be aware of the environmental impact of polyester production. Compliance with standards such as ASTM for fabric performance can help ensure product quality.

Linen

Key Properties: Linen is made from flax fibers and is known for its exceptional breathability and moisture-wicking properties. It has a natural luster and a crisp texture.

Pros & Cons: Linen is highly durable and becomes softer with each wash. However, it wrinkles easily, which may not appeal to all consumers. The cost of linen can be higher than cotton, particularly for high-quality varieties.

Impact on Application: Linen is ideal for summer dresses due to its lightweight nature and ability to keep the wearer cool. It works well with natural dyes, appealing to eco-conscious consumers.

Considerations for International Buyers: Buyers should consider sourcing linen from reputable suppliers who adhere to sustainable practices. Certifications like GOTS can enhance marketability in regions that prioritize eco-friendly products.

Silk

Key Properties: Silk is a luxurious fabric known for its smooth texture and natural sheen. It drapes beautifully and is lightweight, making it suitable for formal wear.

Pros & Cons: Silk offers a premium feel and is often associated with high-end fashion. However, it is more expensive than other fabrics and requires special care in washing and storage.

Impact on Application: Silk is often used in evening and formal dresses, where elegance is paramount. It is compatible with various embellishments, enhancing its appeal.

Considerations for International Buyers: Buyers should ensure that silk sourcing complies with ethical standards, particularly regarding labor practices in silk production. Knowledge of international trade regulations is also crucial when importing silk garments.

| Material | Typical Use Case for level dresses | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Cotton | Casual and summer dresses | Breathable and comfortable | Wrinkles easily | Medium |

| Polyester | Structured dresses | Durable and cost-effective | Less breathable | Low |

| Linen | Summer and eco-friendly dresses | Highly breathable and durable | Prone to wrinkling | High |

| Silk | Formal and evening dresses | Luxurious feel and elegant drape | Requires special care | High |

This strategic material selection guide provides B2B buyers with essential insights into the properties and implications of different fabrics used in level dresses, enabling informed sourcing decisions that align with market demands and compliance standards.

In-depth Look: Manufacturing Processes and Quality Assurance for level dresses

The manufacturing process for level dresses involves several critical stages that ensure the final product meets quality standards and consumer expectations. For B2B buyers, understanding these stages, along with the quality assurance measures in place, is essential for making informed sourcing decisions.

Manufacturing Processes for Level Dresses

1. Material Preparation

The first step in the manufacturing process involves selecting and preparing the materials. High-quality fabrics are crucial for creating level dresses, and buyers should prioritize suppliers that source premium materials.

- Fabric Selection: Common fabrics for level dresses include cotton, polyester, and blends. Each fabric type offers unique characteristics that influence the dress’s drape, durability, and comfort.

- Pre-treatment: Fabrics often undergo pre-treatment processes, such as washing or dyeing, to enhance their properties. This stage can include processes like mercerization for cotton, which improves strength and dye affinity.

2. Forming

Once the materials are prepared, the next stage is forming the garments. This includes cutting the fabric and creating the individual components of the dress.

- Cutting: Patterns are used to cut the fabric into specific shapes. Precision cutting is vital to reduce waste and ensure consistent sizing across production runs.

- Sewing Techniques: Various sewing techniques are employed, including straight stitching, zigzag stitching, and overlocking. Each technique serves a purpose, such as reinforcing seams or preventing fraying.

3. Assembly

After the components are formed, they are assembled into the final product. This stage involves several key steps:

- Joining: Different parts of the dress, such as sleeves, bodice, and skirt, are sewn together. Quality manufacturers often use double-stitched seams for added durability.

- Adding Details: Zippers, buttons, and embellishments are attached during this stage. Attention to detail here can significantly impact the overall aesthetic of the dress.

4. Finishing

The finishing stage is where the dress is made ready for market. This includes pressing, quality checks, and packing.

- Pressing: Dresses are pressed to ensure they have a crisp, professional appearance. This step can affect the first impression customers have of the garment.

- Quality Control Checkpoints: Each dress undergoes a final inspection to check for defects. This includes checking stitching, fabric integrity, and overall appearance.

Quality Assurance in Dress Manufacturing

Quality assurance is a critical aspect of the manufacturing process, ensuring that the final product meets international standards and industry expectations.

1. International Standards

B2B buyers should look for manufacturers that comply with recognized international quality standards. Key standards include:

- ISO 9001: This standard focuses on quality management systems and ensures that manufacturers maintain consistent quality in their processes.

- CE Marking: Required for products sold within the European Economic Area, CE marking indicates conformity with health, safety, and environmental protection standards.

2. Industry-Specific Certifications

In addition to general quality standards, some industries have specific requirements that manufacturers must adhere to. Examples include:

- API Certification: For manufacturers producing technical garments, such as those used in the oil and gas industry.

- OEKO-TEX Certification: This certification ensures that textiles are free from harmful substances, appealing to eco-conscious consumers.

3. Quality Control Checkpoints

Quality control (QC) involves several checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): This step involves inspecting raw materials upon arrival to ensure they meet specifications.

- In-Process Quality Control (IPQC): During production, manufacturers conduct regular checks to catch defects early.

- Final Quality Control (FQC): Before packing, the finished dresses are thoroughly inspected for any defects or inconsistencies.

4. Common Testing Methods

Manufacturers utilize various testing methods to ensure quality:

- Physical Testing: This includes testing fabric strength, colorfastness, and shrinkage.

- Chemical Testing: Ensures that fabrics do not contain harmful substances, complying with safety regulations.

Verifying Supplier Quality Control

B2B buyers must take proactive steps to verify the quality control processes of potential suppliers. Here are several strategies:

- Conduct Audits: Regular audits of manufacturing facilities can provide insights into the quality control processes and adherence to standards.

- Request Quality Reports: Suppliers should be able to provide documentation of their quality control measures and results from any relevant testing.

- Third-Party Inspections: Engaging third-party inspection services can offer an unbiased review of the manufacturing processes and quality standards.

Navigating QC and Certification Nuances for International Buyers

When sourcing from international suppliers, particularly in regions like Africa, South America, the Middle East, and Europe, buyers must be aware of specific nuances:

- Cultural Considerations: Understanding local manufacturing practices and quality perceptions can help in assessing supplier capabilities.

- Regulatory Compliance: Different regions may have varying regulations regarding textile production and safety standards. Buyers should be informed about these to ensure compliance.

- Communication: Clear communication with suppliers about quality expectations and certifications required can help prevent misunderstandings and ensure alignment.

Conclusion

For international B2B buyers, particularly those sourcing level dresses from diverse global markets, a comprehensive understanding of the manufacturing processes and quality assurance measures is essential. By focusing on high-quality materials, rigorous quality control, and effective supplier verification methods, buyers can enhance their sourcing strategies and build successful partnerships with manufacturers.

Related Video: Amazing Garment Manufacturing Process from Fabric to Finished Product Inside the Factory

Comprehensive Cost and Pricing Analysis for level dresses Sourcing

Understanding the cost structure and pricing dynamics of sourcing level dresses is crucial for international B2B buyers aiming to optimize their procurement strategies. The cost components involved in dress manufacturing can significantly influence overall pricing and profit margins.

Cost Components

-

Materials: The choice of fabrics significantly impacts costs. High-quality materials, such as organic cotton or silk, command higher prices but can yield better customer satisfaction and lower return rates. Conversely, synthetic fabrics like polyester may reduce upfront costs but could compromise perceived value.

-

Labor: Labor costs vary by region and can affect the pricing of level dresses. Countries with lower labor costs, such as Bangladesh or Vietnam, may offer competitive pricing. However, it’s essential to consider the skill level and working conditions, as these factors can influence the quality of the final product.

-

Manufacturing Overhead: This includes costs associated with factory operations, utilities, and administrative expenses. Efficient manufacturers with streamlined processes can offer lower overhead costs, which can be passed on to buyers.

-

Tooling: Initial tooling costs for unique designs or customizations can be significant. Buyers should be prepared for these upfront costs, especially if they require specific molds or patterns.

-

Quality Control (QC): Investing in robust QC processes is essential for maintaining product standards. While this may increase costs, it can lead to higher customer satisfaction and reduced returns.

-

Logistics: Shipping and handling costs can vary widely depending on the destination and Incoterms. Buyers should consider not just the shipping fees but also customs duties and taxes that may apply when importing dresses.

-

Margin: Manufacturers typically mark up prices to ensure profitability. Understanding the margin expectations of suppliers can help buyers negotiate better terms.

Price Influencers

Several factors influence the pricing of level dresses:

-

Volume/MOQ: Larger order quantities often lead to lower per-unit costs. Suppliers are more willing to offer discounts for bulk purchases.

-

Specifications/Customization: Custom designs or specifications can drive up costs. Standard designs usually have lower price points.

-

Materials: The choice of fabric and its quality play a critical role in pricing. Sustainable or high-end fabrics typically result in higher costs.

-

Quality/Certifications: Dresses that meet specific quality standards or certifications (e.g., GOTS for organic textiles) may have higher prices due to the costs associated with maintaining these standards.

-

Supplier Factors: The supplier’s reputation, location, and operational efficiencies can impact pricing. Established suppliers may charge a premium for their reliability.

-

Incoterms: Understanding Incoterms is vital as they define responsibilities regarding shipping, insurance, and tariffs. For example, choosing FOB (Free On Board) can allow buyers to control shipping costs more effectively.

Buyer Tips

To navigate the complexities of sourcing level dresses, consider the following actionable insights:

-

Negotiate Wisely: Don’t hesitate to negotiate prices, especially for larger orders. Suppliers often have room to maneuver on pricing.

-

Focus on Cost-Efficiency: Evaluate the Total Cost of Ownership (TCO) rather than just the upfront costs. Consider logistics, customs duties, and potential return rates when assessing total expenses.

-

Understand Pricing Nuances: Be aware that prices can fluctuate based on market conditions, seasonal demands, and fabric availability. Establish a good relationship with suppliers to stay informed about these changes.

-

Regional Considerations: For buyers in Africa, South America, the Middle East, and Europe, understanding local market conditions and consumer preferences can help tailor sourcing strategies effectively.

-

Disclaimer on Prices: Always approach pricing discussions with the understanding that costs can vary based on numerous factors, including exchange rates, seasonal demands, and supplier capacity. Ensure to request updated quotes regularly.

By comprehensively understanding these cost components and pricing influencers, B2B buyers can make informed decisions that enhance their sourcing strategies for level dresses.

Spotlight on Potential level dresses Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘level dresses’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for level dresses

In the competitive landscape of fashion retail, understanding the essential technical properties and trade terminology related to level dresses is crucial for B2B buyers. This knowledge not only facilitates better decision-making but also enhances communication with manufacturers and suppliers, ultimately leading to improved product quality and customer satisfaction.

Key Technical Properties of Level Dresses

-

Material Grade

Material grade refers to the quality and type of fabric used in the manufacturing of dresses. Common fabrics include cotton, polyester, silk, and blends. Each material grade affects the dress’s durability, comfort, and overall aesthetic. B2B buyers should prioritize high-grade materials to ensure product longevity and customer satisfaction. -

Tolerance

Tolerance denotes the allowable variation in dimensions or characteristics of the dresses during production. For instance, a tolerance of ±1 cm on the dress length ensures that minor discrepancies do not lead to significant quality issues. Understanding tolerances is vital for B2B buyers as it helps maintain consistency across production runs, reducing the risk of returns due to sizing issues. -

Weight and Drape

The weight of the fabric influences how a dress hangs and moves. Lighter fabrics, like chiffon, offer a flowing drape, while heavier fabrics, like wool, provide structure. Buyers should consider the intended use of the dress when evaluating weight and drape; for example, evening gowns may require more luxurious drapes, while casual dresses might benefit from lighter materials. -

Shrinkage Rate

The shrinkage rate indicates how much a fabric may shrink after washing. Fabrics with high shrinkage rates can lead to customer dissatisfaction if not disclosed properly. B2B buyers must inquire about the shrinkage rates of fabrics to avoid issues post-purchase, ensuring that customers receive products that meet their expectations.

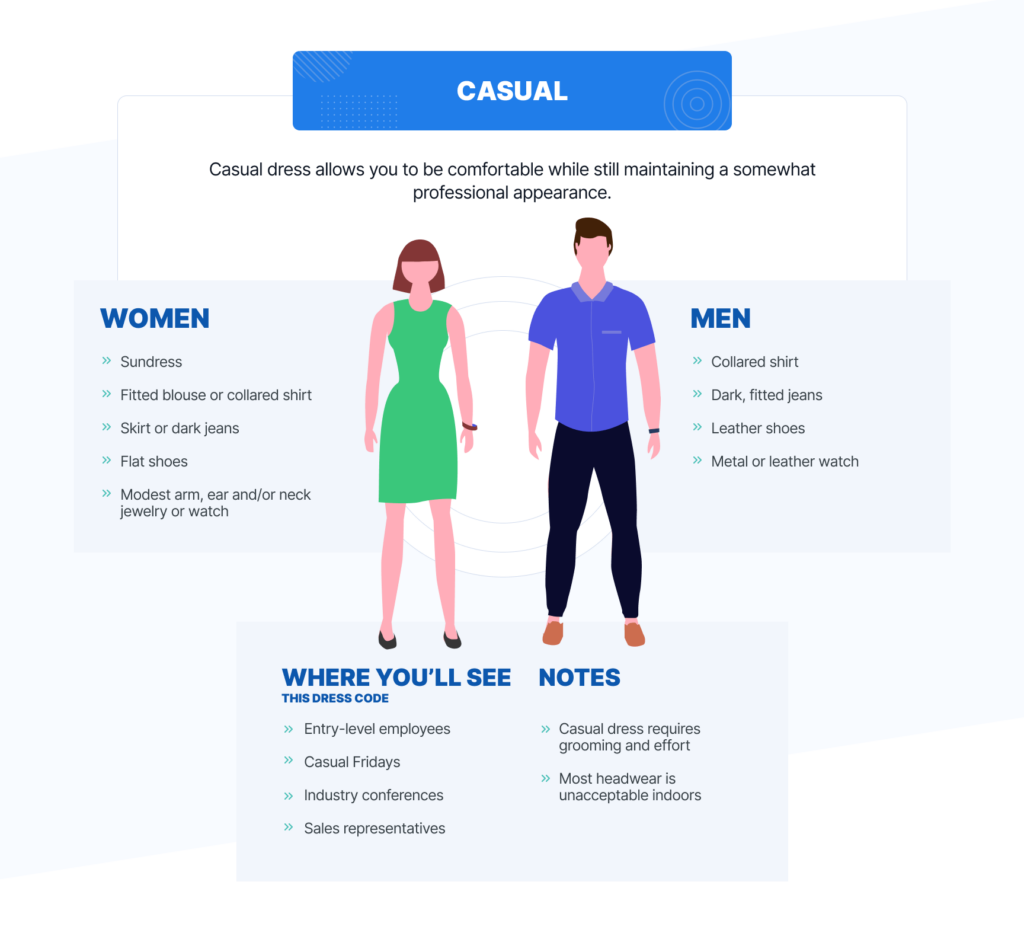

Illustrative Image (Source: Google Search)

- Colorfastness

Colorfastness measures a fabric’s ability to retain its color when exposed to washing, light, or rubbing. High colorfastness is crucial for maintaining the aesthetic appeal of dresses over time. Buyers should prioritize suppliers that provide information on colorfastness ratings to ensure the longevity of their products.

Common Trade Terminology

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or products that are used in another company’s end product. In the context of level dresses, an OEM might manufacture the dresses based on a retailer’s specifications. Understanding OEM relationships can help buyers leverage manufacturing capabilities effectively. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is vital for B2B buyers as it impacts inventory management and cash flow. Knowing the MOQ helps retailers plan their orders and avoid overstocking or stockouts. -

RFQ (Request for Quotation)

An RFQ is a document that buyers send to suppliers to request pricing information for a specific quantity of products. This process allows buyers to compare prices and terms from different manufacturers, aiding in informed decision-making. -

Incoterms (International Commercial Terms)

Incoterms are a series of predefined commercial terms published by the International Chamber of Commerce, outlining the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms, such as FOB (Free on Board) and CIF (Cost, Insurance, and Freight), is crucial for B2B buyers to understand shipping responsibilities and costs. -

Lead Time

Lead time is the time taken from placing an order to receiving the finished product. It is an essential factor for B2B buyers, as longer lead times can affect inventory levels and sales. Buyers should communicate their timelines clearly with manufacturers to ensure timely deliveries.

By grasping these technical properties and trade terms, B2B buyers can enhance their sourcing strategies, streamline communications with manufacturers, and ultimately improve their product offerings in the competitive fashion market.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the level dresses Sector

Market Overview & Key Trends

The global level dresses market is experiencing significant shifts driven by evolving consumer preferences, technological advancements, and sustainability imperatives. As international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, understanding these dynamics is crucial for making informed sourcing decisions.

One of the primary drivers of market growth is the increasing demand for versatile and fashionable dresses that cater to diverse cultural and climatic needs. Retailers are shifting towards suppliers who can provide quick turnaround times and adaptability in production to keep pace with fast-changing trends. Emerging technologies, such as AI-driven design and predictive analytics, are helping manufacturers optimize inventory management and reduce lead times, which is particularly beneficial for buyers looking to minimize stock risks.

Moreover, the rise of e-commerce has intensified competition, prompting brands to differentiate their offerings through unique designs and customization options. B2B buyers should focus on manufacturers that can provide flexible production capabilities and a diverse range of materials. This flexibility is essential in catering to local markets where fashion preferences can vary widely.

Another notable trend is the integration of circular economy principles in sourcing practices. Companies are increasingly adopting strategies that focus on recycling materials and minimizing waste, aligning with consumer expectations for sustainable practices.

Sustainability & Ethical Sourcing in B2B

Sustainability has become a cornerstone of the level dresses sector, with an increasing number of consumers prioritizing ethical sourcing and environmental impact in their purchasing decisions. For B2B buyers, this shift underscores the importance of selecting manufacturers committed to sustainable practices.

The environmental impact of clothing production is significant, contributing to pollution, water usage, and waste. Ethical supply chains help mitigate these effects by using sustainable materials and responsible production methods. Buyers should prioritize manufacturers that utilize eco-friendly fabrics such as organic cotton, Tencel, and recycled polyester. These materials not only reduce environmental harm but also appeal to the growing segment of eco-conscious consumers.

Certifications play a crucial role in validating a manufacturer’s commitment to sustainability. Look for certifications like GOTS (Global Organic Textile Standard), OEKO-TEX, and Fair Trade, which indicate adherence to strict environmental and social criteria. Establishing partnerships with certified manufacturers not only enhances brand credibility but also positions businesses to meet regulatory requirements and consumer expectations regarding sustainability.

Brief Evolution/History

The level dresses sector has evolved considerably over the decades, transitioning from traditional craftsmanship to a more industrialized approach. In the early 20th century, dresses were primarily handmade, with a focus on bespoke designs. However, the mid-century saw the rise of ready-to-wear clothing, driven by technological advancements in textile production and manufacturing processes.

The introduction of synthetic fabrics in the 1960s further revolutionized the industry, allowing for more innovative designs and greater accessibility. Today, the market is characterized by a mix of fast fashion and sustainable practices, as brands strive to balance profitability with ethical responsibilities. This evolution reflects broader societal changes, where consumer demand for transparency and sustainability continues to shape the future of fashion. For B2B buyers, understanding this history provides valuable context for navigating current market dynamics and sourcing strategies.

Related Video: Specialization and Trade: Crash Course Economics #2

Frequently Asked Questions (FAQs) for B2B Buyers of level dresses

-

What should I consider when vetting suppliers for level dresses?

When vetting suppliers, prioritize their experience in manufacturing level dresses and their ability to meet your quality standards. Request samples to evaluate fabric quality and craftsmanship. Investigate the supplier’s reputation through reviews and references from other B2B buyers. Ensure they have established quality control processes and certifications relevant to your target market, such as OEKO-TEX or GOTS. Additionally, assess their production capacity and flexibility to adapt to changing demands. -

Can I customize level dresses to fit my brand’s style?

Yes, many B2B manufacturers offer customization options for level dresses. This includes variations in design, fabric choices, and sizes. When discussing customization, clearly communicate your specific requirements, including color palettes and style preferences. Be aware that customization may affect minimum order quantities (MOQs) and lead times. Establish a detailed agreement to ensure that the final product aligns with your brand’s identity and market expectations. -

What are the typical minimum order quantities (MOQs) and lead times for level dresses?

MOQs for level dresses can vary significantly based on the manufacturer and the complexity of the designs. Generally, MOQs may range from 100 to 500 units per style. Lead times typically span from 4 to 12 weeks, depending on the supplier’s production schedule and your order size. To optimize your supply chain, consider placing larger orders to reduce per-unit costs while ensuring you have sufficient stock to meet market demand.

Illustrative Image (Source: Google Search)

-

What payment terms are common in international B2B transactions?

Payment terms can vary widely, but common practices include a 30% deposit upfront and the remaining 70% upon delivery or before shipment. Some suppliers may offer letter of credit (LC) options for added security. It’s crucial to negotiate terms that protect your interests while maintaining a good relationship with the supplier. Always document payment agreements clearly to avoid disputes later on. -

How can I ensure quality assurance and certifications for level dresses?

To ensure quality assurance, ask suppliers for their quality control processes and any relevant certifications. Look for manufacturers that adhere to international standards, such as ISO certifications or specific garment industry standards. Requesting third-party inspections before shipment can also help verify product quality. Establishing a clear quality agreement in your contract will help mitigate risks associated with defective products. -

What logistics considerations should I keep in mind when sourcing level dresses?

Logistics is a crucial factor in international B2B sourcing. Consider shipping methods, costs, and delivery times when finalizing orders. Work with suppliers who have experience in managing international shipments to navigate customs regulations efficiently. Additionally, factor in warehousing solutions to manage inventory effectively once the dresses arrive. Establishing a reliable logistics partner can streamline the entire process and reduce potential delays. -

How can I resolve disputes with suppliers effectively?

Dispute resolution should be addressed in your contract with suppliers. Clearly outline procedures for handling disagreements, including timelines for resolution and methods (e.g., mediation or arbitration). Maintain open lines of communication to address issues promptly before they escalate. Document all correspondence and agreements, as this can provide evidence in case of disputes. Building a strong relationship with suppliers can also help in resolving issues amicably. -

What trends should I be aware of when sourcing level dresses?

Stay informed about emerging trends such as sustainable fabrics, eco-friendly production practices, and the demand for customization. Consumers are increasingly valuing ethical sourcing and sustainable materials, which can influence your purchasing decisions. Additionally, monitor fashion trends in your target markets to ensure your offerings remain relevant. Engaging with trend forecasting services or industry reports can provide valuable insights to keep your product line competitive.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for level dresses

The journey of strategic sourcing in the level dresses market reveals critical insights for international B2B buyers. Prioritizing quality over cost is essential; partnering with manufacturers that uphold stringent quality controls can significantly enhance brand loyalty and reduce returns. Sustainability is no longer optional; buyers should seek suppliers that offer eco-friendly fabrics and ethical production methods, aligning with the values of a growing segment of consumers.

Additionally, the ability to adapt to current trends—from fast fashion to customization—can give retailers a competitive edge. By diversifying your sourcing strategy to include both rapid-turnaround suppliers and those focused on sustainable practices, you can cater to a broader customer base.

As the fashion landscape continues to evolve, international B2B buyers from Africa, South America, the Middle East, and Europe must remain vigilant and proactive. Embrace innovation and keep an eye on market trends to ensure your offerings resonate with consumers. Take the next step: evaluate your current suppliers, explore new partnerships, and commit to a sourcing strategy that meets both quality and ethical standards. The future of your business depends on the choices you make today.