Master Sourcing 1920s Flapper Dresses for Global B2B

Guide to 1920S Flapper Dresses

- Introduction: Navigating the Global Market for 1920s flapper dresses

- Understanding 1920s flapper dresses Types and Variations

- Key Industrial Applications of 1920s flapper dresses

- Strategic Material Selection Guide for 1920s flapper dresses

- In-depth Look: Manufacturing Processes and Quality Assurance for 1920s flapper dresses

- Comprehensive Cost and Pricing Analysis for 1920s flapper dresses Sourcing

- Spotlight on Potential 1920s flapper dresses Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for 1920s flapper dresses

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the 1920s flapper dresses Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of 1920s flapper dresses

- Strategic Sourcing Conclusion and Outlook for 1920s flapper dresses

Introduction: Navigating the Global Market for 1920s flapper dresses

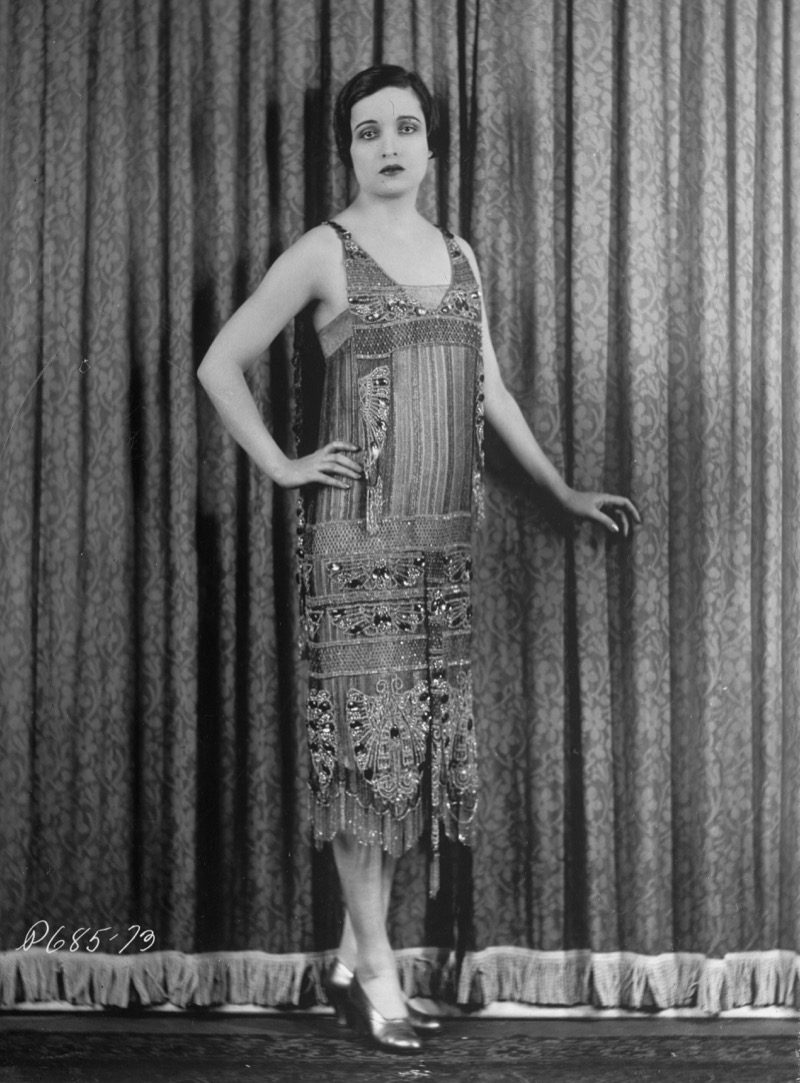

The allure of 1920s flapper dresses transcends mere fashion nostalgia, representing a dynamic intersection of cultural heritage, craftsmanship, and contemporary market demand. For international B2B buyers—especially those operating in diverse regions such as Africa, South America, the Middle East, and Europe—understanding this iconic garment’s historical significance and modern adaptations is essential to making strategic sourcing decisions that resonate with their target markets.

Flapper dresses epitomize the Jazz Age’s spirit of liberation, characterized by their distinctive silhouettes, materials, and embellishments. Their appeal today spans vintage enthusiasts, theatrical productions, and fashion-forward retail segments seeking authentic or inspired designs. However, navigating the global supply landscape requires more than appreciation; it demands comprehensive knowledge of dress types, fabric selections, manufacturing standards, quality control protocols, and cost structures.

This guide offers a thorough exploration tailored to empower international buyers by providing:

- Detailed breakdowns of flapper dress styles and variations to meet diverse consumer preferences

- Insights into sourcing quality materials and trims that reflect authentic 1920s aesthetics

- Evaluation criteria for manufacturers and suppliers, emphasizing reliability and compliance

- Cost analysis frameworks to optimize investment while maintaining product integrity

- Market trends and demand forecasts relevant to regions like Poland, South Africa, Brazil, and the Gulf states

- Frequently asked questions and troubleshooting tips to anticipate challenges in procurement and distribution

By leveraging this knowledge, buyers will be equipped to identify trustworthy partners, streamline supply chains, and capitalize on the enduring popularity of 1920s flapper dresses—turning cultural icons into profitable business opportunities across global markets.

Understanding 1920s flapper dresses Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Classic Shift Dress | Straight, loose silhouette; dropped waist; knee-length hemlines | Retail boutiques, costume suppliers | Pros: Simple production, versatile market appeal; Cons: May lack premium appeal for luxury segments |

| Beaded Evening Flapper | Heavily embellished with beads and sequins; shorter hemlines | High-end fashion retailers, event wear suppliers | Pros: High perceived value, premium pricing potential; Cons: Higher production cost, delicate handling |

| Daytime Flapper Dress | Plain fabrics, modest embellishments, calf-length hemlines | Mass-market apparel, casual wear distributors | Pros: Cost-effective, broad appeal; Cons: Lower profit margins, less distinctive |

| Art Deco Inspired Dress | Geometric patterns, metallic accents, asymmetric hems | Designer labels, niche fashion markets | Pros: Trend-driven, unique; Cons: Limited mass-market appeal, requires skilled craftsmanship |

| Fringed Flapper Dress | Layers of fringes creating movement; knee-length | Dancewear suppliers, theatrical costume vendors | Pros: Popular for performance wear, dynamic visual appeal; Cons: Niche market, seasonal demand |

Classic Shift Dress

The Classic Shift Dress embodies the quintessential flapper silhouette with its straight, loose fit and dropped waist, typically finishing at the knee. This style is highly suitable for mass production due to its simple construction, making it attractive for retailers targeting broad demographics across Africa, South America, and Europe. B2B buyers should consider fabric sourcing and the ease of customization to meet regional preferences. Its versatility supports both casual and semi-formal markets, although it may not meet luxury segment expectations without added embellishments.

Beaded Evening Flapper

This variation is distinguished by intricate beadwork and sequins, often paired with shorter hemlines that expose the knees, epitomizing 1920s glamour. Ideal for high-end fashion retailers and event wear suppliers, these dresses command premium pricing but require skilled artisans and careful quality control. B2B buyers should evaluate suppliers’ craftsmanship capabilities and logistics for delicate goods. This type appeals strongly to affluent markets in Europe and the Middle East, where demand for luxury vintage-inspired garments is growing.

Daytime Flapper Dress

Daytime flapper dresses use plain fabrics with minimal embellishments and typically feature calf-length hemlines, catering to more conservative markets or casual wear segments. Their cost-effective production suits mass-market apparel distributors, especially in emerging markets like South Africa and parts of Latin America. Buyers should focus on sourcing durable materials and efficient manufacturing to maximize margins. While offering broad appeal, these dresses may require marketing efforts to elevate their fashion status.

Art Deco Inspired Dress

Characterized by geometric patterns, metallic accents, and asymmetric hems, Art Deco inspired flapper dresses attract niche fashion consumers seeking unique statement pieces. These dresses are well-suited for designer labels and boutique sellers targeting European and Middle Eastern markets with an appetite for retro luxury fused with modern aesthetics. B2B buyers must prioritize suppliers with expertise in complex embellishments and quality metallic fabric sourcing. This category demands higher investment but can yield strong brand differentiation.

Fringed Flapper Dress

Fringed flapper dresses feature layered fringes that enhance movement, making them popular for dancewear and theatrical costumes. Their dynamic visual appeal opens opportunities with performance wear suppliers and costume rental businesses globally. Buyers targeting African and South American markets can leverage local dance traditions to boost sales. However, fringe construction requires specialized manufacturing and often leads to seasonal demand fluctuations. Effective inventory management and marketing are crucial for maximizing returns.

Related Video: 1920s Vintage Flapper Style Dresses by Nataya

Key Industrial Applications of 1920s flapper dresses

| Industry/Sector | Specific Application of 1920s Flapper Dresses | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion & Apparel | Vintage-inspired clothing lines and costume manufacturing | Captures consumer demand for retro and period styles | Authentic fabric sourcing, accurate design reproduction, ethical labor |

| Entertainment & Media | Film, theater, and television costume design | Enhances historical accuracy and visual appeal | Quality of materials, durability for repeated use, cultural relevance |

| Event Management | Themed parties and corporate events attire | Creates immersive, memorable experiences | Bulk availability, size range diversity, ease of customization |

| Tourism & Hospitality | Heritage hotels and cultural tours uniform design | Strengthens brand identity through period-appropriate attire | Comfort, fabric breathability, supplier reliability |

| Retail & E-commerce | Specialty vintage fashion retail and online marketplaces | Differentiates product offerings and attracts niche markets | Inventory scalability, fast replenishment, competitive pricing |

Fashion & Apparel:

For fashion brands and manufacturers targeting vintage or retro-inspired collections, 1920s flapper dresses offer a distinctive style that resonates globally. These dresses solve the challenge of blending historical aesthetics with modern wearability. International B2B buyers, especially in regions like Europe and South Africa, should prioritize authentic fabric sourcing (silk, chiffon, beads) and ensure designs respect the original silhouette and embellishments. Ethical production and scalable manufacturing are critical to meet growing consumer demand for sustainable vintage fashion.

Entertainment & Media:

Film studios, theater companies, and TV productions rely on 1920s flapper dresses to achieve period accuracy and enhance storytelling. These garments must withstand extensive use while maintaining visual fidelity. Buyers from the Middle East and South America should focus on durability, fabric quality, and supplier expertise in period costume replication. Collaborations with specialized costume houses can ensure garments meet rigorous artistic and functional standards, supporting seamless production workflows.

Event Management:

Corporate events, themed parties, and cultural celebrations frequently incorporate 1920s flapper dresses to create immersive atmospheres. This application addresses the need for authentic yet comfortable attire that can be rented or purchased in bulk. Buyers in Africa and Europe should consider suppliers offering a wide size range and customization options to accommodate diverse clientele. Reliable logistics and timely delivery are essential for event planners coordinating large-scale functions.

Tourism & Hospitality:

Heritage hotels, cultural centers, and guided tours use 1920s flapper dresses as staff uniforms to reinforce brand storytelling and elevate guest experiences. These dresses need to balance historical accuracy with comfort and practicality for prolonged wear. International buyers, particularly from South Africa and Poland, must source breathable fabrics and ensure supplier reliability to maintain consistent uniform standards that align with their cultural branding strategies.

Retail & E-commerce:

Specialty retailers and online marketplaces catering to vintage fashion enthusiasts benefit from stocking 1920s flapper dresses to attract niche customers. This application solves the challenge of differentiating product lines in a competitive market. Buyers should focus on inventory scalability, fast replenishment cycles, and competitive pricing to maximize sales across diverse regions, including South America and Europe. Partnering with manufacturers who offer flexible order quantities and trend-responsive designs is advantageous.

Related Video: LABORATORY APPARATUS AND THEIR USES

Strategic Material Selection Guide for 1920s flapper dresses

When sourcing materials for 1920s flapper dresses, international B2B buyers must carefully evaluate fabric characteristics to meet both historical authenticity and modern production demands. The choice of material impacts not only the garment’s look and feel but also manufacturing complexity, cost, and suitability for different climates and markets, especially across diverse regions such as Africa, South America, the Middle East, and Europe.

Silk

Key Properties: Silk is a natural protein fiber known for its smooth texture, excellent drape, and natural sheen. It is breathable and lightweight, making it suitable for warm climates. However, silk is sensitive to moisture and can degrade with prolonged exposure to sunlight or harsh chemicals.

Pros & Cons: Silk offers luxurious appearance and comfort, ideal for evening flapper dresses that require fluid movement and shine. It is durable when cared for properly but expensive and requires delicate handling during manufacturing. Silk’s susceptibility to staining and its need for dry cleaning can increase end-user maintenance costs.

Impact on Application: Silk’s breathability suits warmer climates in Africa and the Middle East, but its delicate nature may pose challenges in humid or highly variable environments. It is favored in European markets (e.g., Poland) for premium fashion lines, where consumers appreciate historical accuracy and luxury.

International Considerations: Compliance with international textile standards such as OEKO-TEX and REACH is critical for silk imports. Buyers should verify certifications to ensure chemical safety and sustainable sourcing, particularly for markets with strict regulations like the EU. Cost and supply chain reliability vary by region, with South America offering competitive silk production but sometimes facing logistical challenges.

Rayon (Viscose)

Key Properties: Rayon is a semi-synthetic fiber made from regenerated cellulose. It mimics silk’s softness and drape but is more affordable and easier to dye. Rayon is breathable but less durable when wet and prone to shrinking if not treated properly.

Pros & Cons: Rayon provides a cost-effective alternative to silk with good aesthetic qualities for flapper dresses. It is easier to manufacture and widely available globally. However, it can wrinkle easily and may degrade faster than silk or synthetic fibers, impacting garment longevity.

Impact on Application: Rayon’s versatility makes it popular in South American and African markets where budget constraints exist but style is important. It suits indoor or moderate climates but may require blending with other fibers for enhanced durability in humid or hot regions like the Middle East.

International Considerations: Buyers should ensure rayon fabric meets ASTM or ISO textile standards for strength and colorfastness. Environmental concerns about rayon production (e.g., chemical use) are increasingly relevant in Europe and South Africa, prompting demand for eco-certified variants.

Chiffon

Key Properties: Chiffon is a lightweight, sheer fabric traditionally made from silk but also available in synthetic fibers like polyester. It offers excellent drape and a delicate, flowing appearance but is prone to snagging and requires careful handling.

Pros & Cons: Chiffon is ideal for overlay skirts and decorative elements on flapper dresses, enhancing the period’s characteristic layered look. It is relatively affordable when synthetic but less breathable than natural fibers. The manufacturing process can be complex due to the fabric’s delicate nature.

Impact on Application: Chiffon’s lightness is advantageous in hot climates such as the Middle East and parts of Africa, providing airy comfort. European buyers often prefer silk chiffon for authenticity, while synthetic chiffon appeals more to cost-sensitive markets in South America.

International Considerations: Compliance with fire safety standards is important in many regions, especially for evening wear. Synthetic chiffon may meet these more easily. Buyers should also consider local preferences for fabric care, as chiffon typically requires gentle washing or dry cleaning.

Beaded Fabrics (Embellished Mesh or Net)

Key Properties: Beaded fabrics combine a base mesh or net fabric with sewn-on glass, plastic, or metal beads. These materials add texture, weight, and sparkle but increase garment fragility and production complexity.

Pros & Cons: Beaded fabrics are quintessential for authentic 1920s flapper dresses, especially for evening wear. They provide visual impact and luxury appeal but are costly and labor-intensive to produce. The added weight can affect comfort and drape.

Impact on Application: These fabrics are best suited for markets with a strong demand for premium, event-specific garments, such as European fashion hubs and affluent Middle Eastern buyers. In regions like Africa and South America, demand may be more niche due to cost and maintenance considerations.

International Considerations: Import regulations on beads (especially glass or metal) vary by country, with some requiring specific certifications or restrictions. Buyers must ensure compliance with customs and safety standards, and factor in longer lead times due to handcrafting requirements.

| Material | Typical Use Case for 1920s flapper dresses | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Silk | Evening and luxury flapper dresses with smooth drape | Luxurious sheen and breathability | High cost, delicate care, sensitive to moisture | High |

| Rayon (Viscose) | Affordable day and evening flapper dresses | Cost-effective silk alternative with good drape | Less durable when wet, prone to wrinkles | Medium |

| Chiffon | Sheer overlays and decorative layers | Lightweight, flowing appearance | Delicate, prone to snagging, requires careful handling | Medium |

| Beaded Fabrics | Embellished evening flapper dresses | High visual impact and authentic sparkle | Labor-intensive, heavy, costly | High |

In-depth Look: Manufacturing Processes and Quality Assurance for 1920s flapper dresses

The manufacturing of 1920s flapper dresses involves a blend of traditional garment construction techniques and specialized finishing to capture the iconic style of the Jazz Age. For international B2B buyers, particularly those operating in Africa, South America, the Middle East, and Europe, understanding the detailed manufacturing stages and quality assurance practices is crucial to ensuring product authenticity, durability, and compliance with global standards.

Manufacturing Process of 1920s Flapper Dresses

1. Material Preparation

Flapper dresses typically use lightweight fabrics such as silk, chiffon, crepe, and rayon to achieve the fluid drape and movement characteristic of the era. Material preparation includes:

– Fabric inspection and sourcing: Ensuring fabric meets colorfastness, texture, and weight specifications. Authentic vintage-style fabric sourcing or modern equivalents are selected based on buyer requirements.

– Pre-treatment: Washing or steaming fabrics to remove impurities and stabilize shrinkage before cutting. This step is essential for maintaining garment shape and longevity.

– Pattern development: Using historically accurate patterns, often adapted to modern sizing. Many manufacturers leverage CAD systems to digitize and modify 1920s patterns for precision.

2. Cutting and Forming

– Fabric cutting: Precision cutting is done either manually or with automated cutting machines to ensure clean edges and consistency across production batches.

– Shaping and darts: The flapper dress silhouette is straight and loose with minimal shaping, but careful attention is paid to details such as dropped waistlines and scalloped or handkerchief hemlines, which require precise cutting.

– Seam allowance and reinforcement: Since flapper dresses are designed for movement (e.g., dancing the Charleston), seams are reinforced to prevent tearing.

3. Assembly

– Sewing: Assembly typically involves straight stitching for the shift-style dress, with additional techniques such as French seams or flat-felled seams to enhance durability and reduce bulk.

– Decorative elements: Embellishments like beading, sequins, and fringe are hand-applied or machine-stitched. This step requires skilled artisans or specialized machinery, particularly for intricate patterns that evoke 1920s glamour.

– Attachment of linings and underlayers: Many flapper dresses have sheer overlays with solid linings; assembly ensures layers align perfectly to maintain aesthetic and comfort.

4. Finishing

– Hemming: Hemlines are finished with scalloped or handkerchief styles, often requiring hand-finishing to maintain authenticity.

– Pressing and steaming: Final pressing ensures the garment maintains its shape and fluidity.

– Quality tagging and packaging: Labels indicating fabric content, care instructions, and compliance marks are affixed. Packaging is designed to prevent damage during transit, a critical consideration for international shipments.

Quality Assurance (QA) and Quality Control (QC) Frameworks

Relevant International and Industry Standards

– ISO 9001: The globally recognized standard for quality management systems (QMS). Suppliers adhering to ISO 9001 demonstrate consistent manufacturing processes, continuous improvement, and customer satisfaction focus.

– OEKO-TEX Standard 100: Particularly relevant for textiles, ensuring fabrics are free from harmful substances—a critical consideration for buyers in markets with strict import regulations.

– Compliance with regional standards: For example, CE marking is less common in apparel but important if garments include electronic components or special materials; buyers in the Middle East and Europe should verify any local regulatory requirements.

Key Quality Control Checkpoints

– Incoming Quality Control (IQC): Inspection of raw materials and components such as fabric, trims, and embellishments. IQC ensures materials meet buyer specifications before production begins.

– In-Process Quality Control (IPQC): Continuous monitoring during cutting, sewing, and assembly stages. IPQC includes checking seam integrity, stitch density, and adherence to design patterns to minimize defects early.

– Final Quality Control (FQC): Comprehensive inspection of finished garments covering measurements, color consistency, embellishment quality, and overall appearance. FQC also includes functional testing like stretch and durability assessments.

Common Testing Methods

– Dimensional inspection: Verifying garment measurements against agreed specifications using templates or digital measuring tools.

– Colorfastness tests: Assessing resistance to washing, rubbing, and light exposure, critical for maintaining appearance during use.

– Tensile strength and seam strength tests: Ensuring durability under stress, especially important for dresses designed for active use.

– Embellishment adhesion tests: Verifying beads, sequins, and fringe attachments withstand handling and wear.

How B2B Buyers Can Verify Supplier Quality Control

- Factory Audits: Conduct or commission on-site audits focusing on QMS implementation, worker skills, machinery condition, and compliance with standards. Audits help verify claims of ISO 9001 certification and adherence to buyer specifications.

- Reviewing QC Reports: Request detailed inspection reports covering IQC, IPQC, and FQC stages. These reports should include photographic evidence and data on defect rates and corrective actions.

- Third-Party Inspection Services: Employ independent inspection agencies (e.g., SGS, Bureau Veritas) to perform pre-shipment inspections and lab testing. This adds an objective layer of quality assurance and reduces risk of non-compliance.

- Sample Testing: Order pre-production and production samples to evaluate workmanship, fabric quality, and finish before full-scale orders.

QC and Certification Nuances for International Buyers by Region

- Africa and South America:

Buyers should emphasize certifications like OEKO-TEX and ISO 9001 due to increasing regulatory scrutiny on imported textiles. Import duties and customs can delay shipments if documentation or quality certificates are incomplete. Partnering with suppliers who provide transparent QC data and certification helps expedite customs clearance. - Middle East:

Compliance with local standards (e.g., GSO standards for Gulf countries) is critical. Some markets require halal certification for textile processing chemicals, which can impact supplier selection. Buyers should verify that suppliers understand these regional nuances and provide relevant certifications. - Europe (e.g., Poland):

European buyers often demand strict adherence to sustainability and safety standards, including REACH regulations for chemicals used in textiles. ISO 9001 certification is typically a minimum requirement, supplemented by audits focusing on environmental compliance and worker safety. Traceability in the supply chain is increasingly important.

Strategic Takeaways for B2B Buyers

- Prioritize Suppliers with Proven QMS: Selecting manufacturers certified under ISO 9001 and OEKO-TEX reduces risk and ensures consistent product quality.

- Leverage Technology: Encourage suppliers to use CAD pattern-making and automated cutting to enhance precision and reduce fabric waste.

- Insist on Multi-Stage QC Documentation: Comprehensive IQC, IPQC, and FQC reports enable early detection of issues and maintain product integrity throughout production.

- Invest in Third-Party Inspections: Independent verification is especially valuable for new supplier relationships or large-volume orders to safeguard against quality lapses.

- Understand Regional Compliance: Tailor supplier requirements and QC expectations to the specific import regulations and cultural preferences of your target markets.

By thoroughly understanding the manufacturing nuances and embedding rigorous quality assurance practices, international B2B buyers can confidently source authentic and high-quality 1920s flapper dresses that meet both aesthetic demands and regulatory requirements across diverse global markets.

Related Video: Complete Process of Textile Manufacturing Fiber to Complete Garments

Comprehensive Cost and Pricing Analysis for 1920s flapper dresses Sourcing

Understanding the Cost Components of 1920s Flapper Dresses

When sourcing authentic or reproduction 1920s flapper dresses, international B2B buyers must carefully analyze the detailed cost structure to make informed purchasing decisions. The key cost components include:

-

Materials: Fabric selection is critical. Typical materials range from silk and chiffon to sequined mesh and fringe trims, reflecting the era’s signature look. Natural fibers like silk increase costs but enhance authenticity and appeal in premium markets, while synthetic alternatives reduce price but may impact perceived value.

-

Labor: Labor costs vary widely depending on the manufacturing country. The intricate beadwork, fringe application, and embroidery common in flapper dresses require skilled artisans, which elevates labor costs. Regions with established garment industries (e.g., parts of Eastern Europe or South Asia) may offer competitive labor rates while maintaining quality.

-

Manufacturing Overhead: Overhead includes factory utilities, equipment maintenance, and administrative expenses. For flapper dresses, additional overhead may arise from specialized production lines for delicate fabrics and hand embellishments.

-

Tooling and Patterns: Initial investment in tooling, such as pattern making and sample development, can be significant. While these are often one-time costs amortized over large production runs, customized designs or limited editions increase this expense.

-

Quality Control (QC): Given the detailed workmanship flapper dresses demand, rigorous QC processes are essential. QC costs cover inspection staff, testing for material durability, and ensuring compliance with buyer specifications.

-

Logistics: International shipping, customs clearance, and insurance contribute to the landed cost. Flapper dresses are often lightweight but fragile, requiring protective packaging that may increase volumetric weight and shipping expenses.

-

Margins: Suppliers set margins based on market positioning, production scale, and buyer relationship. Higher margins can be expected for bespoke or small-batch orders.

Price Influencers Specific to 1920s Flapper Dress Sourcing

Several factors directly influence pricing dynamics:

-

Order Volume and Minimum Order Quantities (MOQ): Larger orders typically reduce per-unit costs due to economies of scale. However, many suppliers enforce MOQs that may be challenging for smaller distributors or niche retailers.

-

Customization and Specifications: Custom colors, unique bead patterns, or specific fabric blends raise costs. Buyers seeking historically accurate reproductions should anticipate premium pricing.

-

Material Quality and Certifications: Certified organic or ethically sourced fabrics command higher prices but appeal to markets with sustainability focus, increasingly relevant in Europe and parts of South America.

-

Supplier Location and Capabilities: Proximity to raw material sources or skilled labor pools affects pricing. For example, Eastern European manufacturers may offer a balance of quality and cost attractive to buyers in Poland and South Africa.

-

Incoterms: The choice between FOB, CIF, or DDP impacts who bears freight, insurance, and customs duties. Buyers must understand these terms to accurately calculate total procurement costs.

Strategic Buyer Tips for International Markets

To optimize sourcing costs while ensuring quality and timely delivery, B2B buyers from Africa, South America, the Middle East, and Europe should consider the following:

-

Negotiate on MOQ and Payment Terms: Engage suppliers in dialogue to reduce MOQs or stagger deliveries, mitigating inventory risk. Flexible payment terms can improve cash flow.

-

Evaluate Total Cost of Ownership (TCO): Beyond unit price, include logistics, customs, warehousing, and potential duties. For example, South African buyers should factor in import tariffs and local distribution costs.

-

Leverage Group Purchasing: Pooling orders with other buyers can unlock volume discounts and reduce per-unit costs.

-

Prioritize Proven Suppliers with Quality Certifications: Especially for European markets with strict import standards, selecting suppliers with certifications (e.g., ISO, OEKO-TEX) reduces compliance risks.

-

Understand Pricing Nuances by Region: For Middle Eastern buyers, consider cultural preferences influencing dress design and associated costs. South American buyers should be aware of currency fluctuations impacting pricing in USD or EUR.

-

Plan for Lead Times and Seasonal Demand: Flapper dresses may be seasonal; aligning orders to production cycles can secure better rates and avoid rush fees.

Disclaimer on Pricing

Indicative prices for 1920s flapper dresses vary significantly based on design complexity, materials, and order size. Buyers should request detailed quotations including all cost elements and verify supplier credentials before contract finalization. Market conditions and currency fluctuations may also impact final pricing.

This comprehensive cost and pricing framework equips international B2B buyers with the insights needed to strategically source 1920s flapper dresses, balancing authenticity, quality, and cost-efficiency across diverse global markets.

Spotlight on Potential 1920s flapper dresses Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘1920s flapper dresses’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for 1920s flapper dresses

Critical Technical Properties of 1920s Flapper Dresses for B2B Buyers

When sourcing 1920s flapper dresses, understanding the key technical specifications ensures product quality and market suitability. These properties influence manufacturing consistency, cost, and customer satisfaction across diverse international markets such as Africa, South America, the Middle East, and Europe.

Illustrative Image (Source: Google Search)

-

Fabric Composition and Grade

Flapper dresses typically use lightweight, flowing fabrics such as silk, chiffon, or rayon blends. The fabric grade—measured by thread count, fiber purity, and weight (gsm)—directly impacts durability and drape. For B2B buyers, specifying fabric grade ensures the final garment maintains the authentic 1920s look while meeting performance expectations in different climates and use cases. -

Hemline and Length Tolerances

Hemlines in flapper dresses varied but were characteristically shorter between 1926-1928, exposing the knee. Accurate hemline measurements with a tolerance of ±1 cm are crucial for historical accuracy and customer satisfaction. Buyers should confirm suppliers’ ability to maintain consistent hemlines to avoid returns and uphold brand reputation. -

Silhouette and Fit Specifications

The iconic straight, loose fit with suppressed bust and dropped waist defines the flapper dress silhouette. Specifying precise garment dimensions (bust, waist, hip, length) and acceptable fit tolerance is essential. This ensures that dresses reflect the masculine yet feminine aesthetic demanded by the market, and fit a broad range of body types internationally. -

Embroidery and Embellishment Quality

Many flapper dresses feature beading, sequins, or fringe. The quality, density, and attachment method of these embellishments affect both visual appeal and garment longevity. Buyers must verify embellishment standards, including bead size consistency and secure stitching, to guarantee durability during shipping and wear. -

Colorfastness and Dye Quality

Given the popularity of bold and pastel shades in the 1920s, colorfastness to washing and light exposure is vital. International buyers should request colorfastness test reports (e.g., ISO 105 standards) to avoid fading, especially when selling in sunny or humid climates. -

Packaging and Labeling Standards

Proper packaging preserves garment shape and embellishments during transit. Labeling must comply with destination country regulations, including fiber content, care instructions, and country of origin. Clear labeling supports customs clearance and builds consumer trust.

Key Trade Terminology for Efficient B2B Transactions

Understanding common industry terms facilitates smooth communication and negotiation between buyers and manufacturers or wholesalers, minimizing misunderstandings and delays.

-

OEM (Original Equipment Manufacturer)

Refers to a manufacturer who produces goods based on the buyer’s specifications and branding. For flapper dresses, OEM arrangements allow buyers to customize designs, labels, and packaging, essential for private label or boutique brands seeking differentiation. -

MOQ (Minimum Order Quantity)

The smallest number of units a supplier is willing to produce per order. MOQs impact inventory planning and cost efficiency. Buyers from emerging markets or smaller enterprises should negotiate MOQs that balance affordability with production viability. -

RFQ (Request for Quotation)

A formal inquiry sent by the buyer to suppliers requesting detailed pricing, lead times, and terms. An RFQ should include technical specs and order volumes to obtain accurate and comparable quotes, enabling informed sourcing decisions. -

Incoterms (International Commercial Terms)

Standardized trade terms (e.g., FOB, CIF, EXW) that define responsibilities for shipping, insurance, and customs. Understanding Incoterms helps buyers clarify cost and risk distribution during international transport, crucial for regions with complex logistics like Africa or South America. -

Lead Time

The total time from order placement to delivery. Accurate lead time estimates help buyers plan inventory and marketing launches. For flapper dresses, lead times may vary depending on embellishment complexity and shipping routes. -

Quality Control (QC)

Procedures and checkpoints to ensure garments meet agreed standards before shipment. Buyers should specify QC criteria and request inspection reports to reduce defects and returns, especially important for delicate fabrics and intricate detailing typical of flapper dresses.

Mastering these technical properties and trade terms empowers international B2B buyers to source authentic, high-quality 1920s flapper dresses efficiently, catering to diverse markets while managing cost, quality, and compliance effectively.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the 1920s flapper dresses Sector

Market Overview & Key Trends

The global market for 1920s flapper dresses remains a niche yet vibrant segment within vintage-inspired and period-specific fashion. International B2B buyers from regions such as Africa, South America, the Middle East, and Europe (including Poland and South Africa) are witnessing a steady demand driven by cultural events, theatrical productions, luxury fashion revivals, and themed hospitality sectors. The appeal of flapper dresses lies in their iconic design—characterized by straight, loose silhouettes, dropped waists, and decorative embellishments such as sequins and fringes—which resonate with clients seeking authentic vintage aesthetics blended with modern production efficiencies.

Key market drivers include the resurgence of interest in 1920s culture, jazz festivals, and retro-themed parties across global urban centers. Additionally, the rise of digital marketing platforms and B2B marketplaces enables easier sourcing of authentic or reproduction flapper dresses, facilitating cross-border transactions. Buyers from emerging markets like South America and Africa are increasingly exploring collaborations with manufacturers in Europe and Asia, leveraging improved logistics and trade agreements.

Illustrative Image (Source: Google Search)

Technological advancements in textile production, including digital printing and automated embroidery, are allowing manufacturers to replicate intricate flapper dress details at scale without compromising on craftsmanship. For B2B buyers, this means access to customizable options with shorter lead times. Moreover, sourcing trends are shifting towards hybrid supply chains that combine artisanal handwork with mechanized processes, ensuring both authenticity and cost efficiency.

Market dynamics are also influenced by regulatory environments and trade policies, particularly in regions such as the Middle East where import tariffs and compliance standards can impact sourcing decisions. Buyers should prioritize suppliers with transparent supply chains and certifications to mitigate risks. The growing importance of omnichannel retailing in Europe and South America encourages bulk purchasing for resale, rental, or event use, emphasizing the need for reliable, scalable sourcing partners.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a critical factor for B2B buyers in the 1920s flapper dress sector, driven by increasing environmental awareness and consumer demand for ethical fashion. The production of vintage-style dresses often involves materials such as silk, rayon, and synthetic embellishments, which can have significant environmental footprints if sourced irresponsibly. For international buyers, especially those in Europe and South Africa, aligning with suppliers who demonstrate commitment to sustainable practices is not only a regulatory safeguard but also a competitive advantage.

Ethical sourcing involves ensuring fair labor practices, transparency in supply chains, and minimizing chemical usage in fabric dyeing and finishing processes. Buyers should seek out manufacturers certified under recognized standards such as OEKO-TEX®, Global Organic Textile Standard (GOTS), or Fair Trade certifications, which guarantee the absence of harmful substances and adherence to social responsibility.

Materials innovation is also reshaping sourcing strategies. Sustainable alternatives like organic cotton blends, recycled polyester, and low-impact dyes are increasingly incorporated into flapper dress production without sacrificing the visual authenticity of the 1920s style. Suppliers offering biodegradable packaging and carbon-neutral shipping options further enhance the sustainability profile.

For buyers in emerging markets, partnering with suppliers who invest in community development and environmental stewardship can resonate well with local market values and international sustainability commitments. Establishing long-term supplier relationships based on shared sustainability goals reduces supply chain disruptions and supports brand reputation.

Illustrative Image (Source: Google Search)

Brief Evolution & Historical Context

The 1920s flapper dress emerged as a symbol of social liberation and modernity following the upheavals of World War I. Characterized by a straight, loose fit with dropped waistlines, the dress diverged sharply from the restrictive fashions of previous decades, reflecting the new feminine silhouette that embraced freedom of movement and youthfulness. The flapper style peaked between 1926 and 1928, featuring knee-length hemlines, intricate beadwork, and fringe detailing that captured the exuberance of the Jazz Age.

This fashion democratization was supported by simplified dressmaking techniques and mass-produced patterns, making flapper dresses accessible beyond elite circles—a trend that informs today’s sourcing strategies focused on scalability and affordability. Understanding this historical evolution helps B2B buyers appreciate the balance between authenticity and modern production efficiencies when selecting suppliers and designing collections.

Frequently Asked Questions (FAQs) for B2B Buyers of 1920s flapper dresses

-

How can I effectively vet suppliers of 1920s flapper dresses to ensure quality and reliability?

Start by requesting detailed product catalogs and samples to verify fabric quality, stitching, and authenticity of design. Check supplier certifications such as ISO or compliance with international textile standards. Research their production capacity and years in business, and seek references or reviews from other B2B buyers, particularly those in your region. Utilize third-party inspection services if necessary. A thorough vetting process reduces risks of substandard products and delivery delays, which is critical when importing into diverse markets like Africa, South America, and Europe. -

Is customization of 1920s flapper dresses available for bulk orders, and what are typical options?

Many manufacturers offer customization including fabric choice, embellishments (beading, fringes), sizing adjustments, and color variations to suit local market preferences. When negotiating, clarify minimum order quantities (MOQs) for custom designs and lead times required for sample approval and production. Customization can add value and differentiate your offerings but may require longer lead times. Ensure clear communication on design specifications and confirm prototypes before full production to avoid costly errors. -

What are common minimum order quantities (MOQs) and lead times for sourcing 1920s flapper dresses internationally?

MOQs typically range from 50 to 200 pieces per style, depending on the supplier’s scale and customization level. Lead times usually span 30 to 60 days from order confirmation, including sample approval. For buyers in regions like the Middle East or South America, factor in additional shipping time and customs clearance. Planning orders well in advance and consolidating shipments can optimize costs and ensure timely inventory replenishment. -

Which payment terms are most secure and commonly accepted in international B2B transactions for vintage-inspired apparel?

Suppliers often require a 30% deposit upfront with the balance payable before shipment or upon delivery. Letters of credit (LC) or escrow services provide added security for large orders. For trusted partners, net 30 or net 60 terms may be negotiated. Always confirm payment terms in writing within contracts and avoid full upfront payments without verified supplier credibility. Using reputable trade platforms and escrow can safeguard funds and encourage transparent transactions. -

What quality assurance (QA) measures should I insist on when importing 1920s flapper dresses?

Request detailed quality control checkpoints during production, including fabric inspection, seam strength testing, and embellishment durability. Require suppliers to provide inspection reports and photos at various stages. Hiring third-party inspectors for pre-shipment audits is advisable, especially for large orders. Establish clear defect tolerance levels and return policies in contracts. Rigorous QA prevents returns and protects your brand reputation in competitive international markets. -

Are there specific certifications or compliance standards relevant for flapper dresses in global markets?

While no unique certifications apply specifically to 1920s flapper dresses, general textile and apparel standards such as OEKO-TEX (certifying absence of harmful substances) and ISO 9001 (quality management) are important. Compliance with import regulations and labeling standards in your target market (e.g., EU textile labeling laws, South African Bureau of Standards) is essential. Verify that suppliers comply with labor and environmental standards to meet increasing buyer and consumer expectations globally. -

What logistics considerations are crucial for shipping flapper dresses to Africa, South America, or Europe?

Choose freight modes balancing cost and speed—sea freight is economical for large shipments but slower; air freight suits urgent orders but costs more. Understand customs duties, import taxes, and documentation requirements for your destination country to avoid clearance delays. Consolidate shipments to reduce costs and use reliable freight forwarders familiar with local regulations. Packaging should protect delicate embellishments during transit. Regular communication with suppliers and logistics partners ensures smooth delivery. -

How should disputes over quality or delivery delays be handled in international B2B contracts?

Include clear dispute resolution clauses in contracts specifying arbitration venues, governing law, and timelines for claims. Maintain detailed records of communications, contracts, and quality inspections. Promptly notify suppliers of any issues with supporting evidence. Negotiate remedies such as refunds, replacements, or discounts upfront. Employ mediation or arbitration services if informal resolution fails. A proactive approach to dispute management minimizes financial risks and preserves long-term supplier relationships.

Strategic Sourcing Conclusion and Outlook for 1920s flapper dresses

The enduring appeal of 1920s flapper dresses lies in their iconic blend of historic authenticity and contemporary adaptability. For international B2B buyers, especially those in Africa, South America, the Middle East, and Europe, strategic sourcing of these garments presents a unique opportunity to capitalize on a niche market that values both vintage style and modern production efficiencies.

Key takeaways for sourcing success include prioritizing suppliers who understand the nuanced design elements—such as the characteristic drop waist, flat chest silhouette, and distinctive hemlines—that define authentic flapper fashion. Leveraging manufacturers skilled in quality fabric selection and streamlined garment construction can reduce lead times and costs, making these dresses more accessible across diverse markets. Furthermore, aligning with suppliers experienced in scalable production can help meet fluctuating demand while maintaining product integrity.

Looking ahead, buyers are encouraged to embrace strategic partnerships that foster innovation, sustainability, and cultural relevance. By integrating these principles into their sourcing strategy, businesses can not only satisfy growing consumer interest but also enhance brand positioning in global fashion landscapes. The 1920s flapper dress market offers vibrant potential—now is the time to act decisively and secure competitive advantage through informed, strategic sourcing.