Master Sourcing Wrap Dress Patterns: A B2B Guide for Global

Guide to Wrap Dress Pattern

- Introduction: Navigating the Global Market for wrap dress pattern

- Understanding wrap dress pattern Types and Variations

- Key Industrial Applications of wrap dress pattern

- Strategic Material Selection Guide for wrap dress pattern

- In-depth Look: Manufacturing Processes and Quality Assurance for wrap dress pattern

- Comprehensive Cost and Pricing Analysis for wrap dress pattern Sourcing

- Spotlight on Potential wrap dress pattern Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for wrap dress pattern

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the wrap dress pattern Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of wrap dress pattern

- Strategic Sourcing Conclusion and Outlook for wrap dress pattern

Introduction: Navigating the Global Market for wrap dress pattern

The global demand for wrap dress patterns continues to surge as fashion markets evolve and diversify across continents. For international B2B buyers—especially those operating in dynamic regions such as Africa, South America, the Middle East, and Europe—understanding the nuances of sourcing wrap dress patterns is crucial. These patterns are not only foundational for creating versatile, flattering garments but also serve as a strategic entry point into fashion manufacturing and retail sectors that prioritize adaptability and consumer appeal.

Wrap dress patterns offer a unique combination of design flexibility and scalability, making them a highly sought-after commodity. Their inherent adaptability to various fabrics, styles, and body types positions them as a staple in both traditional and contemporary apparel lines. For buyers, this translates into opportunities to cater to diverse markets with culturally tailored fashion while maintaining cost efficiency.

This comprehensive guide covers every critical aspect to empower your sourcing strategy, including:

- Pattern Types & Customization: Explore styles ranging from classic to modern, with insights on tailoring for regional preferences.

- Material Selection: Guidance on fabric compatibility to ensure quality, durability, and market relevance.

- Manufacturing & Quality Control: Best practices for overseeing production processes that meet international standards.

- Supplier Evaluation: Criteria to identify reliable, ethical manufacturers with proven capabilities.

- Cost Analysis & Market Trends: Understand pricing structures and emerging demands within key global markets.

- Frequently Asked Questions: Address common concerns and challenges faced by B2B buyers.

By leveraging this knowledge, buyers from Egypt to Mexico can make informed decisions that optimize supply chain efficiency, minimize risks, and maximize profitability in the competitive fashion landscape. This guide is your strategic partner in navigating the complexities of the wrap dress pattern market worldwide.

Understanding wrap dress pattern Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Classic Wrap Dress | Front wrap closure with tie belt, V-neckline | Mass-market apparel, boutique collections | Versatile and flattering; may require precise sizing |

| Faux Wrap Dress | Wrap illusion with fixed seams, no actual wrap closure | Ready-to-wear lines, fast fashion | Easier to produce; less adjustable for fit |

| Maxi Wrap Dress | Full-length wrap style, often flowy fabrics | Seasonal collections, luxury and resort wear | Elegant and high demand; higher fabric cost and complexity |

| Wrap Dress with Sleeves | Incorporates varied sleeve styles (long, puff, bell) | Diverse markets, including modest fashion segments | Adds style variety; may increase production complexity |

| Asymmetric Wrap Dress | Irregular hemline or wrap overlap, modern aesthetic | Trend-driven collections, fashion-forward brands | Unique appeal; may limit broad market acceptance |

Classic Wrap Dress

The classic wrap dress is the archetype featuring a front wrap closure secured by a tie belt and a flattering V-neckline. It suits a wide range of body types, making it a staple for mass-market and boutique apparel lines. For B2B buyers, this pattern promises broad consumer appeal but demands attention to sizing accuracy to minimize returns and maximize customer satisfaction. It is a reliable choice for brands emphasizing timeless elegance and versatility.

Faux Wrap Dress

Faux wrap dresses simulate the wrap style with fixed seams instead of an actual wrap closure. This variation is popular in ready-to-wear and fast fashion sectors due to simplified manufacturing processes and reduced fitting challenges. Buyers benefit from lower production costs and faster turnaround times. However, the lack of adjustability can affect customer comfort and fit, which must be considered when targeting markets with diverse body types.

Maxi Wrap Dress

Maxi wrap dresses extend the classic design into full-length garments, often crafted with flowy, luxurious fabrics. These are ideal for seasonal collections, resort wear, and premium market segments in Europe, the Middle East, and affluent areas of South America. While they offer elegance and high consumer demand, buyers should account for increased fabric usage and more complex production, impacting cost and supply chain logistics.

Wrap Dress with Sleeves

Adding sleeves in various styles—such as long, puffed, or bell-shaped—expands the wrap dress’s appeal to diverse markets, including modest fashion sectors prevalent in the Middle East and parts of Africa. This variation supports seasonal adaptability and style differentiation. For B2B buyers, incorporating sleeve options can open new market segments but may introduce additional pattern grading and manufacturing complexity.

Asymmetric Wrap Dress

Asymmetric wrap dresses feature irregular hemlines or wrap overlaps, catering to fashion-forward brands aiming for unique, contemporary aesthetics. This style resonates well in trend-driven markets across Europe and cosmopolitan urban centers globally. While offering a distinctive edge, buyers should consider potential limitations in mass-market acceptance and the need for specialized pattern grading and quality control to maintain design integrity.

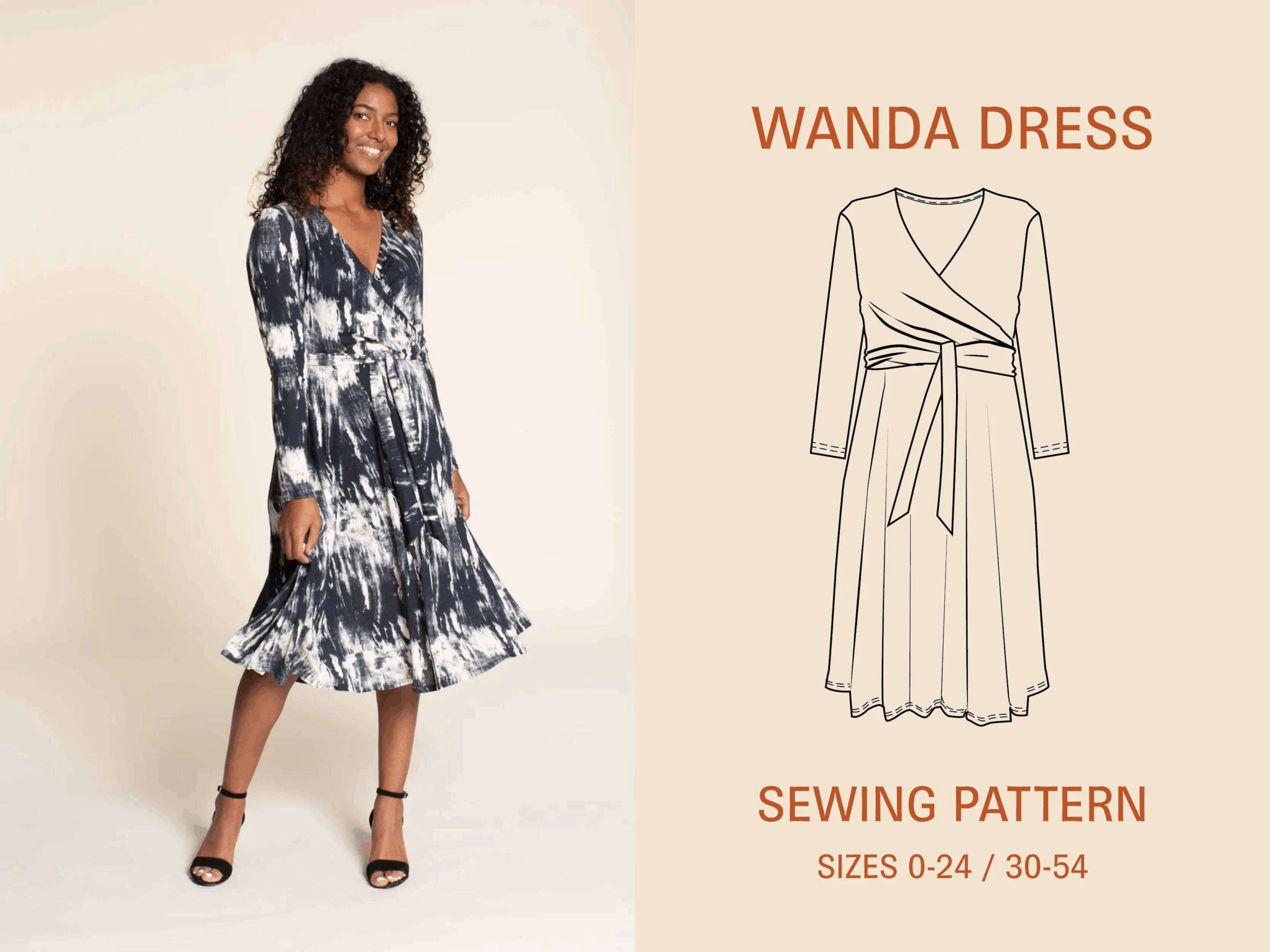

Related Video: TOP 20 BEST WRAP DRESS PATTERNS YOU NEED TO TRY! (Woven)

Key Industrial Applications of wrap dress pattern

| Industry/Sector | Specific Application of wrap dress pattern | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Apparel Manufacturing | Production of versatile, size-inclusive women’s wear | Enhances product range with adaptable, flattering designs | Fabric quality, pattern adaptability, cultural fit, and ease of mass production |

| Fashion Retail & Wholesale | Ready-to-wear collections featuring wrap dresses | Meets diverse consumer demand, boosts seasonal sales | Supplier reliability, pattern consistency, regional style preferences |

| Textile & Fabric Suppliers | Development of fabric collections tailored for wrap dresses | Drives fabric demand through targeted product lines | Fabric durability, drape characteristics, and sustainability certifications |

| Costume & Uniform Design | Custom wrap dress patterns for hospitality and corporate uniforms | Combines style with functionality for brand identity | Comfort, ease of wear, customization options, and regulatory compliance |

| E-commerce & DIY Sewing Kits | Offering wrap dress patterns with materials for home sewing | Expands market reach through DIY trend and personalization | Clear instructions, pattern scalability, and packaging quality |

Apparel Manufacturing

Wrap dress patterns are essential in apparel manufacturing for producing versatile and size-inclusive women’s clothing lines. They allow manufacturers to create garments that flatter a wide range of body types, which is particularly important in diverse markets such as Africa, South America, and the Middle East. For international buyers, sourcing patterns that can be easily adapted to different fabric types and production scales ensures efficient manufacturing processes and reduces waste. Prioritizing patterns that accommodate regional sizing and style preferences helps manufacturers better serve local markets.

Fashion Retail & Wholesale

Retailers and wholesalers leverage wrap dress patterns to develop ready-to-wear collections that appeal to a broad consumer base. The adjustable nature of wrap dresses allows for flexibility in fit and style, making them a popular choice across various climates and cultural contexts, from Europe to Egypt and Mexico. Buyers should focus on sourcing patterns with proven consistency and scalability to maintain quality across large production runs. Additionally, understanding regional fashion trends and seasonality can optimize inventory and sales performance.

Textile & Fabric Suppliers

Fabric suppliers play a pivotal role by offering textiles specifically suited for wrap dress production. The pattern’s reliance on fabric drape and comfort means suppliers must provide materials that hold shape yet allow movement, such as lightweight cottons, silks, or jersey knits. For B2B buyers in emerging markets, sourcing fabrics with sustainability certifications or biogenic content testing can add value and meet increasing regulatory demands. Collaborating with pattern designers to align fabric properties with dress designs enhances the end product’s appeal.

Costume & Uniform Design

In the hospitality and corporate sectors, wrap dress patterns are adapted for stylish yet functional uniforms. These garments must balance comfort, ease of wear, and brand identity, making the wrap dress an ideal choice. International buyers should seek patterns that allow for customization, such as adjustable closures and varied sleeve options, to accommodate different climates and workplace requirements. Compliance with local labor and safety regulations is critical when selecting these patterns for uniform production.

E-commerce & DIY Sewing Kits

The rising trend of DIY fashion has opened opportunities for e-commerce businesses to offer wrap dress patterns bundled with fabrics and sewing materials. This appeals to consumers worldwide seeking personalized garments, including markets in South America and Europe. For B2B buyers supplying these kits, it is vital to source patterns that come with clear, multilingual instructions and scalable sizing options. Packaging quality and ease of use can differentiate products in competitive online marketplaces and foster customer loyalty.

Related Video: LABORATORY APPARATUS AND THEIR USES

Strategic Material Selection Guide for wrap dress pattern

When selecting materials for wrap dress patterns, international B2B buyers must consider fabric properties that influence garment performance, manufacturing efficiency, and market preferences. The choice of material affects the dress’s drape, comfort, durability, and suitability for different climates and occasions. Below is an analysis of four common fabric types used in wrap dresses, focusing on their key properties, advantages, limitations, and regional considerations for buyers from Africa, South America, the Middle East, and Europe.

Cotton

Key Properties:

Cotton is a natural fiber known for its breathability, moisture absorption, and softness. It performs well in warm climates due to its cooling effect and is generally easy to dye and print. Cotton fabrics vary widely in weight and weave, affecting durability and drape.

Pros & Cons:

Cotton is durable, comfortable, and hypoallergenic, making it suitable for everyday wear. It is relatively low-cost and widely available, which benefits large-scale manufacturing. However, cotton wrinkles easily and can shrink if not pre-treated, requiring careful handling during production.

Impact on Application:

Cotton wrap dresses are ideal for casual and semi-formal wear, especially in hot and humid regions like parts of Africa and South America. Its moisture-wicking ability supports comfort in warm climates but may not be optimal for colder regions without layering.

Regional Considerations:

Buyers in Egypt and Mexico will find cotton fabrics compliant with widely accepted standards such as ASTM D123 and ISO 105 for colorfastness. Sustainable sourcing and organic cotton are increasingly valued in European markets, aligning with WRAP certification and ethical sourcing requirements. Cotton’s biodegradability also appeals to environmentally conscious buyers globally.

Polyester

Key Properties:

Polyester is a synthetic fiber prized for its strength, wrinkle resistance, and quick-drying properties. It maintains shape well and resists shrinking and stretching, providing durability in finished garments.

Pros & Cons:

Polyester is cost-effective and easy to care for, making it attractive for mass production. It is less breathable than natural fibers, which can reduce comfort in hot climates. Additionally, polyester is prone to static buildup and may have a less luxurious hand feel compared to natural fibers.

Impact on Application:

Polyester wrap dresses are suitable for workwear or travel garments where wrinkle resistance and durability are priorities. They perform well in cooler or temperate climates common in Europe and the Middle East but may require blends with natural fibers to improve comfort in tropical regions.

Regional Considerations:

International buyers should ensure polyester fabrics meet Oeko-Tex Standard 100 or REACH regulations, especially for export to Europe. In markets like South America and Africa, cost sensitivity favors polyester blends. Compliance with ASTM D3787 for abrasion resistance is also relevant for quality assurance.

Rayon (Viscose)

Key Properties:

Rayon is a semi-synthetic fiber made from regenerated cellulose, offering a silk-like appearance and excellent drape. It is breathable and comfortable but less durable than cotton or polyester.

Pros & Cons:

Rayon provides a luxurious feel and vibrant color uptake, making it popular for stylish, flowy wrap dresses. However, it wrinkles easily and can weaken when wet, increasing manufacturing complexity. It also requires careful washing instructions, which may affect consumer satisfaction.

Impact on Application:

Rayon is favored for fashion-forward markets where aesthetic appeal is paramount. It suits moderate climates and indoor wear but may not be ideal for heavy-duty or outdoor use. Blends with polyester or cotton can improve durability and ease of care.

Regional Considerations:

Buyers from Europe and the Middle East should verify compliance with EU textile labeling regulations and chemical safety standards. In Africa and South America, sourcing rayon from suppliers with sustainable practices is increasingly important to meet ethical trade expectations.

Linen

Key Properties:

Linen is a natural fiber derived from flax, known for its exceptional breathability and moisture-wicking properties. It is strong and becomes softer with use but wrinkles more than cotton.

Pros & Cons:

Linen offers a premium, textured look suitable for high-end wrap dresses. It is highly durable and ideal for hot climates but is more expensive and can be challenging to manufacture due to its stiffness and tendency to crease.

Impact on Application:

Linen wrap dresses are excellent for summer collections targeting upscale markets in Europe and the Middle East. Its natural cooling effect suits buyers in hot regions like Egypt and Mexico. However, linen’s higher cost and care requirements limit its use in budget-conscious markets.

Regional Considerations:

Compliance with OEKO-TEX and GOTS certifications enhances linen’s appeal in Europe and among ethical buyers globally. Its natural origin aligns with sustainability trends, but buyers should consider supply chain transparency and seasonal availability when sourcing.

| Material | Typical Use Case for wrap dress pattern | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Cotton | Casual and semi-formal wrap dresses for warm climates | Breathable, comfortable, widely available | Prone to wrinkling and shrinkage if untreated | Low |

| Polyester | Workwear and travel-friendly wrap dresses requiring durability | Wrinkle-resistant, durable, cost-effective | Less breathable, may feel synthetic | Low to Medium |

| Rayon (Viscose) | Fashion-forward, flowy wrap dresses with elegant drape | Luxurious feel and excellent drape | Wrinkles easily, weaker when wet | Medium |

| Linen | Premium summer wrap dresses for upscale markets | Highly breathable, durable, natural texture | Expensive, wrinkles easily, manufacturing challenges | High |

This guide assists B2B buyers in selecting fabrics that align with their target markets’ climate, consumer preferences, and regulatory requirements. Considering the balance between cost, performance, and sustainability is essential for successful wrap dress production and international trade.

In-depth Look: Manufacturing Processes and Quality Assurance for wrap dress pattern

Manufacturing and quality assurance of wrap dress patterns involve a series of carefully controlled steps to ensure product consistency, fit accuracy, and durability. For international B2B buyers—especially those operating in markets like Africa, South America, the Middle East, and Europe—understanding these processes and quality control mechanisms is crucial for selecting reliable suppliers and maintaining brand standards.

Manufacturing Process Overview for Wrap Dress Patterns

The production of wrap dress patterns typically follows four main stages: material preparation, pattern forming, assembly, and finishing. Each stage incorporates specific techniques to ensure precision and quality.

1. Material Preparation

- Fabric Selection and Inspection: The process begins with sourcing appropriate fabrics, often lightweight or medium-weight materials such as cotton blends, silk, or jersey knits. Suppliers conduct fabric quality inspections for defects, colorfastness, shrinkage, and hand feel.

- Pre-treatment: Depending on fabric type, pre-shrinking, washing, or chemical treatments (e.g., anti-wrinkle finishes) may be applied to stabilize the fabric and enhance performance.

- Cutting Preparation: Fabric rolls are inspected, aligned, and laid out on cutting tables, with careful attention to grain direction and fabric pattern orientation to ensure the wrap dress’s flattering silhouette.

2. Pattern Forming and Cutting

- Pattern Digitization: Modern manufacturers use CAD (Computer-Aided Design) systems to digitize and grade wrap dress patterns across multiple sizes. This ensures consistency and scalability.

- Marker Making: Efficient layout of pattern pieces on fabric (marker) is optimized to reduce waste.

- Cutting Techniques: Automated cutting machines (e.g., laser cutters, straight knife cutters) or skilled manual cutting are employed. Precision is critical to maintain seam allowances and fit accuracy.

3. Assembly and Sewing

- Sewing Operations: The assembly involves stitching together bodice pieces, sleeves, waist ties, and skirt portions. Key techniques include overlocking for seam finishes, flat seams for comfort, and reinforced stitching in high-stress areas such as ties and waistbands.

- Fitting Adjustments: Some manufacturers incorporate in-line fitting assessments to ensure the wrap dress maintains its adjustable and flattering design.

- Special Features: Depending on the pattern, additional details like ruffles, pleats, or buttonholes may be sewn during this stage.

4. Finishing

- Quality Stitching Inspection: Final seams are checked for uniformity and strength.

- Pressing and Folding: Garments are pressed to enhance appearance and packaged carefully to avoid creasing.

- Labeling and Packaging: Compliance with labeling standards (country of origin, fabric content, care instructions) is verified before shipment.

Quality Assurance and Control (QA/QC) in Wrap Dress Pattern Manufacturing

For B2B buyers, robust QA/QC practices ensure that wrap dresses meet performance, safety, and aesthetic standards. Suppliers often align with international and industry-specific standards to satisfy diverse market requirements.

Relevant International Standards

- ISO 9001 (Quality Management Systems): A foundational certification indicating the supplier’s commitment to systematic quality management and continuous improvement.

- OEKO-TEX® Standard 100: Ensures fabrics are free from harmful substances, a critical factor for apparel buyers concerned about consumer safety.

- WRAP (Worldwide Responsible Accredited Production): Ethical manufacturing certification focusing on lawful, humane, and ethical production, particularly important for buyers emphasizing social compliance.

- CE Marking (where applicable): Although typically for safety-related products, certain apparel accessories or components might require CE certification in European markets.

QC Checkpoints in Manufacturing

- Incoming Quality Control (IQC): Inspection of raw materials including fabric, threads, and trims to detect defects or inconsistencies before production.

- In-Process Quality Control (IPQC): Regular monitoring during sewing and assembly stages, including seam strength tests, dimensional checks, and fit assessments.

- Final Quality Control (FQC): Comprehensive review of finished garments for defects such as incorrect stitching, fabric flaws, measurement deviations, and labeling accuracy.

Common Testing Methods

- Dimensional and Fit Testing: Ensures patterns produce garments meeting specified size charts.

- Colorfastness Testing: Validates resistance to washing, rubbing, and light exposure, critical for maintaining appearance in diverse climates.

- Tensile Strength and Seam Integrity Tests: Measure durability of stitches and fabric under stress.

- Chemical Testing: Screens for restricted substances, ensuring compliance with international safety norms.

- Visual Inspections: Detect aesthetic defects such as stains, misaligned patterns, or inconsistent finishes.

How B2B Buyers Can Verify Supplier Quality Controls

Ensuring your supplier maintains rigorous QC standards involves proactive due diligence and continuous monitoring:

- Factory Audits: Conduct or commission on-site audits focusing on quality management systems, ethical practices, and production capabilities. Third-party audit firms specializing in textile and garment manufacturing can provide objective assessments.

- Review of QC Documentation: Request access to inspection reports, test certificates (e.g., OEKO-TEX®, WRAP), and ISO 9001 certification evidence.

- Third-Party Inspections: Engage independent inspectors to perform random sampling and testing of products before shipment. This is especially recommended for buyers importing into Europe or countries with stringent import regulations.

- Sample Approvals: Obtain and approve pre-production and production samples to verify pattern accuracy, fabric quality, and finishing standards.

- Supplier Scorecards: Develop performance metrics based on defect rates, delivery punctuality, and responsiveness to quality issues to track supplier reliability over time.

QC and Certification Nuances for International B2B Buyers in Emerging and Diverse Markets

Buyers from Africa, South America, the Middle East, and Europe face specific considerations when sourcing wrap dress patterns internationally:

- Regulatory Compliance: Different countries may impose unique import regulations, labeling requirements, or chemical restrictions. For example, the EU enforces REACH regulations limiting hazardous chemicals, while Middle Eastern markets may emphasize modesty compliance in garment design.

- Cultural Preferences: Quality inspections should also account for regional style preferences, such as sleeve length or fabric opacity, ensuring the wrap dress pattern aligns with market expectations.

- Ethical Sourcing Emphasis: African and South American buyers increasingly prioritize suppliers with WRAP or similar certifications to support ethical labor practices and sustainability.

- Logistics and Communication: Time zone differences and language barriers can affect quality oversight. Leveraging local quality consultants or inspection agencies can mitigate risks.

- Cost-Quality Balance: Buyers must balance cost constraints with the need for durable, well-fitting garments. Investing in suppliers with proven QC processes reduces costly returns and brand damage.

- Trade Agreements and Certifications: Awareness of bilateral trade agreements (e.g., EU-Mexico Free Trade Agreement) can influence supplier selection by facilitating smoother customs clearance and ensuring compliance with local standards.

Summary for B2B Buyers

Selecting a wrap dress pattern manufacturer with robust manufacturing processes and rigorous quality assurance practices is essential to delivering consistent, high-quality garments to your market. Focus on suppliers who:

- Utilize advanced cutting and sewing technologies combined with skilled craftsmanship.

- Hold internationally recognized certifications such as ISO 9001 and WRAP.

- Implement comprehensive QC at every production stage (IQC, IPQC, FQC).

- Provide transparent documentation and allow third-party inspections.

- Understand and adapt to regional regulatory and cultural requirements.

By prioritizing these factors, B2B buyers in Africa, South America, the Middle East, and Europe can secure reliable partnerships that support scalable production, brand integrity, and customer satisfaction in the competitive apparel market.

Related Video: Garments Full Production Process | Order receive to Ex-Factory | Episode 2

Comprehensive Cost and Pricing Analysis for wrap dress pattern Sourcing

When sourcing wrap dress patterns for B2B purposes, understanding the detailed cost structure and pricing dynamics is critical to making informed purchasing decisions. This insight is particularly vital for buyers from diverse regions such as Africa, South America, the Middle East, and Europe, where logistical and market conditions vary significantly.

Key Cost Components in Wrap Dress Pattern Sourcing

-

Materials

The fabric quality and type directly impact costs. Common choices include cotton, silk, jersey, or blends, each with different price points. Pattern paper, printing materials, and packaging also add to material costs. For buyers prioritizing sustainable sourcing, certified eco-friendly fabrics may increase costs but add value. -

Labor

Skilled labor for pattern drafting, grading, and sampling is a major cost driver. Labor costs vary widely by country and region, influencing final pricing. For example, sourcing from countries with lower labor costs can reduce expenses but may require scrutiny to maintain quality standards. -

Manufacturing Overhead

This includes factory utilities, equipment depreciation, and indirect labor. Efficient factories with modern technology often have higher overhead but can offer better quality and faster turnaround. -

Tooling and Development

Initial pattern development, including prototyping and adjustments, incurs tooling costs. Custom or complex wrap dress designs increase these expenses, whereas standard or bulk patterns lower them.

-

Quality Control (QC)

QC processes are essential to ensure pattern accuracy and garment fit. Costs here cover inspections, testing, and possible rework. Certifications such as WRAP or ISO can add assurance but may elevate costs. -

Logistics and Freight

Shipping expenses depend on the shipment mode (air, sea, or land), distance, and customs duties. Buyers from Egypt, Mexico, or other regions should factor in import taxes and potential delays that could affect delivery schedules and costs. -

Supplier Margin

Suppliers incorporate margins to cover risks and profit. Negotiating favorable terms often depends on order volume and long-term partnerships.

Influential Pricing Factors

-

Order Volume / Minimum Order Quantity (MOQ)

Larger volumes generally lead to price breaks. Buyers should balance MOQ requirements with inventory capacity and demand forecasts. -

Pattern Specifications and Customization

Custom wrap dress patterns tailored to brand requirements increase costs. Off-the-shelf designs are more cost-effective but less unique. -

Material Selection

Higher-end fabrics or specialized prints elevate prices. Consider fabric availability in the supplier’s region to avoid premium import costs. -

Quality and Certifications

Ethical sourcing certifications (e.g., WRAP) or compliance with international standards add credibility and may justify higher pricing. -

Supplier Location and Reliability

Proximity to the buyer reduces shipping costs and lead times. Established suppliers with proven track records may charge premium prices but reduce risk. -

Incoterms

Understanding terms like FOB, CIF, or DDP is vital. Each impacts who bears shipping, insurance, and customs costs, affecting the total landed cost.

Strategic Tips for International B2B Buyers

-

Negotiate Based on Total Cost of Ownership (TCO):

Go beyond unit price. Factor in logistics, customs, potential delays, and quality assurance expenses. For example, a slightly higher price from a supplier closer to Egypt or Mexico may save overall costs through reduced freight and faster delivery. -

Leverage Volume Discounts and Long-Term Contracts:

Securing favorable pricing often requires committing to larger volumes or multi-year agreements, which also stabilizes supply. -

Prioritize Suppliers with Transparent Cost Breakdowns:

This enables pinpointing cost-saving opportunities, such as switching to alternative materials or adjusting specifications. -

Assess Currency Fluctuations and Payment Terms:

Currency volatility can impact final costs. Negotiate flexible payment terms or currency hedging options to mitigate risks. -

Understand Regional Import Regulations:

Customs duties and compliance requirements vary widely, especially for buyers in South America and the Middle East. Early engagement with customs brokers can prevent costly surprises. -

Evaluate Quality vs. Price Trade-offs:

While lower prices are attractive, substandard patterns can increase returns and production waste. Prioritize suppliers offering certifications and proven quality.

Indicative Pricing Disclaimer

Prices for wrap dress patterns can vary significantly based on the factors outlined above. The figures provided by suppliers should be considered indicative and subject to detailed negotiation. International buyers are encouraged to request comprehensive quotations including all ancillary costs to accurately assess sourcing viability.

By carefully analyzing these cost and pricing components, international B2B buyers can optimize their sourcing strategy for wrap dress patterns, ensuring competitive pricing without compromising on quality or delivery reliability.

Spotlight on Potential wrap dress pattern Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘wrap dress pattern’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for wrap dress pattern

When sourcing wrap dress patterns, understanding the essential technical properties and trade terminology is crucial for making informed purchasing decisions. This knowledge ensures product quality, efficient communication with suppliers, and smooth international transactions.

Key Technical Properties of Wrap Dress Patterns

1. Fabric Compatibility and Material Grade

The pattern should specify the types of fabrics suitable for the design, such as cotton blends, jersey knits, or silk. Material grade indicates the quality level of recommended fabrics, influencing the garment’s drape, durability, and comfort. For B2B buyers, confirming fabric compatibility helps avoid costly mismatches and ensures the final product meets market expectations across diverse climates and preferences, such as those in Africa or Europe.

2. Pattern Size Range and Grading Tolerance

A wrap dress pattern must cover an appropriate size range, typically from XS to XL or plus sizes, depending on target markets. Grading tolerance refers to the permissible variation in measurements between sizes, usually within 1-2 cm. This tolerance impacts fit consistency and customer satisfaction, so buyers should verify these specifications to reduce returns and increase brand loyalty.

3. Seam Allowance Specifications

Seam allowance is the extra fabric included around pattern pieces to allow for sewing. Standard allowances are often 1 cm to 1.5 cm but can vary. Clear specification ensures that manufacturers understand how much fabric to allocate and maintain structural integrity during production, crucial for scalable manufacturing.

4. Pattern Piece Count and Complexity

The number of pattern pieces affects production time and cost. Simple wrap dress patterns may have 5-7 pieces, while more complex designs with sleeves or collars can exceed 10. Buyers should balance design complexity with manufacturing capacity and cost constraints, especially when scaling production for diverse international markets.

5. Adjustment and Customization Options

Patterns that allow modifications — such as length adjustments, sleeve variations, or neckline changes — provide flexibility for regional fashion trends and customer preferences. This adaptability is valuable for B2B buyers aiming to offer tailored collections without investing in entirely new designs.

6. Digital Format and Precision

Many suppliers offer digital pattern files (e.g., PDF, DXF) compatible with CAD software and automated cutting machines. High-precision digital patterns reduce errors and waste, streamlining production. International buyers should confirm file formats and compatibility with their manufacturing technology.

Common Trade Terminology for Wrap Dress Pattern Procurement

OEM (Original Equipment Manufacturer)

Refers to manufacturers who produce patterns or garments based on a buyer’s design specifications, branding, and quality standards. OEM agreements allow buyers to maintain product uniqueness and control over quality, which is essential when entering competitive markets.

MOQ (Minimum Order Quantity)

The smallest quantity of patterns or garments a supplier is willing to produce in one order. MOQs vary widely; understanding this helps buyers, especially SMEs in emerging markets, plan inventory and cash flow effectively.

RFQ (Request for Quotation)

A formal inquiry sent to suppliers asking for price, lead times, and terms based on specific requirements. Accurate RFQs that include detailed technical specs and quantities expedite the sourcing process and help secure competitive offers.

Incoterms (International Commercial Terms)

Standardized trade terms defining responsibilities for shipping, insurance, and customs between buyer and seller (e.g., FOB, CIF, DDP). Knowing Incoterms ensures clarity in logistics and cost allocation, which is critical for cross-border transactions involving regions like the Middle East or South America.

Tech Pack

A comprehensive document containing all technical details about the wrap dress pattern, including measurements, materials, construction instructions, and quality standards. Providing a detailed tech pack minimizes misunderstandings and ensures consistent product quality.

Lead Time

The time required from order placement to delivery. For B2B buyers, especially those managing seasonal fashion cycles, understanding lead times helps coordinate production schedules and market launches efficiently.

By mastering these technical properties and trade terms, international B2B buyers can optimize their sourcing strategies for wrap dress patterns. This leads to better product quality, cost control, and successful market entry across diverse regions such as Africa, South America, the Middle East, and Europe.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the wrap dress pattern Sector

Market Overview & Key Trends

The global wrap dress pattern market is shaped by increasing demand for versatile, customizable fashion solutions that cater to diverse body types and cultural preferences. International B2B buyers, especially from regions such as Africa, South America, the Middle East, and Europe, are leveraging wrap dress patterns as a gateway to tap into expanding local and export markets. Countries like Egypt and Mexico are emerging as key players due to their growing textile industries and skilled garment manufacturing workforce.

Key Market Drivers:

- Customization and Versatility: Wrap dress patterns offer adjustable fits and styles, appealing to a broad demographic and enabling manufacturers to create differentiated product lines.

- Digital Pattern Access: The rise of digital pattern distribution platforms facilitates rapid sourcing and sampling, reducing lead times and enabling agile production cycles.

- Regional Fashion Adaptation: Buyers increasingly seek patterns that can be adapted to local tastes and climates, such as lightweight fabrics for hot climates or modest sleeve styles preferred in Middle Eastern markets.

Emerging B2B Trends:

- Integration of Technology: 3D virtual prototyping and AI-driven fit analysis are enhancing pattern precision and reducing physical sample costs.

- Collaborative Sourcing Models: Buyers are forming strategic partnerships with pattern designers and fabric suppliers to co-develop exclusive designs and ensure supply chain resilience.

- Focus on Small-Batch Production: To respond to fast-changing fashion trends and reduce inventory risks, small-batch and made-to-order sourcing models are gaining traction.

For international buyers, understanding these dynamics is essential for selecting suppliers who offer not only high-quality wrap dress patterns but also agility in customization and responsiveness to market shifts.

Sustainability & Ethical Sourcing in B2B

Sustainability has become a critical factor in the wrap dress pattern sector, driven by both regulatory pressures and consumer demand for environmentally responsible fashion. The environmental footprint of textile production—water usage, chemical treatments, and waste—directly impacts sourcing decisions.

Environmental Impact Considerations:

- Eco-Friendly Materials: Organic cotton, Tencel, and recycled polyester fabrics are increasingly preferred in wrap dress manufacturing to reduce carbon emissions and water consumption.

- Waste Reduction: Pattern efficiency and zero-waste design techniques help minimize fabric offcuts, aligning with circular economy principles.

- Chemical Safety: Compliance with restricted substance lists (RSLs) and certifications such as OEKO-TEX® ensures that dyes and finishes used in fabrics are non-toxic and safe.

Ethical Supply Chain Importance:

- WRAP Certification: Buyers prioritizing ethical sourcing often require suppliers to hold Worldwide Responsible Accredited Production (WRAP) certification, which guarantees adherence to labor rights, fair wages, and safe working conditions.

- Transparency and Traceability: Technologies like blockchain are increasingly employed to provide end-to-end supply chain visibility, reinforcing accountability and consumer trust.

- Local Empowerment: Supporting manufacturers in developing regions encourages economic growth and social development, aligning procurement with corporate social responsibility (CSR) goals.

For B2B buyers, integrating sustainability criteria into supplier evaluation not only mitigates risks but also enhances brand reputation and market access in environmentally conscious regions like Europe.

Brief Evolution and Historical Context

The wrap dress pattern traces its roots back to the 1970s when designer Diane von Fürstenberg popularized the wrap dress as a symbol of female empowerment and versatility. Its timeless silhouette—characterized by a front closure that wraps around the body and ties at the waist—has since evolved into a staple in global fashion.

From a B2B perspective, the wrap dress pattern has transitioned from a niche garment template to a scalable product offering adaptable across cultures and markets. Its enduring popularity has encouraged innovation in pattern design, including modular elements and adjustable sizing, enabling manufacturers to meet the growing demand for inclusive and customizable apparel.

Understanding this evolution helps buyers appreciate the pattern’s commercial potential and its role in bridging traditional craftsmanship with modern production technologies. This historical insight supports strategic sourcing decisions aimed at capitalizing on both heritage appeal and contemporary market trends.

Related Video: International Trade 101 | Economics Explained

Frequently Asked Questions (FAQs) for B2B Buyers of wrap dress pattern

-

How can I effectively vet suppliers of wrap dress patterns to ensure quality and reliability?

Begin by requesting samples of the wrap dress patterns to assess design accuracy and clarity of instructions. Verify the supplier’s certifications related to ethical sourcing and manufacturing standards, such as WRAP or ISO certifications, to ensure compliance with labor and quality norms. Check references or reviews from other international buyers, especially those in your region. Additionally, consider a factory audit or third-party inspection to evaluate production capabilities and quality control processes before committing to large orders. -

Is it possible to customize wrap dress patterns to suit specific market needs or branding requirements?

Yes, many suppliers offer customization services including adjustments to dress length, sleeve style, neckline, and fabric recommendations. Customization can also extend to branded labels and packaging tailored for your target market. When negotiating, clearly communicate your design specifications and request detailed tech packs or prototypes. Ensure the supplier can accommodate modifications without significantly increasing lead times or costs, which is crucial for maintaining competitive pricing in diverse international markets. -

What are typical minimum order quantities (MOQs) and lead times when ordering wrap dress patterns from international suppliers?

MOQs for wrap dress patterns vary widely but typically start from 100 to 500 units depending on the complexity and customization level. Lead times generally range from 3 to 8 weeks, factoring in design finalization, sample approval, production, and shipping. Buyers should negotiate clear timelines and confirm supplier capacity to meet urgent or seasonal demands. For markets in Africa, South America, the Middle East, and Europe, consider additional buffer time for customs clearance and local logistics. -

What payment terms are common in international B2B transactions for wrap dress patterns, and how can buyers protect themselves?

Common payment terms include a 30-50% upfront deposit with balance paid upon shipment or delivery. Letters of credit (LC) or escrow services provide added security for large transactions, reducing risk for both parties. Always use formal contracts specifying payment schedules, quality expectations, and penalties for non-compliance. Employing trade finance options or working with trusted payment platforms can facilitate smoother transactions and build trust with new suppliers.

Illustrative Image (Source: Google Search)

-

How important is quality assurance (QA) and certification when sourcing wrap dress patterns, and which standards should I look for?

QA is critical to ensure patterns are accurate, reproducible, and meet end-user expectations. Certifications like WRAP (Worldwide Responsible Accredited Production) demonstrate ethical production practices, which are increasingly demanded in global markets. Additionally, ISO 9001 certification indicates robust quality management systems. Insist on in-line inspections during production and final product audits. This minimizes defects, reduces returns, and protects your brand reputation internationally. -

What logistics considerations should B2B buyers keep in mind when importing wrap dress patterns?

Understand the shipping methods available—air freight for speed, sea freight for cost efficiency—and choose based on urgency and budget. Factor in customs duties, import taxes, and compliance with local regulations in your country, such as Egypt or Mexico. Partnering with experienced freight forwarders familiar with textile and fashion goods helps streamline customs clearance. Also, ensure packaging protects patterns from moisture or damage during transit, preserving quality upon arrival. -

How should disputes or quality issues be handled with international suppliers of wrap dress patterns?

Establish clear dispute resolution clauses in your contract, specifying mediation or arbitration venues. Document all communications and retain samples for evidence. If quality issues arise, request corrective action plans and timelines from the supplier. Maintain open dialogue to negotiate refunds, replacements, or discounts. Using third-party inspection services before shipment can reduce disputes by verifying quality upfront. Strong supplier relationships and proactive communication are key to resolving issues amicably. -

Are there specific considerations when sourcing wrap dress patterns for markets in Africa, South America, the Middle East, and Europe?

Yes, regional preferences in style, sizing, and fabric choice vary significantly. Research local consumer trends to ensure patterns align with market demands. Consider climate differences when selecting fabric recommendations—lightweight for tropical regions, heavier for colder climates. Regulatory compliance, including labeling and safety standards, also differs; ensure suppliers provide documentation that meets each market’s requirements. Lastly, build flexibility into supply chains to adapt to local holidays, import restrictions, or economic fluctuations common in these regions.

Strategic Sourcing Conclusion and Outlook for wrap dress pattern

Strategic sourcing of wrap dress patterns presents a valuable opportunity for international B2B buyers to optimize product offerings while meeting evolving market demands. Key considerations include selecting suppliers that provide versatile, customizable patterns adaptable to diverse consumer preferences across regions such as Africa, South America, the Middle East, and Europe. Emphasizing ethical sourcing and compliance with certifications like WRAP ensures sustainability and brand integrity, which are increasingly decisive factors for global buyers and end customers alike.

Illustrative Image (Source: Google Search)

By leveraging a strategic approach—balancing cost efficiency, quality assurance, and supplier reliability—businesses can secure wrap dress patterns that not only enhance their product portfolio but also foster innovation through design flexibility. This is particularly relevant for markets with varied climate and cultural influences, where adaptable wrap dress styles can drive higher engagement and sales.

Illustrative Image (Source: Google Search)

Looking ahead, international buyers should prioritize partnerships with suppliers who demonstrate agility and commitment to continuous improvement in sourcing practices. Investing in robust supplier evaluation and certification will position businesses to capitalize on emerging trends and consumer expectations. Now is the time to act strategically, sourcing wrap dress patterns that combine style, sustainability, and scalability to gain a competitive edge in the global apparel market.