Your Ultimate Guide to Sourcing Dad And Son Matching Dress

Guide to Dad And Son Matching Dress

- Introduction: Navigating the Global Market for dad and son matching dress

- Understanding dad and son matching dress Types and Variations

- Key Industrial Applications of dad and son matching dress

- Strategic Material Selection Guide for dad and son matching dress

- In-depth Look: Manufacturing Processes and Quality Assurance for dad and son matching dress

- Comprehensive Cost and Pricing Analysis for dad and son matching dress Sourcing

- Spotlight on Potential dad and son matching dress Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for dad and son matching dress

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the dad and son matching dress Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of dad and son matching dress

- Strategic Sourcing Conclusion and Outlook for dad and son matching dress

Introduction: Navigating the Global Market for dad and son matching dress

The global demand for dad and son matching dresses is rapidly growing, fueled by evolving family fashion trends and a rising appreciation for coordinated apparel that celebrates bonding and style. For international B2B buyers, particularly those operating within Africa, South America, the Middle East, and Europe, this niche presents a lucrative opportunity to tap into diverse markets with unique cultural preferences and consumer behaviors. Understanding the nuances of this segment is essential to sourcing products that not only meet quality and style expectations but also resonate deeply with end consumers.

This guide offers a comprehensive roadmap tailored to empower buyers with actionable insights across every stage of the sourcing journey. It covers the diverse types and styles of dad and son matching dresses, highlighting popular materials suited for different climates and cultural tastes. You will gain clarity on manufacturing processes and quality control standards that ensure consistency and durability, vital for maintaining brand reputation in competitive markets. Additionally, the guide evaluates trusted suppliers and cost considerations, enabling strategic decision-making that balances quality with profitability.

By integrating market analysis and frequently asked questions, this resource equips buyers with the knowledge to navigate complex international trade environments confidently. Whether you are sourcing for boutique retail in Italy, mass distribution in Egypt, or emerging markets in South America and Africa, this guide is designed to streamline your procurement process and maximize return on investment. Embrace this opportunity to strengthen your supply chain and deliver compelling, coordinated apparel that appeals to modern families worldwide.

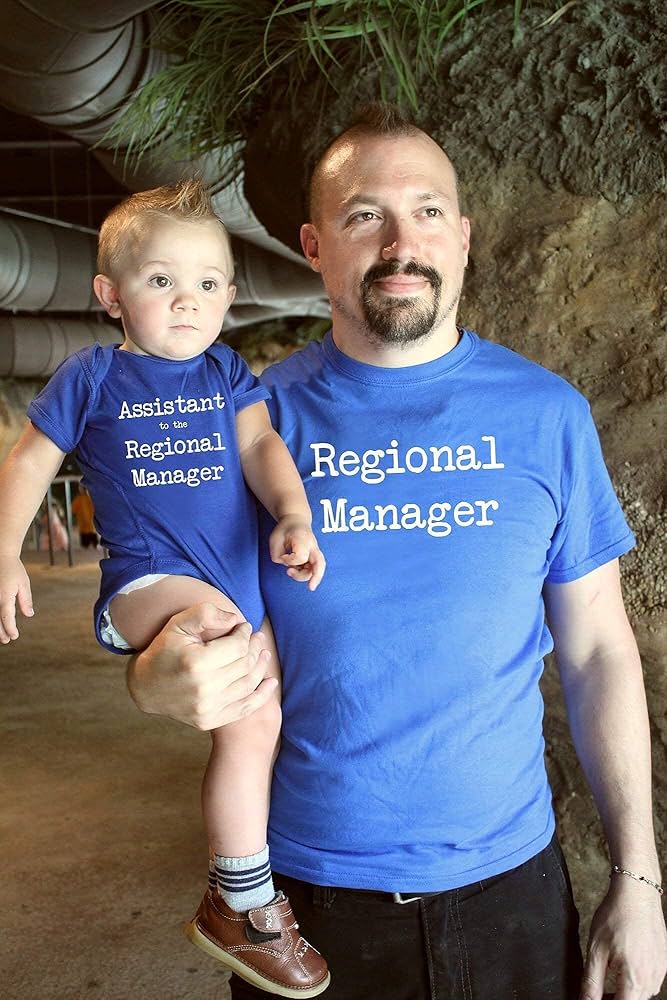

Illustrative Image (Source: Google Search)

Understanding dad and son matching dress Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Traditional Cultural Sets | Matching attire reflecting regional or ethnic styles | Ethnic boutiques, cultural events, family-oriented retail | Pros: High cultural appeal, niche market; Cons: Sizing complexity, fabric sourcing challenges |

| Casual Everyday Wear | Comfortable fabrics, simple coordinated designs | Department stores, casual wear brands | Pros: Broad market, easy to produce; Cons: Lower price margins, high competition |

| Formal Matching Outfits | Coordinated suits, dress shirts, ties, and accessories | Formal wear retailers, event planners | Pros: Premium pricing potential, event-driven sales; Cons: Complex tailoring, inventory risk |

| Seasonal & Thematic Sets | Designs tied to holidays, seasons, or popular themes | Specialty stores, online seasonal campaigns | Pros: High demand spikes, marketing opportunities; Cons: Seasonal demand, trend dependency |

| Sports & Activewear Sets | Matching sports jerseys, tracksuits, or casual athletic wear | Sports retailers, promotional merchandise suppliers | Pros: Growing activewear market, brand collaboration; Cons: Technical fabric sourcing, sizing challenges |

Traditional Cultural Sets

These sets emphasize ethnic or cultural heritage, often using traditional fabrics, patterns, and cuts that resonate with specific regions such as West Africa, the Middle East, or Europe. For B2B buyers, sourcing authentic materials and ensuring accurate sizing for both adults and children is critical. These products cater well to cultural festivals, weddings, and heritage celebrations, offering unique differentiation but requiring specialized suppliers and attention to detail in craftsmanship.

Casual Everyday Wear

This type includes coordinated t-shirts, polos, or casual shirts and pants made from comfortable, easy-care fabrics like cotton blends. It appeals to mass-market retailers targeting families looking for affordable, stylish matching options. B2B buyers benefit from economies of scale and simpler production processes but must navigate intense competition and focus on trend responsiveness to maintain margins.

Formal Matching Outfits

Matching formalwear involves suits, dress shirts, waistcoats, and accessories designed for occasions such as weddings, religious ceremonies, or formal family portraits. These sets demand higher craftsmanship and precise tailoring, often involving premium fabrics. Buyers should consider lead times, customization options, and inventory flexibility due to the event-driven nature of demand, which can offer high returns but also higher risk.

Seasonal & Thematic Sets

These designs revolve around specific holidays (e.g., Christmas, Eid), seasons, or trending themes (cartoons, popular culture). They are ideal for specialty retailers and e-commerce businesses leveraging seasonal marketing campaigns. B2B buyers must manage inventory cycles carefully to avoid overstock and ensure timely delivery aligned with seasonal peaks, balancing creativity with production efficiency.

Sports & Activewear Sets

Matching dad and son sportswear includes jerseys, tracksuits, and other athletic apparel, often featuring team logos or custom prints. This category taps into the growing active lifestyle market and brand collaborations. Buyers should prioritize sourcing technical fabrics with moisture-wicking properties and consider flexible sizing options. Challenges include managing fabric costs and ensuring durability while maintaining appealing designs.

Related Video: Large Language Models (LLMs) – Everything You NEED To Know

Key Industrial Applications of dad and son matching dress

| Industry/Sector | Specific Application of dad and son matching dress | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail & E-commerce | Seasonal and festive promotional collections | Drives family-oriented sales, enhances brand loyalty | Quality fabric, trend alignment, scalable production, cultural relevance |

| Event & Celebration Planning | Coordinated outfits for family events and photoshoots | Creates unique selling points, increases event package value | Customization options, timely delivery, size inclusivity |

| Hospitality & Tourism | Uniforms or themed apparel for family-oriented resorts | Enhances guest experience, promotes family engagement | Durable materials, comfort, easy maintenance |

| Fashion & Apparel Manufacturing | Capsule collections featuring matching family attire | Expands product lines, taps into niche markets | Fabric sourcing, design flexibility, compliance with regional regulations |

| Wholesale Distributors | Bulk supply to boutiques and specialty stores | Economies of scale, broad market reach | Competitive pricing, reliable supply chain, quality consistency |

Dad and son matching dresses have carved a niche across several industries by fulfilling unique family-centric needs. In Retail & E-commerce, these matching outfits are leveraged during seasonal or festive periods to attract family buyers seeking coordinated looks. For international B2B buyers in regions like Africa and South America, ensuring the fabric quality meets climate demands (e.g., breathable cotton for hot climates) and aligning designs with local cultural preferences is critical for success.

Within Event & Celebration Planning, matching dresses are often used for family photoshoots, weddings, or religious ceremonies, where coordinated attire adds emotional and aesthetic value. Buyers, especially from the Middle East and Europe, prioritize customization capabilities and size inclusivity to cater to diverse family compositions, ensuring timely delivery to meet event deadlines.

The Hospitality & Tourism sector benefits by offering dad and son matching dresses as part of themed resort uniforms or family activity apparel. This application enhances guest experience and promotes family bonding. For buyers sourcing from regions like Egypt or Italy, durability and comfort are paramount, as garments must withstand frequent use and diverse weather conditions while maintaining a stylish appeal.

Illustrative Image (Source: Google Search)

In Fashion & Apparel Manufacturing, incorporating matching family attire into capsule collections allows brands to tap niche markets focused on family lifestyle apparel. B2B buyers should focus on sourcing flexible fabrics and ensuring compliance with regional textile regulations, particularly when targeting European markets with strict quality standards.

Finally, Wholesale Distributors play a crucial role in supplying these garments in bulk to specialty boutiques and stores targeting family buyers. For distributors operating across continents, competitive pricing, consistent quality, and a reliable supply chain are essential to maintain market competitiveness and satisfy demand fluctuations.

By understanding these industrial applications and their specific requirements, international B2B buyers can strategically source dad and son matching dresses that resonate with their target markets, optimize operational efficiency, and boost commercial success.

Related Video: LABORATORY APPARATUS AND THEIR USES

Strategic Material Selection Guide for dad and son matching dress

Cotton Fabric

Key Properties:

Cotton is a natural fiber known for its breathability, softness, and moisture absorption. It performs well in warm climates due to its excellent ventilation properties and is hypoallergenic, making it suitable for sensitive skin.

Pros & Cons:

Cotton offers high comfort and durability with good color retention after multiple washes. It is relatively easy to manufacture and widely available, which helps keep costs moderate. However, cotton wrinkles easily and can shrink if not pre-treated. It also requires more water and pesticides during cultivation, which may concern sustainability-focused buyers.

Impact on Application:

Ideal for casual and semi-formal dad and son matching dresses, especially in regions with hot climates like parts of Africa and the Middle East. Cotton’s breathability ensures comfort for children and adults alike. However, it may not be the best choice for formal or heavily structured garments due to its tendency to wrinkle.

B2B Considerations:

Buyers in Europe (e.g., Italy) often prioritize organic or sustainably sourced cotton compliant with GOTS (Global Organic Textile Standard). In South America and Africa, local sourcing options may reduce lead times and costs but require verification of quality standards such as ASTM or ISO certifications. Cotton blends may be preferred for enhanced durability and wrinkle resistance.

Polyester Fabric

Key Properties:

Polyester is a synthetic fiber known for its strength, wrinkle resistance, and quick-drying properties. It maintains shape well and is resistant to shrinking and stretching.

Pros & Cons:

Polyester is cost-effective and highly durable, making it suitable for high-volume production. It is easy to care for and resists stains and mildew. However, it is less breathable than natural fibers, which can reduce comfort in hot climates. Polyester may also retain odors and is less eco-friendly due to its petroleum-based origin.

Impact on Application:

Polyester is ideal for dad and son matching dresses intended for frequent use or travel, especially in cooler or temperate climates such as Europe. Its wrinkle resistance makes it attractive for buyers targeting convenience and longevity. Blending polyester with cotton can improve comfort while retaining durability.

B2B Considerations:

International buyers should consider compliance with OEKO-TEX Standard 100 to ensure the absence of harmful substances. Middle Eastern markets often demand fabrics that withstand high temperatures without degrading, making polyester blends popular. South American buyers may focus on cost-efficiency and ease of maintenance.

Linen Fabric

Key Properties:

Linen, derived from flax fibers, is prized for its natural luster, breathability, and moisture-wicking ability. It performs excellently in hot and humid environments.

Pros & Cons:

Linen is highly durable and becomes softer with each wash. It is biodegradable and eco-friendly, appealing to sustainability-conscious buyers. However, linen wrinkles very easily and can be more expensive than cotton or polyester. Its production is also more labor-intensive.

Impact on Application:

Linen is well-suited for premium dad and son matching dresses in warm climates such as North Africa and the Mediterranean region. Its texture and breathability provide comfort and a sophisticated look. Due to its wrinkling tendency, it is less suited for formal wear requiring a crisp appearance.

B2B Considerations:

Buyers from Italy and Egypt often seek high-quality linen with certifications like OEKO-TEX and compliance with European REACH regulations. African buyers may value locally sourced linen for cultural resonance and cost advantages. Education on care instructions is important to reduce returns due to wrinkling.

Viscose (Rayon) Fabric

Key Properties:

Viscose is a semi-synthetic fiber made from regenerated cellulose. It offers a silky feel, good drape, and breathability, combining aspects of natural and synthetic fibers.

Pros & Cons:

Viscose is affordable and versatile, with excellent dye absorption for vibrant colors. It is softer than cotton and more breathable than polyester. However, viscose can wrinkle easily and may weaken when wet, requiring careful handling during manufacturing. It is less durable than cotton or polyester.

Impact on Application:

Viscose is suitable for stylish dad and son matching dresses that emphasize softness and color vibrancy, popular in fashion-conscious European and South American markets. Its drape makes it ideal for casual and semi-formal styles but less ideal for rugged or high-wear use.

B2B Considerations:

Buyers should verify viscose sourcing and production methods to ensure compliance with environmental standards, especially in Europe where regulations are stringent. Middle Eastern buyers may prefer blends with polyester to enhance durability. Proper quality control during manufacturing is critical to avoid shrinkage and deformation.

| Material | Typical Use Case for dad and son matching dress | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Cotton | Casual and semi-formal matching dresses, warm climates | Breathable, comfortable, hypoallergenic | Wrinkles easily, may shrink, water-intensive cultivation | Medium |

| Polyester | Durable, travel-friendly matching dresses, temperate climates | Wrinkle-resistant, durable, cost-effective | Less breathable, retains odors, less eco-friendly | Low |

| Linen | Premium matching dresses for hot/humid regions | Highly breathable, eco-friendly, durable | Wrinkles easily, higher cost, labor-intensive production | High |

| Viscose (Rayon) | Fashion-forward casual/semi-formal matching dresses | Soft feel, excellent drape, vibrant colors | Less durable, wrinkles, weak when wet | Medium |

In-depth Look: Manufacturing Processes and Quality Assurance for dad and son matching dress

Overview of Manufacturing Processes for Dad and Son Matching Dresses

Producing high-quality dad and son matching dresses involves a carefully coordinated manufacturing workflow designed to ensure consistency, comfort, and style across sizes and designs. For international B2B buyers, understanding these stages helps in selecting reliable suppliers and ensuring your orders meet market expectations.

1. Material Preparation

Material preparation is the foundation of quality garment manufacturing. It begins with sourcing the right fabrics—commonly cotton blends, linen, or polyester mixes—chosen for durability, comfort, and ease of maintenance. For matching outfits, fabric consistency across different sizes is crucial.

Illustrative Image (Source: Google Search)

- Fabric Inspection: Incoming fabric rolls undergo visual and mechanical inspection for defects such as color variation, weaving faults, or contamination.

- Pre-treatment: Processes like washing, dyeing, or heat-setting stabilize the fabric to prevent shrinkage and maintain color fastness.

- Cutting Preparation: Fabric is layered uniformly and aligned according to the grain to optimize yield and maintain garment shape.

2. Forming (Cutting and Pattern Making)

The forming stage translates design concepts into physical garment pieces.

- Pattern Making: Based on the dad and son matching dress design, technical patterns are created for each size. Precision here is vital to maintain proportional matching between adult and child versions.

- Cutting: Using automated cutting machines or manual cutting tables, fabric layers are cut according to the patterns. Advanced manufacturers use computer-aided design (CAD) systems for accuracy and fabric utilization efficiency.

- Marker Making: This step involves arranging pattern pieces on fabric layers to minimize waste, a key cost factor for B2B buyers focusing on sustainability and price competitiveness.

3. Assembly (Sewing and Construction)

Assembly is where the cut pieces are stitched into finished garments.

- Sewing Operations: Skilled operators or automated sewing machines assemble the dresses. For matching sets, uniform stitch types and seam finishes ensure both pieces have a consistent look and durability.

- Specialized Techniques: Features like reinforced seams on shoulders, double stitching, or flatlock seams may be employed to enhance strength, especially for children’s wear.

- Attachment of Components: Elements such as buttons, zippers, labels, and decorative trims are added during assembly. Consistency in hardware between dad and son pieces reinforces the matching concept.

4. Finishing

The finishing stage polishes the garment to retail-ready condition.

- Pressing and Ironing: Garments are steamed and pressed to remove creases and maintain a crisp appearance.

- Quality Trims: Removal of loose threads, alignment of labels, and verification of buttonholes or fasteners.

- Packaging: Each matching dress set is carefully folded and packed, often with tags or hangers that identify them as a coordinated pair, ready for shipment.

Quality Assurance (QA) and Quality Control (QC) Frameworks

Ensuring consistent quality in dad and son matching dresses requires rigorous QC protocols aligned with international standards and tailored to the global B2B market.

Relevant International and Industry Standards

- ISO 9001: The most widely recognized international quality management standard, focusing on process consistency, customer satisfaction, and continual improvement.

- OEKO-TEX® Standard 100: Important for textile products, certifying that fabrics are free from harmful substances, a key consideration for children’s garments.

- Global Organic Textile Standard (GOTS): For buyers emphasizing organic or sustainable textiles.

- CE Marking: For apparel sold in Europe, indicating compliance with EU safety, health, and environmental protection requirements.

- Specific Regional Certifications: Some markets, such as the Middle East, may require compliance with local textile and apparel standards; for example, SASO in Saudi Arabia.

QC Checkpoints Throughout Production

- Incoming Quality Control (IQC): Inspection of raw materials (fabric, trims) before production. This includes color matching, weight, hand feel, and defect rate checks.

- In-Process Quality Control (IPQC): Ongoing inspections during cutting, sewing, and assembly. Operators and QC staff monitor seam strength, stitch density, size accuracy, and matching consistency between father and son garments.

- Final Quality Control (FQC): Post-production inspection focusing on overall appearance, dimensional checks, colorfastness, and functional testing (buttons, zippers). This step often includes random sampling and 100% checks for critical orders.

Common Testing Methods

- Dimensional Measurement: Using standardized sizing charts to ensure garments meet specified measurements for both adult and child sizes.

- Colorfastness Tests: Assessing resistance to washing, rubbing, and light exposure to guarantee matching colors do not fade or bleed.

- Tensile and Seam Strength Tests: Mechanical tests to measure the durability of stitches and fabric under stress.

- Chemical Testing: Ensuring fabrics and dyes comply with safety standards, especially important for children’s wear.

- Shrinkage Tests: Washing garments under controlled conditions to check for size stability.

How B2B Buyers Can Verify Supplier Quality Controls

For buyers in Africa, South America, the Middle East, and Europe, verifying supplier QC capabilities is critical to mitigate risks such as inconsistent quality, delayed shipments, or non-compliance with local regulations.

- Factory Audits: Conduct on-site or third-party audits assessing manufacturing processes, worker skill levels, and QC systems. Audits verify compliance with ISO 9001 or other quality management systems.

- Review of QC Reports: Demand detailed QC inspection reports covering IQC, IPQC, and FQC stages. These reports should include defect rates, non-conformance records, and corrective actions.

- Third-Party Inspections: Engage independent inspection agencies (e.g., SGS, Bureau Veritas) to perform pre-shipment inspections, verifying quality and quantity before goods leave the factory.

- Sample Approvals: Request initial production samples for physical evaluation, including fit, fabric, and finishing. Approve samples before mass production begins to reduce rework.

- Supplier Certifications: Validate certifications such as OEKO-TEX®, GOTS, or ISO 9001 through official registries or certification bodies to ensure authenticity.

QC and Certification Nuances for International Buyers

- Regional Market Requirements: European buyers, especially from Italy, often demand strict adherence to EU regulations, including REACH compliance for chemicals in textiles. Buyers in Egypt or the Middle East should verify conformity with local import standards and customs documentation.

- Cultural and Climate Considerations: For African and South American markets, fabric choices and garment durability must accommodate local climates and consumer preferences, influencing quality parameters.

- Sustainability and Ethical Compliance: Increasingly, buyers from all regions prioritize suppliers who demonstrate sustainable sourcing and ethical manufacturing practices. Certifications such as Fair Trade or WRAP may be requested.

- Communication and Documentation: Clear communication of QC expectations, inspection criteria, and documentation standards is essential. Use digital platforms to track quality data in real-time to facilitate transparency and faster issue resolution.

Summary for B2B Buyers

Understanding the detailed manufacturing stages and robust quality assurance systems for dad and son matching dresses empowers B2B buyers to make informed sourcing decisions. Prioritizing suppliers with:

- Transparent and efficient production workflows,

- Compliance with international and regional quality standards,

- Comprehensive QC checkpoints and testing,

- Verified certifications and audit reports,

will help mitigate risks and ensure delivery of consistent, safe, and appealing matching dress sets tailored to diverse global markets. This approach is especially valuable for buyers targeting Africa, South America, the Middle East, and Europe, where regulatory landscapes and consumer expectations vary but demand high-quality, reliable apparel products.

Related Video: Amazing Garment Manufacturing Process from Fabric to Finished Product Inside the Factory

Comprehensive Cost and Pricing Analysis for dad and son matching dress Sourcing

When sourcing dad and son matching dresses, understanding the detailed cost structure and pricing dynamics is essential for international B2B buyers aiming to optimize procurement and profitability. This analysis breaks down the key cost components, price influencers, and strategic buyer tips tailored for buyers from Africa, South America, the Middle East, and Europe.

Key Cost Components in Dad and Son Matching Dress Sourcing

-

Materials

Fabric quality and type (e.g., cotton, linen, blends) are the most significant cost drivers. Matching sets require consistent fabric sourcing to ensure uniformity in texture and color, often increasing material costs. Additional components such as buttons, zippers, and embroidery threads also factor in. -

Labor

Labor costs vary substantially by manufacturing region. Countries with skilled yet cost-effective labor pools offer competitive pricing, but for matching sets, precision in stitching and finishing is critical, sometimes requiring higher-skilled workers, which impacts labor expenses. -

Manufacturing Overhead

This includes factory utilities, equipment depreciation, and indirect labor. Efficient factories with streamlined workflows (e.g., progressive bundle or section production systems) reduce overhead per unit, influencing final pricing. -

Tooling and Sampling

Initial setup costs for pattern making, sample production, and customization tooling are amortized over order volumes. Custom patterns for coordinated dad and son designs may increase upfront tooling expenses. -

Quality Control (QC)

Rigorous QC ensures matching sets meet quality standards and design specifications, reducing returns and enhancing brand reputation. QC costs include inspection labor and possible rework. -

Logistics and Shipping

Freight costs depend on shipment mode (sea, air, or land), volume, and destination. Buyers in Africa, South America, the Middle East, and Europe should factor in customs duties, import taxes, and potential delays impacting landed costs. -

Supplier Margin

Manufacturers include a margin to cover profit and risk. This margin can fluctuate based on order size, relationship strength, and market demand.

Influencing Factors on Pricing

-

Order Volume / Minimum Order Quantity (MOQ): Larger orders typically yield lower per-unit costs due to economies of scale. Negotiating MOQs aligned with sales forecasts is crucial to balance inventory and cost.

-

Customization and Design Complexity: Intricate matching patterns, embroidery, or special finishes elevate production complexity and costs. Buyers should evaluate the necessity of such features against budget constraints.

-

Material Quality and Certifications: Sustainable or certified fabrics (e.g., organic cotton, OEKO-TEX) command premium prices but enhance market appeal, especially in environmentally conscious European markets.

-

Supplier Capabilities and Location: Suppliers with advanced technology or proximity to raw materials may offer better pricing or lead times. However, regional labor laws and infrastructure quality also impact costs.

-

Incoterms and Payment Terms: Shipping terms (FOB, CIF, DDP) affect who bears freight and customs costs, influencing total expenditure. Favorable payment terms (e.g., letters of credit, net 30) can improve cash flow management.

Actionable Buyer Tips for International B2B Procurement

-

Negotiate Beyond Unit Price: Engage suppliers on MOQ flexibility, payment terms, and bundled services such as packaging or labeling to reduce overall costs.

-

Assess Total Cost of Ownership (TCO): Include all ancillary costs like freight, duties, warehousing, and quality assurance to avoid surprises in landed cost calculations.

-

Leverage Volume and Long-term Contracts: Buyers from emerging markets such as Egypt or Brazil can negotiate better pricing and priority production slots by committing to multi-season contracts.

-

Understand Local Market Preferences: For example, European buyers may prioritize certifications and sustainable sourcing, while Middle Eastern buyers might value customization and exclusivity, impacting cost priorities.

-

Use Incoterms Strategically: For less experienced importers, opting for DDP (Delivered Duty Paid) can simplify logistics, albeit at a higher cost, while experienced buyers might prefer FOB or EXW to control shipping.

-

Plan for Currency Fluctuations: Especially relevant for buyers in Africa and South America, where exchange rates can vary widely, affecting final purchase costs.

Disclaimer on Pricing

Pricing for dad and son matching dresses varies widely based on the factors outlined above. The figures presented in this analysis are indicative and should be validated through direct supplier quotations and market research. Buyers are encouraged to conduct thorough due diligence and consider both cost and quality to ensure a competitive and sustainable sourcing strategy.

By systematically analyzing these cost components and price influencers, international B2B buyers can make informed sourcing decisions, negotiate effectively, and optimize their procurement of dad and son matching dress collections in diverse global markets.

Spotlight on Potential dad and son matching dress Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘dad and son matching dress’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for dad and son matching dress

Critical Technical Properties for Dad and Son Matching Dress

When sourcing dad and son matching dresses, understanding key technical specifications is essential to ensure product quality, consistency, and customer satisfaction across diverse international markets such as Africa, South America, the Middle East, and Europe.

-

Fabric Composition and Grade

The fabric type (e.g., 100% cotton, cotton-polyester blends) and its grade (premium, mid-range) directly impact comfort, durability, and appearance. High-grade fabrics resist pilling and fading, crucial for matching outfits that often undergo frequent washing. For B2B buyers, specifying fabric grade upfront reduces returns and enhances brand reputation. -

Color Fastness and Dye Quality

Matching dresses require consistent color tones across sizes and batches. Color fastness measures how well the fabric maintains its color after washing and exposure to light. Buyers should request lab test reports or certifications (e.g., ISO 105) to verify color durability, especially when dealing with vibrant or culturally significant colors. -

Size Tolerance and Grading Accuracy

Size tolerance defines the acceptable variation in garment dimensions from the specified measurements. Tight tolerances (±0.5 cm) ensure matching fits between dad and son outfits, a critical factor for customer satisfaction. Accurate grading ensures proportional scaling across sizes, maintaining the visual harmony of matching sets. -

Stitching Quality and Seam Strength

The type of stitching (single needle, double needle) and seam strength (measured in Newtons) affect the garment’s longevity. Reinforced stitching on stress points like shoulders and sleeves is important for active wearers. B2B buyers should request quality standards or conduct random checks to minimize defects. -

Finish and Detailing

Finishing touches such as embroidery, appliqué, or printed logos must be durable and consistent across sets. Additionally, the finishing process (e.g., pre-shrinking, anti-wrinkle treatment) improves the final product’s usability. Clear technical specs for finishes ensure the product meets market expectations. -

Compliance with Safety and Environmental Standards

For international trade, compliance with standards like OEKO-TEX® or REACH is critical, especially in Europe and parts of Africa and the Middle East. These certifications guarantee the absence of harmful substances, aligning with increasing consumer demand for safe and sustainable apparel.

Key Trade Terminology for Dad and Son Matching Dress Procurement

Navigating apparel sourcing requires familiarity with industry jargon and trade terms that facilitate smooth communication and transaction efficiency.

-

OEM (Original Equipment Manufacturer)

OEM refers to manufacturers who produce garments based on the buyer’s designs and specifications. For matching dresses, OEM partnerships allow customization in fabric, cut, and branding, offering buyers flexibility and exclusivity in their product lines. -

MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a manufacturer is willing to produce in one order. Understanding MOQ is vital to balance inventory risk and cost efficiency, especially for buyers entering new markets or testing matching dress concepts. -

RFQ (Request for Quotation)

An RFQ is a formal document buyers send to suppliers requesting detailed price, lead time, and terms for a specified quantity and product specification. Clear and detailed RFQs help suppliers provide accurate offers and reduce negotiation time. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers for shipping, insurance, and customs clearance. Common terms include FOB (Free on Board) and CIF (Cost, Insurance, and Freight). Knowing Incoterms helps buyers from regions like South America and the Middle East manage logistics costs and risks effectively. -

Lead Time

Lead time is the period from order confirmation to delivery. For matching dresses, lead time affects inventory planning and seasonality. Buyers should negotiate realistic lead times considering production complexity and shipping distances. -

Tech Pack

A tech pack is a comprehensive document detailing the product’s design, materials, measurements, and construction instructions. Providing a precise tech pack reduces errors during manufacturing, ensuring that dad and son matching dresses meet quality expectations consistently.

By mastering these technical properties and trade terms, international B2B buyers can optimize their sourcing strategies for dad and son matching dresses, ensuring products that resonate with their target markets while maintaining operational efficiency.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the dad and son matching dress Sector

Market Overview & Key Trends

The dad and son matching dress sector is experiencing dynamic growth fueled by a rising global demand for family-centric fashion that celebrates bonding and shared identity. This niche market is particularly appealing to international B2B buyers targeting regions like Africa, South America, the Middle East, and Europe, where cultural values emphasize family unity and coordinated dressing is gaining popularity for social occasions, holidays, and casual wear.

Key market drivers include increasing disposable incomes, social media influence promoting family fashion trends, and the expansion of e-commerce platforms facilitating direct-to-consumer sales. Buyers from regions such as Italy and Egypt are witnessing heightened interest in customizable and culturally resonant matching outfits that combine traditional aesthetics with contemporary design.

In sourcing, flexibility and speed are crucial. Manufacturers adopting agile production methods like progressive bundle systems and one-piece flow systems can better meet fluctuating demand and customization requests. There is a growing trend toward digital integration in supply chain management, enabling real-time communication between design, production, and logistics teams to reduce errors and shorten lead times.

International buyers benefit from partnering with suppliers who offer a range of fabric options—from lightweight cotton blends suited for warmer climates in Africa and the Middle East, to more structured fabrics favored in European markets. Additionally, multi-channel sourcing strategies that combine local and international fabric procurement help optimize costs and delivery schedules.

Sustainability & Ethical Sourcing in B2B

Sustainability is increasingly central in the dad and son matching dress sector, as buyers and consumers demand transparency and responsibility in supply chains. The environmental impact of textile production—particularly water usage, chemical dyes, and waste—calls for adopting eco-friendly materials such as organic cotton, bamboo blends, and recycled fibers. These materials not only reduce environmental footprint but also appeal to conscious consumers in Europe and South America.

Ethical sourcing extends beyond materials to encompass fair labor practices and safe working conditions. B2B buyers should prioritize suppliers with certifications like Global Organic Textile Standard (GOTS), OEKO-TEX Standard 100, and Fair Trade to ensure compliance with international labor and environmental standards. These certifications provide assurance regarding chemical safety, organic content, and social accountability, which are increasingly non-negotiable in global markets.

Implementing sustainability also involves optimizing manufacturing processes to minimize waste through precise cutting technologies and adopting closed-loop systems for fabric recycling. Buyers can leverage suppliers who integrate sustainability into every stage—from design conceptualization to packaging—to meet regulatory requirements and consumer expectations across diverse markets.

Brief Evolution and Historical Context

The concept of coordinated family dressing dates back centuries, rooted in cultural traditions that signify unity and social status. In recent decades, the dad and son matching dress segment has evolved from informal, handcrafted garments to a structured industry supported by mass production and global trade.

Originally popularized in Western markets, the trend has expanded worldwide, fueled by globalization and digital media showcasing family fashion. Today, it represents a lucrative niche for B2B buyers seeking to capitalize on growing demand for personalized and culturally relevant apparel that strengthens family identity while catering to modern style preferences.

This evolution highlights the importance of understanding regional nuances and consumer behavior to successfully source and market dad and son matching dresses internationally.

Related Video: Specialization and Trade: Crash Course Economics #2

Frequently Asked Questions (FAQs) for B2B Buyers of dad and son matching dress

-

How can I effectively vet suppliers of dad and son matching dresses to ensure quality and reliability?

To vet suppliers, start by requesting detailed company profiles, including years of experience and production capacity. Verify certifications such as ISO, OEKO-TEX, or other relevant textile quality standards. Ask for samples to assess fabric quality, stitching, and design accuracy. Check references or reviews from existing international clients, especially those in your region. Use video calls to inspect factory operations virtually. Prioritize suppliers with transparent communication and who provide clear lead times and after-sales support, reducing risks associated with international transactions. -

What customization options are typically available for dad and son matching dresses, and how should I approach these with manufacturers?

Customization often includes fabric choice, colors, prints, embroidery, sizing adjustments, and packaging design. Discuss your exact requirements early and provide detailed tech packs or design sketches. Confirm if the supplier can handle small batch customizations or if they require higher MOQ for bespoke designs. Request prototypes to validate the customization before mass production. For international buyers, clarify if the supplier can adapt to regional preferences and cultural nuances, which is crucial for markets like the Middle East or Europe. -

What are typical minimum order quantities (MOQs) and lead times for bulk orders of dad and son matching dresses from international suppliers?

MOQs vary widely depending on the supplier’s scale and production capabilities but typically range from 100 to 500 sets per style. Lead times generally span 30 to 60 days, factoring in sampling, production, and quality checks. For buyers from Africa, South America, or the Middle East, consider additional shipping time and customs clearance. Negotiate MOQs based on your market size and request flexible terms if you plan to test new designs. Early communication about timelines helps avoid delays and aligns expectations. -

Which payment methods are safest and most practical for international B2B transactions in apparel sourcing?

Secure payment methods include Letters of Credit (L/C), escrow services, and verified PayPal business accounts. Many suppliers accept wire transfers (T/T), often requiring a 30% deposit upfront and the balance before shipment. For first-time orders, consider using escrow or third-party payment platforms that protect both parties. Avoid full advance payments without verified supplier credibility. Establishing trust with your supplier can lead to more flexible terms like net 30 or net 60 payment cycles. -

What quality assurance (QA) processes should I expect from suppliers of dad and son matching dresses?

Reliable suppliers implement multi-stage QA including fabric inspection, in-line stitching checks, and final product audits. Request documentation of quality control procedures and certifications such as ISO 9001 or BSCI compliance. Insist on pre-shipment inspections either by your own team or a third-party inspection agency. For international buyers, clear defect tolerance thresholds and return policies should be agreed upon in advance. Consistent QA reduces returns and enhances brand reputation in your market. -

Are there specific certifications or standards I should require from suppliers when sourcing dad and son matching dresses for different regional markets?

Yes, certifications depend on target markets. For Europe and some African countries, OEKO-TEX Standard 100 ensures textiles are free from harmful substances. Compliance with REACH regulations is essential for European importers. Middle Eastern markets may require compliance with local textile standards and halal certifications for certain materials. Sustainability certifications like GOTS or Fair Trade can add market appeal globally. Request these certifications upfront to avoid customs issues and enhance product credibility. -

What logistics considerations should I keep in mind when importing dad and son matching dresses from overseas suppliers?

Plan for shipping mode (sea freight is cost-effective for bulk, air freight for urgent orders), customs clearance, and import duties relevant to your country. Work with suppliers who offer FOB (Free on Board) or CIF (Cost, Insurance, and Freight) terms for clarity on responsibilities. Factor in packaging dimensions and weight for accurate freight quotes. For African and South American markets, port congestion and inland transport can cause delays; build buffer time into your schedules. Use experienced freight forwarders familiar with your region. -

How should disputes or quality issues be handled with international suppliers to minimize impact on business?

Establish clear contractual agreements detailing product specifications, inspection rights, and dispute resolution mechanisms before ordering. Use third-party inspection services and document all communications. In case of quality issues, negotiate solutions such as product replacement, discounts, or refunds swiftly to maintain relationships. Employ mediation or arbitration clauses to resolve conflicts amicably without costly litigation. Maintaining professional, transparent dialogue encourages cooperation and preserves long-term supplier partnerships.

Strategic Sourcing Conclusion and Outlook for dad and son matching dress

Strategic sourcing in the dad and son matching dress market offers international B2B buyers a unique opportunity to capitalize on growing consumer demand for coordinated family apparel. By prioritizing reliable suppliers with proven expertise in fabric quality, design innovation, and efficient production workflows, buyers can ensure product consistency and timely delivery. This approach is especially crucial for markets in Africa, South America, the Middle East, and Europe, where cultural preferences and sizing standards may vary significantly.

Key takeaways for buyers include the importance of thorough supplier vetting, engaging in sample approvals to validate design and fit, and leveraging manufacturers that offer flexible production systems such as section production or progressive bundle methods to optimize cost and speed. Embracing sustainable sourcing options can further differentiate product offerings in competitive markets like Italy and Egypt, where consumer awareness around ethical fashion is increasing.

Looking ahead, the dad and son matching dress segment is poised for expansion driven by social media trends and rising family-oriented lifestyles globally. International buyers who adopt a strategic sourcing mindset—balancing quality, innovation, and cultural relevance—will position themselves to capture emerging opportunities and build lasting partnerships with manufacturers. Now is the time to engage with trusted apparel vendors and initiate collaborative sourcing strategies that align with evolving market dynamics.