Master Sourcing Wedding Dress Rehearsal Dresses for Global

Guide to Wedding Dress Rehearsal Dresses

- Introduction: Navigating the Global Market for wedding dress rehearsal dresses

- Understanding wedding dress rehearsal dresses Types and Variations

- Key Industrial Applications of wedding dress rehearsal dresses

- Strategic Material Selection Guide for wedding dress rehearsal dresses

- In-depth Look: Manufacturing Processes and Quality Assurance for wedding dress rehearsal dresses

- Comprehensive Cost and Pricing Analysis for wedding dress rehearsal dresses Sourcing

- Spotlight on Potential wedding dress rehearsal dresses Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for wedding dress rehearsal dresses

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the wedding dress rehearsal dresses Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of wedding dress rehearsal dresses

- Strategic Sourcing Conclusion and Outlook for wedding dress rehearsal dresses

Introduction: Navigating the Global Market for wedding dress rehearsal dresses

The wedding dress rehearsal dress occupies a pivotal role in the bridal journey, serving not only as a stylish precursor to the wedding day but also as a functional garment that ensures comfort and confidence during pre-wedding events. For B2B buyers operating across diverse regions such as Africa, South America, the Middle East, and Europe, sourcing these dresses requires a nuanced understanding of global market dynamics, cultural preferences, and quality standards.

This guide delivers a comprehensive roadmap tailored specifically for international wholesalers, retailers, and distributors aiming to excel in the wedding dress rehearsal niche. It covers an extensive range of critical topics, including the variety of dress types—ranging from elegant cocktail styles to casual chic options—and the selection of premium materials that balance aesthetics with durability. Insightful analysis of manufacturing processes and quality control measures empowers buyers to identify reliable suppliers who consistently meet international standards.

Additionally, the guide provides an in-depth examination of pricing structures, supply chain considerations, and emerging market trends that influence buying decisions across regions like Brazil and Poland. Practical FAQs address common challenges, such as navigating import regulations and adapting inventory to local tastes, enabling buyers to mitigate risks and maximize profitability.

By synthesizing these elements, this resource equips international B2B buyers with actionable intelligence and strategic insights to make informed sourcing decisions. Whether expanding an existing bridal collection or launching a new product line, buyers will gain the expertise needed to capitalize on the growing demand for wedding dress rehearsal dresses worldwide.

Understanding wedding dress rehearsal dresses Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Casual Chic Dresses | Lightweight fabrics, simple silhouettes, often midi length | Rehearsal dinners, informal bridal events | Pros: Versatile, cost-effective; Cons: May lack formality for some markets |

| Elegant Evening Gowns | Luxurious fabrics like satin or chiffon, floor-length | Formal rehearsal dinners, upscale bridal boutiques | Pros: High perceived value, premium appeal; Cons: Higher cost, inventory risk |

| Convertible/Reversible Dresses | Multi-style wearability, adjustable design elements | Boutiques targeting multi-use dresses, rental services | Pros: Added value, flexible styling; Cons: Complex sizing, higher production cost |

| Cultural/Traditional Variations | Incorporates regional motifs, fabrics, and cuts | Ethnic bridal boutiques, culturally specific markets | Pros: Niche market appeal, differentiation; Cons: Limited crossover appeal, requires cultural expertise |

| Minimalist Modern Dresses | Clean lines, neutral tones, minimal embellishments | Contemporary bridal shops, urban markets | Pros: Trend-forward, easy to stock; Cons: May not appeal to traditional buyers |

Casual Chic Dresses

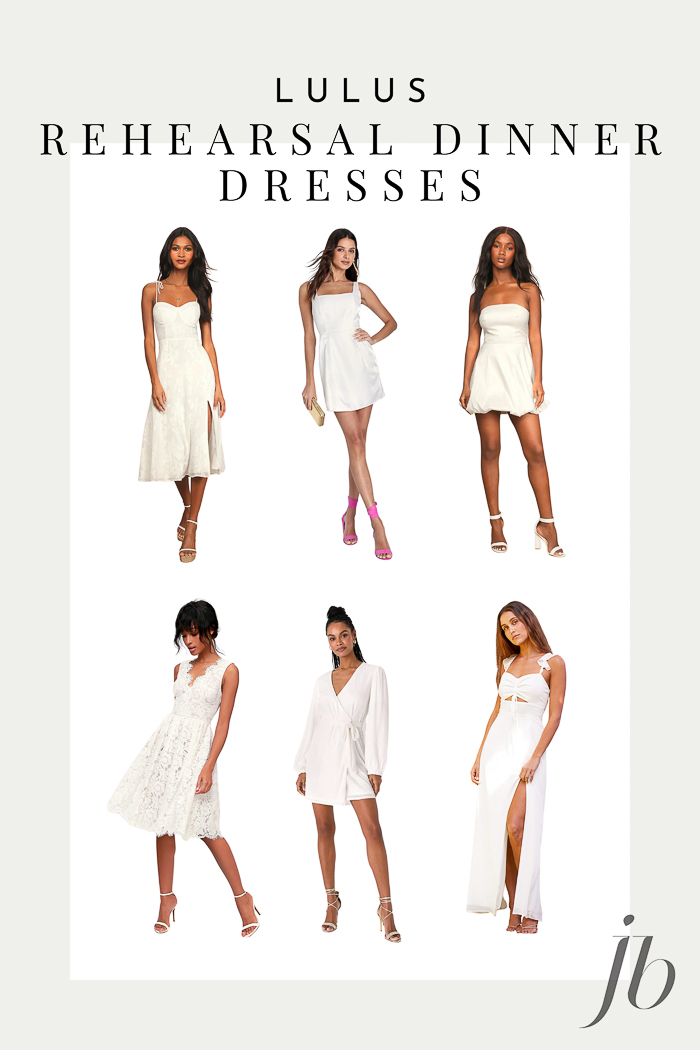

These dresses typically feature breathable, lightweight fabrics such as cotton blends or soft chiffon, with simple, flattering cuts often in midi or tea lengths. They are ideal for rehearsal dinners and informal bridal events, appealing to brides seeking comfort without sacrificing style. For B2B buyers, these dresses offer versatility and affordability, making them suitable for boutiques in emerging markets or regions where less formal celebrations are customary. Buyers should consider fabric sourcing and local climate suitability to optimize inventory turnover.

Elegant Evening Gowns

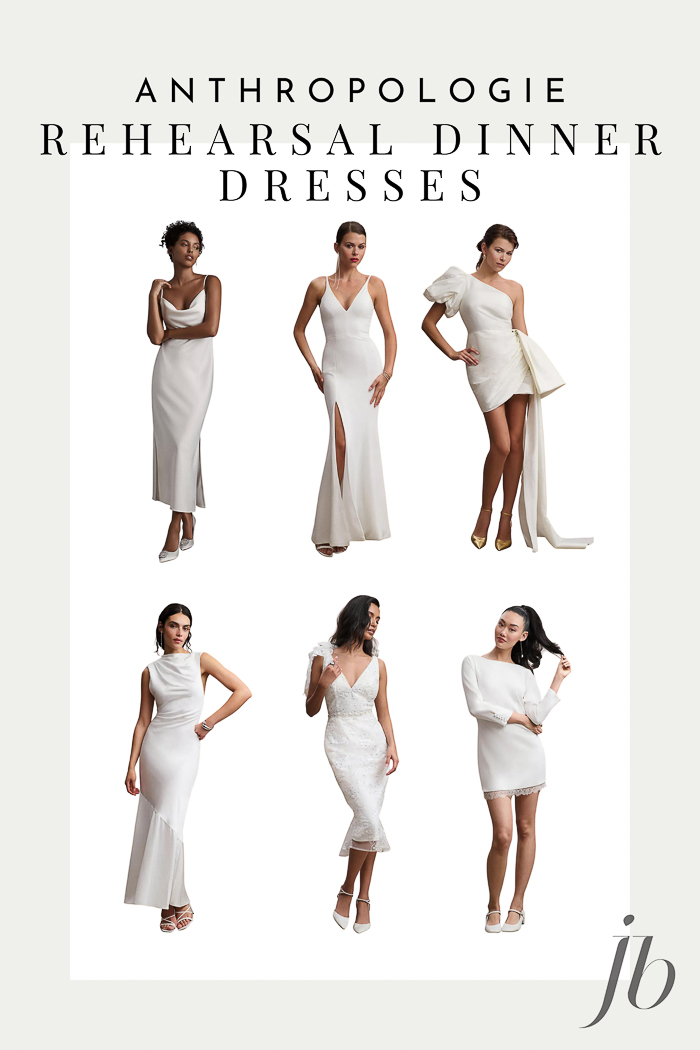

Characterized by premium fabrics like satin, silk, or chiffon, and often floor-length with intricate detailing, these gowns cater to upscale rehearsal dinners and luxury bridal boutiques. They command higher price points and appeal to affluent clientele, especially in European and Middle Eastern markets where formal dress codes prevail. B2B buyers must evaluate supplier reliability for quality consistency and consider inventory risks due to seasonal demand fluctuations. Strategic marketing to luxury segments enhances sales potential.

Convertible/Reversible Dresses

This innovative category features dresses designed for multiple styling options—such as detachable sleeves or reversible colors—offering brides flexibility for different events. These dresses are attractive for boutiques focusing on value and rental services, particularly in urban centers and regions with trend-conscious consumers like Brazil and Poland. Buyers face challenges in complex sizing and higher production costs but benefit from differentiated product offerings that can command premium pricing and reduce return rates.

Cultural/Traditional Variations

Incorporating indigenous fabrics, embroidery, and cuts, these dresses cater to ethnic bridal boutiques and culturally specific markets across Africa, the Middle East, and parts of South America. They provide a unique selling proposition for buyers aiming to serve niche clientele with authentic, heritage-inspired designs. However, success demands cultural expertise and strong supplier relationships to ensure authenticity and quality. While crossover appeal may be limited, these variations can command loyalty and premium pricing within target communities.

Minimalist Modern Dresses

Defined by clean lines, neutral palettes, and minimal embellishments, minimalist dresses appeal to contemporary brides who favor understated elegance. They are well-suited for urban markets and boutiques targeting younger demographics across Europe and South America. For B2B buyers, these dresses are easier to stock due to their timeless appeal and lower risk of rapid style obsolescence. However, buyers should remain aware of regional preferences for more ornate styles to maintain a balanced inventory mix.

Related Video: Large Language Models (LLMs) – Everything You NEED To Know

Key Industrial Applications of wedding dress rehearsal dresses

| Industry/Sector | Specific Application of Wedding Dress Rehearsal Dresses | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Bridal Retail & Boutiques | Inventory for pre-wedding rehearsals and fittings | Enhances customer experience, increases upsell chances | Quality fabric, diverse sizing, regional style preferences |

| Event Planning & Wedding Services | Outfit supply for rehearsal dinners and related events | Streamlines event coordination, boosts client satisfaction | Timely delivery, adaptable styles for cultural nuances, durability |

| Fashion & Apparel Manufacturing | Prototype and sample dresses for design validation | Reduces production errors, accelerates time-to-market | Fabric quality, ease of customization, compliance with local standards |

| Rental & Leasing Services | Rental inventory for rehearsal dress needs | Cost-effective inventory management, expands customer base | Easy maintenance, durability, variety in styles and sizes |

| Online Wedding Marketplaces | Catalog offerings for virtual bridal consultations | Expands market reach, supports digital sales channels | High-resolution images, accurate sizing info, flexible return policies |

Wedding dress rehearsal dresses serve multiple pivotal roles across industries involved in the wedding ecosystem. In bridal retail and boutiques, these dresses are indispensable for pre-wedding fittings and rehearsal events. They allow brides to experience dress comfort and style before the big day, reducing last-minute alterations and enhancing overall customer satisfaction. For international buyers, especially from regions like Africa and South America, sourcing dresses that reflect local fashion sensibilities and sizing standards is critical to meet diverse client expectations.

In the event planning and wedding services sector, rehearsal dresses are essential for coordinating rehearsal dinners and ancillary wedding events. They provide a cohesive look and ensure that clients receive a seamless, culturally relevant experience. Buyers in the Middle East and Europe should prioritize suppliers who can offer timely deliveries and customizable designs that respect regional dress codes and traditions.

Fashion and apparel manufacturers utilize rehearsal dresses as prototypes or samples to test new designs. This application helps reduce costly production errors and accelerates the launch of new collections. For B2B buyers in Poland or Brazil, sourcing from manufacturers who provide high-quality fabrics and comply with local textile regulations ensures product reliability and market acceptance.

The rental and leasing services industry benefits from rehearsal dresses by maintaining a cost-effective inventory that caters to clients who prefer renting over purchasing. Durability and ease of cleaning are paramount considerations, making it necessary for buyers to select suppliers offering robust materials and a variety of styles that appeal to different cultural tastes.

Finally, online wedding marketplaces use rehearsal dresses as part of their digital catalogs to facilitate virtual bridal consultations and sales. This application expands market reach beyond geographic boundaries. For international B2B buyers, especially those targeting European and Middle Eastern markets, ensuring dresses come with accurate sizing information, high-quality images, and flexible return policies is crucial to building trust and driving conversions in an online environment.

Related Video: LABORATORY APPARATUS AND THEIR USES

Strategic Material Selection Guide for wedding dress rehearsal dresses

When selecting materials for wedding dress rehearsal dresses, international B2B buyers must carefully consider fabric properties that influence comfort, appearance, durability, and suitability for diverse climates and cultural preferences. Below is an analysis of four common materials widely used in rehearsal dresses, focusing on their performance characteristics, advantages, limitations, and implications for buyers from regions such as Africa, South America, the Middle East, and Europe.

Silk

Key Properties:

Silk is a natural protein fiber known for its smooth texture, excellent drape, and natural sheen. It is breathable, lightweight, and has moderate moisture-wicking capabilities. Silk can be delicate, requiring gentle handling and specific care.

Pros & Cons:

Silk offers a luxurious feel and elegant look, making it highly desirable for rehearsal dresses that emphasize sophistication. However, it is prone to wrinkling, can be expensive, and may require dry cleaning. Its delicate nature means it can be less durable for repeated use or rough handling.

Impact on Application:

Silk performs well in moderate to warm climates, providing comfort without overheating. Its natural fibers are hypoallergenic, appealing to sensitive skin. However, buyers should be aware of silk’s sensitivity to perspiration and sunlight, which can cause discoloration or weakening over time.

Considerations for International Buyers:

Buyers from humid regions like parts of Africa and South America should ensure silk is treated for moisture resistance or blended with synthetic fibers to enhance durability. Compliance with international textile standards such as OEKO-TEX® and ASTM for fiber content and safety is important. European and Middle Eastern markets often demand high-quality mulberry silk with certifications ensuring ethical sourcing.

Satin (Polyester or Silk Blend)

Key Properties:

Satin refers to the weave rather than the fiber, commonly produced from polyester, silk, or blends. It is characterized by a glossy surface and smooth texture. Polyester satin is more durable and wrinkle-resistant than pure silk satin.

Pros & Cons:

Satin offers a shiny, elegant appearance similar to silk but at a lower cost when polyester-based. It is easier to maintain and resistant to wrinkles, making it practical for rehearsal dresses. However, polyester satin is less breathable and can trap heat, which may reduce comfort in hot climates.

Impact on Application:

Satin is suitable for formal rehearsal dresses where a polished look is desired. Polyester satin’s durability suits high-volume production and repeated wear. However, in hot or humid environments (e.g., Middle East, tropical South America), it may cause discomfort unless designed with ventilation or lining.

Considerations for International Buyers:

Buyers should verify compliance with regional textile regulations such as REACH in Europe and local import standards in Africa and South America. Polyester satin’s cost-effectiveness makes it attractive in price-sensitive markets like Brazil and Poland. Ethical and environmental certifications (e.g., GRS for recycled polyester) are increasingly valued in European markets.

Chiffon (Polyester or Silk)

Key Properties:

Chiffon is a lightweight, sheer fabric with a slightly rough texture, commonly made from polyester or silk. It drapes well and offers a delicate, flowing silhouette. Polyester chiffon is more robust and easier to care for than silk chiffon.

Pros & Cons:

Chiffon provides an airy, romantic look ideal for rehearsal dresses that require movement and softness. It is lightweight and comfortable in warm climates. However, chiffon can snag easily and may require lining for opacity, increasing manufacturing complexity and cost.

Impact on Application:

Chiffon is favored in regions with warm weather such as much of Africa and South America due to its breathability. The fabric’s delicate nature means dresses must be handled carefully during production and retail. Polyester chiffon is more suitable for mass production and export due to its durability.

Considerations for International Buyers:

Buyers should consider fabric weight and opacity to meet regional modesty preferences, especially in Middle Eastern markets. Certifications for flame retardancy and chemical safety are important for compliance with European and international standards. Sourcing chiffon blends can optimize cost and performance for diverse markets.

Lace (Cotton or Synthetic Blends)

Key Properties:

Lace is an openwork fabric created through looping, braiding, or twisting threads. It can be made from cotton, polyester, nylon, or blends. Lace adds texture and intricate detail to rehearsal dresses and is often used as overlays or accents.

Pros & Cons:

Lace enhances aesthetic appeal with its delicate patterns and vintage charm. Cotton lace is breathable and natural but less durable and prone to shrinking. Synthetic lace offers greater durability and easier care but may lack the softness of natural fibers.

Impact on Application:

Lace is versatile and widely accepted across cultural markets for rehearsal dresses, often paired with other fabrics. It performs well in both warm and temperate climates but requires careful handling to avoid tearing. Synthetic blends are preferred for export due to better resilience during shipping.

Considerations for International Buyers:

Buyers should verify lace quality and compliance with international standards like ASTM D1388 (fabric stiffness) and EN ISO 14184 (formaldehyde content). Regional preferences vary: European markets often favor high-quality cotton lace, while synthetic blends are popular in cost-sensitive regions such as parts of Africa and South America.

Summary Table

| Material | Typical Use Case for wedding dress rehearsal dresses | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Silk | Elegant, high-end rehearsal dresses for moderate climates | Luxurious feel and natural breathability | Delicate, expensive, requires special care | High |

| Satin (Polyester or Silk Blend) | Formal rehearsal dresses needing glossy finish and durability | Cost-effective (polyester), wrinkle-resistant | Less breathable, may trap heat | Medium |

| Chiffon (Polyester or Silk) | Lightweight, flowing dresses for warm climates | Airy, romantic drape, comfortable | Prone to snagging, often requires lining | Medium |

| Lace (Cotton or Synthetic Blends) | Decorative overlays and accents on rehearsal dresses | Adds intricate texture and elegance | Can be delicate, cotton lace less durable | Varies (depends on blend) |

This guide equips international B2B buyers with critical insights to select materials that balance aesthetics, functionality, and market demands across diverse regions, ensuring optimal product offerings for wedding dress rehearsal dresses.

In-depth Look: Manufacturing Processes and Quality Assurance for wedding dress rehearsal dresses

Manufacturing Processes of Wedding Dress Rehearsal Dresses

The production of wedding dress rehearsal dresses involves a meticulous sequence of steps designed to ensure elegance, comfort, and durability. Understanding these stages enables B2B buyers to evaluate suppliers effectively and align with manufacturers who deliver consistent quality.

1. Material Preparation

High-quality fabric selection is fundamental. Common materials include satin, chiffon, lace, tulle, and organza, each requiring specific handling:

- Inspection and Sorting: Fabrics undergo visual and tactile inspection to detect flaws such as discoloration, holes, or uneven texture.

- Pre-treatment: Some fabrics require washing, steaming, or stretching to stabilize fibers and prevent shrinkage post-production.

- Cutting: Using manual or automated cutting machines, fabric is cut according to detailed patterns. Precision here minimizes waste and ensures uniformity across batches.

2. Forming and Shaping

This stage involves shaping the fabric pieces into components of the dress:

- Draping: Skilled artisans or CAD-assisted methods shape fabric on mannequins or forms to achieve desired silhouettes.

- Sewing: Industrial sewing machines stitch pieces together, using techniques such as French seams or flat-felled seams to enhance durability and aesthetics.

- Embroidery and Appliqué: Decorative elements are often added at this stage, either by hand or machine, which requires skilled craftsmanship to maintain design integrity.

3. Assembly

Assembly integrates all components into the final dress:

- Joining Bodice and Skirt: Precise alignment and stitching ensure the dress maintains its structure and fit.

- Attachment of Accessories: Zippers, buttons, hooks, and linings are added with attention to durability and ease of use.

- Quality Stitching Checks: Operators perform visual and manual checks for stitch tension, alignment, and thread quality to prevent defects.

4. Finishing

The finishing touches define the dress’s final look and feel:

- Pressing and Steaming: Ensures the garment is wrinkle-free and shapes are perfected.

- Trimming and Cleaning: Loose threads are trimmed, and any residues from manufacturing are cleaned off.

- Packaging: Dresses are carefully folded or hung in protective covers to prevent damage during transportation.

Quality Assurance (QA) and Quality Control (QC) in Production

For international B2B buyers, especially from diverse markets such as Africa, South America, the Middle East, and Europe, understanding and verifying the QC processes of wedding dress rehearsal dress manufacturers is essential to mitigate risks and ensure product excellence.

Illustrative Image (Source: Google Search)

Relevant International and Industry Standards

- ISO 9001: This global standard for quality management systems emphasizes consistent product quality, continuous improvement, and customer satisfaction. Suppliers certified to ISO 9001 demonstrate robust process controls and documentation.

- OEKO-TEX Standard 100: Particularly important for textile products, this certification assures that fabrics are free from harmful substances, an increasing concern for health-conscious markets.

- CE Marking: While primarily for safety-related products, CE compliance may be relevant if dresses include electronic elements (e.g., LED embellishments).

- Industry-Specific Standards: For buyers in regions like Europe or Brazil, local textile regulations and import standards may apply, requiring compliance documentation.

Key QC Checkpoints

- Incoming Quality Control (IQC): Raw materials (fabrics, accessories) are inspected upon arrival to ensure compliance with specifications. This step prevents defective inputs from entering production.

- In-Process Quality Control (IPQC): Continuous inspections occur at critical manufacturing stages, such as after cutting, sewing, and assembly. This real-time monitoring detects deviations early, reducing costly reworks.

- Final Quality Control (FQC): The completed dress undergoes comprehensive checks including measurements, fabric integrity, embellishment security, and overall appearance before packaging.

Common Testing Methods

- Fabric Strength and Durability Tests: Tensile strength and abrasion resistance tests ensure fabric can withstand wear during use.

- Colorfastness Testing: Assesses resistance to washing, rubbing, and light exposure to maintain dress appearance over time.

- Dimensional Stability: Verifies that dresses retain shape and size after laundering or pressing.

- Visual Inspections: Experienced inspectors check for flaws such as misaligned seams, puckering, or stains.

How B2B Buyers Can Verify Supplier Quality Control

To secure reliable supply chains, buyers should adopt a multi-faceted approach to QC verification:

- Factory Audits: Conduct on-site evaluations or hire third-party inspection agencies to assess manufacturing capabilities, worker skill levels, equipment quality, and compliance with international standards.

- Review of QC Documentation: Request ISO certificates, inspection reports, test result summaries, and corrective action records to confirm adherence to quality protocols.

- Third-Party Inspections: Employ independent inspection firms to perform random sampling and testing of goods before shipment, providing unbiased verification.

- Sample Orders: Prior to bulk purchase, order samples to evaluate workmanship, fabric quality, and finishing firsthand.

- Supplier Performance Metrics: Track defect rates, delivery punctuality, and responsiveness over time to build trust and identify improvement opportunities.

QC and Certification Nuances for International Buyers

Regional Considerations

- Africa: Some African markets prioritize affordability but are increasingly demanding quality certifications to align with global standards. Buyers should focus on suppliers with transparent QC systems and the ability to provide OEKO-TEX or ISO 9001 certifications.

- South America (e.g., Brazil): Import regulations may require documentation proving product safety and compliance with local textile standards. Buyers should verify supplier familiarity with these regulations to avoid customs delays.

- Middle East: Modesty and cultural preferences influence design and material choices. QC must ensure consistent fabric opacity and appropriate embellishments. Certifications related to chemical safety and non-toxicity are often required.

- Europe (e.g., Poland): European buyers often demand rigorous compliance with EU textile regulations and sustainability standards. Suppliers with ISO 9001 and environmental certifications have a competitive edge.

Logistics and Communication

International buyers must consider time zone differences, language barriers, and cultural factors when coordinating QC activities. Establishing clear communication channels and using digital tools for virtual audits or real-time reporting can enhance transparency.

Summary for B2B Buyers

- Understand the full manufacturing workflow from fabric selection to finishing to assess supplier capabilities.

- Demand adherence to international quality standards like ISO 9001 and OEKO-TEX to assure product safety and consistency.

- Implement comprehensive QC verification strategies including audits, documentation review, third-party inspections, and sample evaluations.

- Account for regional regulatory requirements and cultural preferences to ensure product acceptance in target markets.

- Foster transparent communication and long-term partnerships with manufacturers to adapt quickly to market trends and quality expectations.

By integrating these insights into procurement strategies, B2B buyers across Africa, South America, the Middle East, and Europe can confidently source wedding dress rehearsal dresses that meet exacting standards and delight end customers.

Related Video: Amazing Garment Manufacturing Process from Fabric to Finished Product Inside the Factory

Comprehensive Cost and Pricing Analysis for wedding dress rehearsal dresses Sourcing

Understanding the Cost Structure of Wedding Dress Rehearsal Dresses

When sourcing wedding dress rehearsal dresses, B2B buyers must carefully analyze the cost components that collectively determine the final price. Key cost factors include:

- Materials: Fabric choice (e.g., satin, chiffon, lace), embellishments (beads, embroidery), and accessories directly influence raw material costs. Premium materials often command higher prices but can justify a higher retail price.

- Labor: Skilled craftsmanship, especially for delicate detailing, significantly impacts costs. Regions with higher labor costs will reflect this in pricing.

- Manufacturing Overhead: Includes factory utilities, equipment depreciation, and indirect labor. Efficient factories with modern equipment can reduce these expenses.

- Tooling and Setup: Costs associated with pattern making, molds, and initial sample production. These are often one-time or infrequent but must be amortized over production runs.

- Quality Control (QC): Inspections and testing ensure dresses meet quality standards. Higher QC standards, often necessary for export markets, increase costs.

- Logistics: Shipping, customs duties, tariffs, and warehousing fees vary widely by destination. International buyers should factor in these costs to avoid surprises.

- Margin: Suppliers add profit margins based on market positioning and demand. Wholesale margins can vary from 20% to 50% depending on exclusivity and brand positioning.

Price Influencers and Their Impact on Sourcing Strategy

Several factors influence the pricing structure and should guide buyers during negotiations and supplier selection:

- Order Volume and Minimum Order Quantity (MOQ): Larger orders typically reduce unit costs due to economies of scale. However, buyers from emerging markets (e.g., African or South American countries) should balance MOQ with inventory risks.

- Product Specifications and Customization: Custom designs, special sizing, or unique embellishments increase complexity and cost. Standardized styles are generally more cost-effective.

- Material Quality and Certifications: Certified eco-friendly or sustainable fabrics may carry premiums but appeal to conscious consumers in Europe and the Middle East.

- Supplier Capabilities and Reputation: Established suppliers with reliable delivery and consistent quality may charge higher prices but reduce risk.

- Incoterms and Delivery Terms: Understanding terms like FOB, CIF, or DDP is critical. For example, buyers in Brazil or Poland might prefer DDP (Delivered Duty Paid) to avoid unexpected customs fees.

- Currency Fluctuations and Payment Terms: Volatility in exchange rates can affect landed costs. Negotiating favorable payment terms or currency clauses can mitigate risks.

Practical Buyer Tips for Cost-Efficient Sourcing

- Negotiate Beyond Price: Discuss payment terms, sample costs, lead times, and after-sales support. A supplier willing to accommodate flexible terms can improve cash flow and reduce risk.

- Calculate Total Cost of Ownership (TCO): Beyond purchase price, consider storage, customs clearance, quality returns, and potential markdowns due to quality issues.

- Leverage Volume Discounts Wisely: Consolidate orders when possible but avoid overstocking, which ties up capital and increases storage costs.

- Localize Logistics Planning: Partner with freight forwarders familiar with your region’s import regulations, especially in Africa and South America, to minimize delays and fees.

- Understand Pricing Nuances by Region: For example, Middle Eastern buyers may require more conservative designs and higher-quality finishes, affecting cost. European buyers often prioritize certifications and sustainability, influencing material costs.

- Request Transparent Cost Breakdowns: Insist suppliers provide itemized cost sheets to identify potential savings and verify fairness.

- Plan for Currency and Tax Implications: Engage financial advisors to optimize currency exchange strategies and comply with VAT or import tax requirements in your jurisdiction.

Indicative Pricing Disclaimer

Prices for wedding dress rehearsal dresses vary widely depending on material quality, design complexity, order volume, and supplier location. As a general reference, wholesale prices can range from $50 to $300+ per dress, exclusive of shipping and import duties. Buyers should conduct due diligence and request formal quotations tailored to their specific requirements.

By thoroughly analyzing these cost and pricing factors, international B2B buyers can optimize sourcing strategies, negotiate effectively, and ensure competitive pricing for wedding dress rehearsal dresses in diverse global markets.

Spotlight on Potential wedding dress rehearsal dresses Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘wedding dress rehearsal dresses’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for wedding dress rehearsal dresses

Key Technical Properties of Wedding Dress Rehearsal Dresses

When sourcing wedding dress rehearsal dresses for international B2B trade, understanding critical technical properties ensures product quality, consistency, and market fit. These specifications help buyers assess supplier capabilities and manage customer expectations effectively.

-

Fabric Quality and Grade

The fabric is the foundation of rehearsal dresses, commonly using materials like satin, chiffon, lace, or organza. Fabric quality is graded by thread count, fiber type (natural vs. synthetic), and finishing processes. High-grade fabrics offer better drape, durability, and comfort. For B2B buyers, specifying fabric grade upfront reduces returns and aligns with target market preferences, particularly in regions with varying climate demands such as humid tropical areas in Africa or colder European climates. -

Color Fastness and Consistency

Color fastness refers to the fabric’s resistance to fading or bleeding during washing and exposure to light. Consistent color matching across batches is crucial for maintaining brand reputation and customer satisfaction. This property is especially important when coordinating rehearsal dresses with wedding themes or bridal party attire, and for buyers serving diverse international markets where color preferences vary. -

Size Tolerance and Fit Standards

Size tolerance defines acceptable deviations from specified garment measurements (e.g., ±1 cm). Rehearsal dresses often come in standard sizes but may require custom sizing or inclusive sizing ranges. Reliable size tolerance ensures dresses fit well, minimizing alterations and returns. This is vital for international buyers targeting regions like South America or the Middle East, where body shapes and sizing standards differ from Western norms. -

Seam Strength and Stitching Quality

Seam strength measures how well the dress holds together under stress, influenced by stitch type, density, and thread quality. High seam integrity guarantees longevity through multiple wears and fittings. For wholesalers and retailers, this reduces product defects and warranty claims, ensuring a trustworthy supplier relationship. -

Embellishment Durability

Many rehearsal dresses feature embellishments like beads, sequins, or embroidery. The durability of these decorative elements affects overall dress quality and customer satisfaction. Buyers should verify that embellishments are securely attached and resistant to shedding, especially when dresses are intended for multiple uses or events. -

Care and Maintenance Instructions

Clear specifications on recommended cleaning methods (e.g., dry clean only, hand wash) impact customer usability and product lifecycle. Understanding these instructions helps B2B buyers provide accurate product information to end customers, reducing dissatisfaction and damage during care.

Common Trade Terminology for Wedding Dress Rehearsal Dresses

Navigating international B2B transactions requires familiarity with key industry terms that clarify order processes, costs, and responsibilities.

-

OEM (Original Equipment Manufacturer)

Refers to suppliers producing dresses under the buyer’s brand name. OEM partnerships allow customization of design, labels, and packaging, enabling buyers to build exclusive collections. This is ideal for boutiques and retailers seeking differentiation in competitive markets like Europe or South America. -

MOQ (Minimum Order Quantity)

The smallest number of units a supplier is willing to produce per order. MOQs vary widely based on supplier capacity and production complexity. Understanding MOQ helps buyers manage inventory risks and negotiate terms suited to their market size, especially important for emerging businesses in Africa and the Middle East. -

RFQ (Request for Quotation)

A formal inquiry sent to suppliers requesting pricing, lead times, and terms based on specified product requirements. RFQs are essential for comparing multiple suppliers efficiently and securing the best value without compromising quality. -

Incoterms (International Commercial Terms)

Standardized trade terms defining responsibilities, risks, and costs between buyers and sellers during shipment. Common terms include FOB (Free On Board), CIF (Cost, Insurance, Freight), and DDP (Delivered Duty Paid). Selecting appropriate Incoterms impacts logistics, customs clearance, and overall cost management, crucial for cross-continental trade involving Africa, Europe, or South America. -

Lead Time

The total time from order confirmation to delivery. Lead times vary by production complexity and shipping method. Accurate lead time estimates are critical for planning inventory and meeting seasonal demand cycles, such as wedding seasons that differ regionally. -

Sample Approval

The process where buyers review physical or digital dress samples before mass production. Sample approval mitigates risks related to quality, fit, and design discrepancies. It is a vital step in establishing trust and ensuring product alignment with market expectations.

By mastering these technical properties and trade terms, international B2B buyers can make informed sourcing decisions, optimize supplier relationships, and successfully cater to diverse wedding dress rehearsal markets across Africa, South America, the Middle East, and Europe.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the wedding dress rehearsal dresses Sector

Market Overview & Key Trends

The global market for wedding dress rehearsal dresses is experiencing dynamic growth, driven by increasing consumer demand for personalized and culturally resonant bridal experiences. For international B2B buyers from regions such as Africa, South America, the Middle East, and Europe, understanding regional preferences and sourcing trends is crucial. In countries like Brazil and Poland, buyers seek diverse styles that blend traditional aesthetics with modern influences, reflecting local customs and evolving fashion sensibilities.

Key market drivers include rising disposable incomes, expanding wedding industries, and the growing influence of social media platforms that showcase rehearsal dress trends. Buyers are increasingly focusing on versatile, elegant dresses that can transition from rehearsal dinners to other formal occasions, which broadens market appeal and inventory diversity.

Technology adoption is reshaping sourcing and supply chain management. Digital showrooms and virtual sampling allow buyers from distant markets to evaluate collections without physical travel, reducing lead times and costs. Additionally, data analytics tools help predict style preferences and size distributions, enabling more precise inventory planning. For B2B buyers in emerging markets, leveraging these digital tools can improve sourcing efficiency and responsiveness to fast-changing trends.

The market also sees a growing preference for customization and made-to-order models, supported by advanced manufacturing technologies such as automated cutting and sewing. This trend aligns with the desire for unique rehearsal dresses that cater to a wide range of body types and cultural styles. Collaborative partnerships with designers and manufacturers are increasingly important for international buyers to secure exclusive collections and maintain competitive differentiation.

Sustainability & Ethical Sourcing in B2B

Sustainability has become a pivotal consideration in the wedding dress rehearsal dresses sector. The environmental impact of textile production, dyeing, and garment manufacturing is significant, prompting B2B buyers to prioritize eco-friendly sourcing. International buyers are increasingly demanding transparency in supply chains to ensure ethical labor practices and reduce carbon footprints.

Illustrative Image (Source: Google Search)

Key sustainability practices include sourcing organic or recycled fabrics such as organic cotton, Tencel, and recycled polyester. These materials reduce water consumption and chemical use compared to conventional textiles. Certifications like Global Organic Textile Standard (GOTS), OEKO-TEX Standard 100, and Bluesign provide credible assurance of sustainable material sourcing and production processes.

Ethical sourcing also involves partnering with suppliers who uphold fair labor standards and safe working conditions. For buyers from regions with strong regulatory environments, such as the EU, compliance with labor laws and human rights standards is not only a legal necessity but also a market expectation that can enhance brand reputation.

Circular economy initiatives, including fabric recycling programs and zero-waste pattern making, are gaining traction. B2B buyers can drive sustainability by collaborating with manufacturers offering take-back schemes or producing rehearsal dresses designed for multiple uses, thereby extending product lifecycle and reducing waste.

Brief Evolution and Historical Context

Historically, rehearsal dresses have evolved from simple, modest attire worn during pre-wedding ceremonies to sophisticated fashion statements integral to bridal celebrations. Initially, these dresses emphasized practicality and modesty, often mirroring the wedding dress silhouette but in less elaborate fabrics.

Over the past two decades, the rise of bridal culture and social media exposure transformed rehearsal dresses into an opportunity for style experimentation. Buyers now demand a range of designs—from minimalist chic to embellished glamour—reflecting diverse cultural rituals and personal tastes. This evolution underscores the importance for B2B buyers to stay attuned to shifting fashion cycles and regional nuances to meet the sophisticated needs of contemporary bridal markets.

Related Video: Global Trends Chapter 2 | Part 1 | Video Posted!

Frequently Asked Questions (FAQs) for B2B Buyers of wedding dress rehearsal dresses

-

How can I effectively vet suppliers of wedding dress rehearsal dresses for international B2B sourcing?

To vet suppliers, start by verifying their business licenses and certifications to ensure legitimacy. Request product samples to assess quality firsthand. Check references and online reviews from other B2B buyers, especially those from your region. Evaluate their production capacity, communication responsiveness, and willingness to provide customization options. For buyers from Africa, South America, the Middle East, and Europe, consider suppliers with experience exporting to your markets to minimize compliance issues. Using third-party inspection services can add an extra layer of quality assurance before finalizing contracts. -

Is customization of wedding dress rehearsal dresses commonly available from manufacturers, and what should I consider?

Many manufacturers offer customization including fabric choice, sizing, embellishments, and design modifications. When negotiating, clarify minimum order quantities (MOQs) for custom pieces as they can be higher than standard items. Confirm lead times for custom production to align with your inventory planning. Provide detailed tech packs or design references to avoid misunderstandings. Additionally, discuss intellectual property rights and exclusivity if you want unique designs. Customization can differentiate your product offering but requires clear communication and contractual safeguards. -

What are typical minimum order quantities (MOQs) and lead times for international orders of rehearsal dresses?

MOQs vary widely depending on supplier scale and customization level, typically ranging from 50 to 200 units per style. For basic, off-the-shelf rehearsal dresses, some suppliers accept smaller MOQs, beneficial for smaller boutiques. Lead times generally range from 30 to 90 days, influenced by order size, customization, and supplier location. Buyers should factor in extra time for shipping and customs clearance. Negotiating flexible MOQs and expedited production options can be possible with established suppliers, especially if you commit to repeat orders.

Illustrative Image (Source: Google Search)

-

What payment terms and methods are standard in international B2B transactions for wedding dress rehearsal dresses?

Common payment terms include a 30%-50% deposit upfront with the balance paid before shipment or upon delivery. Payment methods often include wire transfers (T/T), Letters of Credit (L/C), and escrow services. For newer suppliers, Letters of Credit provide security by involving banks in payment release upon meeting contract terms. Established relationships may allow net terms (e.g., 30 days post-delivery). Always confirm currency used and any transaction fees. Using trade finance solutions or payment platforms with escrow can mitigate risks in cross-border transactions. -

How do I ensure quality assurance and compliance with international standards when importing rehearsal dresses?

Request suppliers to provide quality certifications such as ISO 9001 or compliance with specific textile standards relevant to your market (e.g., OEKO-TEX for chemical safety). Insist on pre-shipment quality inspections either by in-house teams or third-party agencies. Samples should be approved before bulk production. Maintain a clear quality checklist that covers stitching, fabric, sizing accuracy, and packaging. Understanding your country’s import regulations and labeling requirements ensures compliance, reducing the risk of customs delays or product rejections. -

What logistics considerations should I be aware of when importing wedding dress rehearsal dresses internationally?

Choose suppliers experienced with international shipping and familiar with your region’s customs regulations. Decide between air freight for faster delivery or sea freight for cost efficiency based on order urgency and size. Clarify Incoterms (e.g., FOB, CIF) to understand your responsibilities and costs at each shipping stage. Coordinate with reliable freight forwarders and customs brokers to handle documentation and clearance. Factor in possible delays due to customs inspections or seasonal demand spikes. Transparent communication with suppliers about shipping schedules is critical for inventory planning.

-

How should I handle disputes or quality issues with overseas suppliers?

Establish clear dispute resolution terms in your contract, including timelines for reporting defects and remedies such as replacement, refund, or discount. Document all communications and inspect shipments immediately upon arrival. Use third-party inspection reports as evidence if disputes arise. For ongoing partnerships, consider involving mediators or arbitration services specializing in international trade. Maintaining professional and prompt communication helps resolve issues amicably. Building strong relationships with suppliers who prioritize customer satisfaction reduces dispute risks. -

Are there specific challenges or opportunities when sourcing rehearsal dresses from suppliers in Asia for markets in Africa, South America, the Middle East, and Europe?

Asian suppliers often offer competitive pricing and extensive manufacturing expertise in wedding attire, presenting cost-effective sourcing opportunities. However, challenges include longer shipping times, potential language barriers, and differing quality expectations. Buyers should invest in thorough supplier vetting and establish clear product specifications. Leveraging trade shows, sourcing agents, or local offices can improve communication. Additionally, consider regional trade agreements and tariffs impacting costs. Proper planning and relationship-building enable buyers to capitalize on Asia’s manufacturing strengths while minimizing logistical and cultural challenges.

Strategic Sourcing Conclusion and Outlook for wedding dress rehearsal dresses

Strategic sourcing in the wedding dress rehearsal market demands a nuanced approach tailored to the diverse preferences and cultural nuances of international buyers, especially those from Africa, South America, the Middle East, and Europe. Key takeaways emphasize the importance of partnering with reputable suppliers who offer high-quality, versatile collections that cater to varying sizes, styles, and price points. Leveraging data on regional trends and customer expectations can enhance inventory selection and marketing strategies, ensuring relevance in competitive markets like Brazil and Poland.

Prioritizing supplier reliability, transparent communication, and flexible logistics will minimize risks and optimize supply chain efficiency. Additionally, investing in strong relationships with manufacturers who understand local market dynamics can unlock exclusive collections and foster innovation.

Looking ahead, the wedding dress rehearsal segment is poised for growth driven by rising global demand for unique, culturally resonant bridal experiences. International B2B buyers are encouraged to adopt a strategic sourcing mindset—balancing cost, quality, and adaptability—to capitalize on emerging opportunities. By doing so, businesses can position themselves as trusted partners in delivering memorable bridal moments worldwide, driving sustainable success in a vibrant, evolving industry.