Your Ultimate Guide to Sourcing Mens Black Dress Shirt

Guide to Mens Black Dress Shirt

- Introduction: Navigating the Global Market for mens black dress shirt

- Understanding mens black dress shirt Types and Variations

- Key Industrial Applications of mens black dress shirt

- Strategic Material Selection Guide for mens black dress shirt

- In-depth Look: Manufacturing Processes and Quality Assurance for mens black dress shirt

- Comprehensive Cost and Pricing Analysis for mens black dress shirt Sourcing

- Spotlight on Potential mens black dress shirt Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for mens black dress shirt

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the mens black dress shirt Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of mens black dress shirt

- Strategic Sourcing Conclusion and Outlook for mens black dress shirt

Introduction: Navigating the Global Market for mens black dress shirt

The men’s black dress shirt stands as a timeless staple in professional wardrobes worldwide, symbolizing sophistication, versatility, and enduring style. For international B2B buyers, particularly those operating in dynamic markets such as Africa, South America, the Middle East, and Europe, sourcing high-quality black dress shirts presents both an opportunity and a challenge. Understanding the nuances of fabric selection, manufacturing processes, quality control, and supplier reliability is essential to secure competitive advantage and meet diverse market demands.

This comprehensive guide is designed to equip buyers from regions including Colombia, Kenya, and beyond with actionable insights to navigate the global supply landscape effectively. It covers a wide spectrum of critical topics: from the various types and styles of men’s black dress shirts, through material characteristics and sourcing strategies, to in-depth exploration of manufacturing workflows and stringent quality assurance practices. Additionally, the guide examines key market trends, cost considerations, and supplier evaluation frameworks, ensuring buyers can optimize procurement decisions with confidence.

By consolidating expert knowledge and practical advice, this resource empowers B2B buyers to mitigate risks, enhance product quality, and foster sustainable supplier relationships. Whether you are expanding your product portfolio or entering new markets, this guide provides the strategic foundation needed to succeed in the competitive realm of men’s black dress shirts. Embrace this opportunity to transform your sourcing approach and deliver exceptional value to your customers worldwide.

Understanding mens black dress shirt Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Classic Fit Black Dress Shirt | Relaxed fit, traditional collar, standard cuff styles | Corporate uniforms, formal events, retail chains | Pros: Comfortable for all-day wear, broad appeal; Cons: Less tailored, may seem outdated in fashion-forward markets |

| Slim Fit Black Dress Shirt | Tapered cut, narrow collar, fitted sleeves | Fashion retail, upscale hospitality, executive wear | Pros: Modern look, appeals to younger demographics; Cons: Limited sizing flexibility, less comfortable for larger sizes |

| Performance Fabric Black Shirt | Moisture-wicking, wrinkle-resistant, stretch materials | Sports management, travel-oriented businesses, outdoor events | Pros: Easy care, durable; Cons: Higher cost, may lack traditional formal appearance |

| French Cuff Black Dress Shirt | Double cuffs requiring cufflinks, often with spread collar | Luxury retail, formal events, high-end corporate gifting | Pros: Premium appeal, customizable; Cons: Higher price point, requires cufflinks |

| Patterned/Texture Black Shirt | Subtle textures (e.g., herringbone, jacquard) or minimal patterns | Boutique fashion, creative industries, evening wear | Pros: Unique aesthetic, differentiates product lines; Cons: May not suit all formal dress codes |

Classic Fit Black Dress Shirt

The classic fit black dress shirt is characterized by its relaxed cut and traditional styling, making it a staple for corporate uniforms and formal occasions. Its broad sizing accommodates diverse markets, which is advantageous for international buyers targeting mass retail or uniform supply. Buyers should consider the shirt’s versatility and comfort but be aware that its conventional style might not appeal to younger or trend-conscious consumers in evolving fashion hubs such as Nairobi or Bogotá.

Slim Fit Black Dress Shirt

Designed with a tapered silhouette and narrow collars, the slim fit black dress shirt caters to markets emphasizing contemporary fashion and elegance. It is well-suited for upscale hospitality sectors and executive wardrobes. B2B buyers should evaluate their target demographic carefully, as this style offers limited flexibility for larger sizes but can command higher margins in fashion-forward regions like Dubai or European capitals.

Performance Fabric Black Shirt

Incorporating advanced textiles that wick moisture, resist wrinkles, and provide stretch, performance fabric black shirts meet the demands of active professionals and travelers. These shirts are ideal for businesses involved in sports management, tourism, or outdoor events across Africa and South America. Buyers must balance the higher production costs against the value offered by durability and ease of maintenance, which can be a strong selling point in climates with high humidity or frequent travel.

French Cuff Black Dress Shirt

Recognizable by its double cuff design requiring cufflinks, the French cuff shirt embodies luxury and sophistication. This variation is favored in premium retail and formal event markets, often serving as corporate gifts or high-end inventory. International buyers should account for the additional accessory requirements and higher price points, targeting affluent customers or niche markets in the Middle East and Europe.

Patterned/Texture Black Shirt

These shirts feature subtle patterns or textures such as herringbone or jacquard weaves, offering a distinctive alternative to plain black shirts. They appeal to boutique retailers and creative industries seeking to differentiate their product lines. While adding aesthetic value, buyers must ensure these variations align with local formal dress codes and consumer preferences, especially in conservative markets where understated elegance is preferred.

Related Video: Men’s Dress Shirt Styles – How To Choose the Perfect Collar, Placket, Cuff & Fit

Key Industrial Applications of mens black dress shirt

| Industry/Sector | Specific Application of mens black dress shirt | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Hospitality & Catering | Uniforms for waitstaff and event personnel | Enhances professional appearance and brand consistency | Durable fabric, stain resistance, comfortable fit for long shifts |

| Corporate & Business | Formal office wear and client-facing roles | Projects professionalism and authority, suitable for meetings | High-quality fabric, precise tailoring, availability in multiple sizes |

| Entertainment & Events | Stage and event staff uniforms | Provides a sleek, uniform look that complements event aesthetics | Breathable material, wrinkle resistance, easy maintenance |

| Retail & Fashion | Display and promotional staff uniforms | Creates a cohesive brand image and improves customer perception | Trend-aligned designs, fabric quality, and customization options |

| Security Services | Uniform shirts for security personnel | Conveys authority and professionalism, durable for active roles | Reinforced stitching, comfortable fit, and moisture-wicking fabric |

Hospitality & Catering

In the hospitality sector, men’s black dress shirts serve as essential uniforms for waitstaff and event personnel. They contribute significantly to the professional ambiance that high-end restaurants and hotels aim to create. These shirts need to withstand frequent laundering and resist stains from food and beverages, which is critical for maintaining a polished appearance throughout long shifts. Buyers from regions like Kenya and Colombia should prioritize sourcing shirts made from durable, stain-resistant fabrics with comfortable cuts to ensure staff comfort and longevity of the garment under heavy use.

Corporate & Business

Corporate environments across Africa, South America, the Middle East, and Europe often require formal dress codes where men’s black dress shirts are a staple. These shirts play a vital role in projecting professionalism and confidence during client meetings, presentations, and daily office wear. International B2B buyers should focus on shirts with high-quality fabrics such as cotton blends that offer breathability and wrinkle resistance. Precise tailoring and availability in a range of sizes are crucial to meet diverse workforce needs and regional body types.

Entertainment & Events

For the entertainment industry and event management companies, men’s black dress shirts are often used as uniforms for stagehands, ushers, and event coordinators. The sleek black color complements various event themes while maintaining a uniform look. Buyers from the Middle East and Europe should look for breathable, wrinkle-resistant materials that ensure comfort during long hours of work and quick transitions between events. Easy maintenance is also a key factor, allowing for rapid turnaround in laundering and preparation.

Retail & Fashion

Retail chains and fashion brands frequently outfit their sales and promotional staff in men’s black dress shirts to reinforce brand identity and professionalism. These shirts help create a cohesive look that enhances customer experience and brand perception. Sourcing considerations for buyers in South America and Africa include fabrics that align with current fashion trends, options for customization such as logos or embroidery, and a balance between quality and cost-effectiveness to support large-volume orders.

Security Services

Security personnel across various sectors rely on men’s black dress shirts as part of their uniform to convey authority and professionalism. These shirts must be durable to withstand physical activity and environmental conditions while providing comfort during extended shifts. Buyers in regions like Kenya and Colombia should prioritize shirts with reinforced stitching, moisture-wicking properties, and ergonomic fits to ensure functionality and durability in demanding security roles.

Strategic Material Selection Guide for mens black dress shirt

When selecting materials for men’s black dress shirts, international B2B buyers must consider fabric properties that affect comfort, durability, appearance, and suitability for diverse climates and markets. Below is an in-depth analysis of four common materials — cotton, polyester, cotton-polyester blends, and lyocell — highlighting their key characteristics, advantages, limitations, and regional considerations relevant to buyers from Africa, South America, the Middle East, and Europe.

Cotton

Key Properties:

Cotton is a natural cellulose fiber known for breathability, moisture absorption, and softness. It performs well in moderate to warm climates, offering good thermal regulation. Cotton fabrics typically have medium tensile strength and moderate wrinkle resistance.

Pros & Cons:

Cotton shirts provide excellent comfort and a premium look, making them ideal for formal wear. However, 100% cotton tends to wrinkle easily and may shrink if not pre-treated. It requires more complex manufacturing steps like mercerization or combing to enhance fabric quality. Durability is moderate, with susceptibility to fading in black shades if low-quality dyes are used.

Impact on Application:

Cotton is highly compatible with various dyeing and finishing processes, allowing deep, rich black colors that appeal to fashion-conscious markets. It suits buyers targeting regions with warm or humid climates (e.g., Kenya, Colombia) due to its breathability. However, cotton’s moisture absorption can be a drawback in very humid or rainy areas, requiring buyers to consider fabric treatments for quick drying.

Regional Considerations:

Buyers in Europe and the Middle East often demand compliance with OEKO-TEX or GOTS certifications to ensure sustainable and chemical-safe cotton sourcing. African and South American markets may prioritize cost-effective cotton grades but increasingly seek organic or fair-trade certifications. Standards like ASTM D3775 (fabric count) and ISO 105-B02 (colorfastness) are relevant for quality assurance.

Polyester

Key Properties:

Polyester is a synthetic fiber characterized by high tensile strength, wrinkle resistance, and quick drying. It is hydrophobic, meaning it resists moisture absorption, which can be beneficial in humid climates. Polyester fabrics generally have excellent color retention, especially in dark shades like black.

Pros & Cons:

Polyester shirts are durable, low-maintenance, and cost-effective, making them attractive for bulk production. However, polyester lacks breathability, which can reduce wearer comfort in hot climates. The fabric may feel less natural and can generate static electricity. Manufacturing polyester shirts is relatively straightforward, with fewer finishing requirements.

Impact on Application:

Polyester’s moisture-wicking and quick-dry properties are advantageous for buyers targeting Middle Eastern and African markets where heat and sweat are concerns. Its resistance to fading ensures longevity of black color, important for maintaining premium appearance. However, polyester’s lower comfort level may limit appeal in premium European markets.

Regional Considerations:

Compliance with REACH regulations in Europe and OEKO-TEX certification is crucial to ensure polyester garments meet safety and environmental standards. Buyers in South America and Africa should evaluate suppliers’ adherence to local import regulations and quality standards like ASTM D5034 (breaking strength).

Cotton-Polyester Blend

Key Properties:

Blended fabrics combine cotton’s breathability with polyester’s durability and wrinkle resistance. Typical blends range from 60/40 to 50/50 cotton/polyester ratios, balancing comfort and performance. The blend reduces shrinkage and improves color retention compared to pure cotton.

Pros & Cons:

Blends offer a cost-effective solution with easier care and longer lifespan than pure cotton. They wrinkle less and dry faster but may compromise some natural softness and breathability. Manufacturing complexity increases slightly due to the need for specialized dyeing and finishing processes that accommodate both fibers.

Impact on Application:

Cotton-polyester blends are versatile for diverse climates, providing comfort in warm regions like Colombia and Kenya while maintaining durability for European markets. The blend’s resilience to wear and tear suits high-volume B2B orders targeting retail chains or uniforms.

Regional Considerations:

Buyers should verify blend ratios and fabric certifications to meet market-specific standards. For example, European buyers often require compliance with OEKO-TEX Standard 100 and REACH. Middle Eastern and African buyers may prioritize cost and durability but increasingly value eco-friendly blends.

Lyocell (TENCEL®)

Key Properties:

Lyocell is a regenerated cellulose fiber derived from sustainably sourced wood pulp. It is highly breathable, moisture-wicking, and softer than cotton. Lyocell fabrics have excellent drape, good tensile strength, and resist wrinkles better than cotton.

Pros & Cons:

Lyocell shirts offer superior comfort and a luxurious feel, appealing to premium segments. The fabric is biodegradable and environmentally friendly, aligning with growing sustainability demands. However, lyocell is more expensive and requires careful handling during manufacturing to prevent fiber damage.

Impact on Application:

Ideal for buyers targeting eco-conscious markets in Europe and upscale retailers in South America and the Middle East. Its moisture management properties make it suitable for hot and humid climates. Lyocell’s premium positioning may limit volume orders but enhances brand value.

Regional Considerations:

Sustainability certifications such as FSC and OEKO-TEX are critical for lyocell products. Buyers should ensure suppliers comply with international environmental standards and verify fiber origin. In Africa and South America, lyocell is emerging but may face supply chain constraints and higher costs.

| Material | Typical Use Case for mens black dress shirt | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Cotton | Premium formal shirts for moderate to warm climates | Breathable, comfortable, natural fiber | Prone to wrinkles, moderate durability | Medium |

| Polyester | Cost-effective, durable shirts for hot/humid regions | Wrinkle-resistant, quick-drying, colorfast | Less breathable, synthetic feel | Low |

| Cotton-Polyester Blend | Versatile shirts balancing comfort and durability | Combines softness with durability | Slightly less natural feel, moderate complexity | Medium |

| Lyocell (TENCEL®) | Premium eco-friendly shirts for upscale markets | Soft, breathable, sustainable | Higher cost, delicate manufacturing requirements | High |

In-depth Look: Manufacturing Processes and Quality Assurance for mens black dress shirt

Manufacturing a high-quality men’s black dress shirt involves a series of precise, well-coordinated processes from raw material preparation to final finishing. For international B2B buyers, especially those in Africa, South America, the Middle East, and Europe, understanding these manufacturing stages and the embedded quality assurance (QA) protocols is essential for sourcing reliable suppliers and ensuring product consistency.

Manufacturing Process Overview

1. Material Preparation and Inspection

-

Fabric Sourcing: The foundation of a premium black dress shirt is the fabric, typically high-grade cotton, cotton blends, or technical textiles with specific properties like wrinkle resistance or breathability. Factories source fabric directly from mills to ensure consistency in color and quality, often specifying fabric weight, weave type (e.g., poplin, twill), and color fastness, critical for deep black tones.

-

Trims and Accessories: Buttons (commonly black or matte finish for dress shirts), threads, interlinings (fusible or sew-in for collar and cuff structure), and labels are sourced alongside fabric. These must meet durability and aesthetic standards.

-

Incoming Quality Control (IQC): Upon receipt, fabrics and trims undergo rigorous inspection. Fabric inspection machines or manual checks identify defects like shade variation, weaving faults, or color inconsistencies. For black fabric, shade uniformity is particularly scrutinized to avoid visible mismatches in finished shirts.

2. Pattern Making and Cutting

-

Pattern Development: Using CAD systems, factories create graded patterns for multiple sizes (S, M, L, XL). This step ensures consistent fit and minimizes fabric waste through optimized marker layouts.

-

Cutting: Fabric layers are stacked and cut precisely using automated cutting machines. For black dress shirts, particular attention is given to fabric grain alignment and matching fabric patterns (if any) to maintain aesthetic integrity. Fusible interlinings are cut simultaneously for efficient assembly.

3. Assembly and Sewing

-

Parts Formation: Collar, cuffs, front plackets, sleeves, and pocket components are sewn separately. High-precision machines (e.g., flat-bed, overlock, and bar-tack machines) are employed to ensure seam strength and neat finishes.

-

Line Production: In factory settings, a multi-operator assembly line approach is common, where each operator specializes in a single sewing operation. This specialization enhances efficiency and quality control at each step.

-

Specialized Sewing Techniques: For dress shirts, topstitching on collars and cuffs adds durability and style. Buttonholes are often made using automatic buttonhole machines to ensure uniformity. Seam reinforcement at stress points is standard.

4. Finishing

-

Button Attachment: Buttons are sewn with precision, often with reinforced stitching or shank buttons to improve durability and appearance.

-

Pressing and Quality Checks: Finished shirts undergo pressing to remove wrinkles and shape the garment. This step also helps in final inspection for defects such as loose threads, seam puckering, or staining.

-

Packing: Shirts are folded uniformly and packed with protective materials to prevent damage during shipment. For export, packaging often includes branded or neutral polybags and cartons that comply with international shipping standards.

Quality Assurance (QA) Framework

Effective QA in men’s black dress shirt manufacturing is multi-tiered, incorporating international standards and industry-specific checkpoints to guarantee product consistency, safety, and compliance.

Key International Standards

-

ISO 9001: This global standard for quality management systems (QMS) ensures that manufacturers implement consistent processes, continuous improvement, and customer satisfaction mechanisms. For B2B buyers, sourcing from ISO 9001-certified factories minimizes risks related to quality inconsistency.

-

Industry-Specific Certifications: Although not garment-specific, certifications like OEKO-TEX Standard 100 (for harmful substances) and GOTS (for organic textiles) may apply depending on material sourcing. Compliance with chemical safety and environmental standards is increasingly demanded by global markets.

-

Regional Regulatory Compliance: Buyers from Europe, for example, may require REACH compliance for chemical safety, while buyers from the Middle East or Africa might focus on import regulations and local textile standards.

QC Checkpoints in Production

-

Incoming Quality Control (IQC): As described, IQC inspects raw materials before production. This stage is critical for ensuring fabric shade uniformity and defect-free trims.

-

In-Process Quality Control (IPQC): During cutting, sewing, and assembly, IPQC teams monitor adherence to technical specifications, including stitch density, seam strength, button placement, and dimensional accuracy.

-

Final Quality Control (FQC): Before packing, the finished shirts undergo final inspection for appearance, fit, and functional attributes. Checks include:

-

Color consistency and shade matching across batches

- Seam and stitch integrity

- Button and buttonhole durability

- Labeling and packaging accuracy

Common Testing Methods

-

Colorfastness Tests: Evaluates resistance of black fabric to washing, rubbing, and light exposure to prevent fading.

-

Dimensional Stability: Assesses shrinkage after washing to ensure size retention.

-

Tensile and Seam Strength Tests: Confirms durability of fabric and stitches under stress.

-

Chemical Testing: Verifies absence of harmful substances, important for OEKO-TEX certification and regulatory compliance.

Verifying Supplier Quality Assurance: Best Practices for B2B Buyers

Supplier Audits

-

Factory Audits: On-site inspections by buyers or third-party audit firms assess factory compliance with ISO standards, labor practices, production capacity, and QA processes.

-

Process Audits: Focus on specific production stages, verifying adherence to technical specifications and quality checkpoints.

Documentation and Reporting

-

Quality Control Reports: Detailed reports on IQC, IPQC, and FQC results provide transparency on defect rates, corrective actions, and batch traceability.

-

Certifications and Test Reports: Buyers should request copies of relevant certifications (ISO 9001, OEKO-TEX) and independent lab test results for fabrics and finished garments.

Third-Party Inspections

-

Pre-shipment Inspections (PSI): Independent agencies conduct random sampling and testing of finished shirts before shipment to confirm quality standards.

-

Laboratory Testing: Samples sent to accredited labs for colorfastness, shrinkage, and chemical safety testing can validate supplier claims.

QC and Certification Nuances for International Buyers from Africa, South America, Middle East, and Europe

-

Adaptation to Regional Standards: Buyers from Europe may prioritize sustainability certifications and chemical safety (REACH), while African and South American buyers might emphasize cost-effective quality assurance combined with compliance to local import regulations.

-

Shade Consistency for Black Shirts: In markets with high humidity (e.g., parts of Africa and South America), fabric dyeing and finishing processes must account for environmental factors to avoid shade variation and fading.

-

Communication and Transparency: For regions with limited direct access to suppliers, investing in digital quality management platforms or local inspection services can bridge gaps in oversight.

-

Cultural and Market Preferences: Certain markets may prefer specific fabric weights or finishes for black dress shirts, requiring suppliers to customize production runs accordingly and maintain consistent QA records to meet those preferences.

-

Logistics and Packaging Compliance: Export packaging should comply with international shipping standards and local import requirements (e.g., labeling in local languages, adherence to environmental packaging norms).

Summary: Actionable Insights for B2B Buyers

-

Prioritize suppliers with certified QMS (ISO 9001) and transparent QA documentation.

-

Ensure fabric sourcing includes stringent shade and colorfastness controls, critical for black dress shirts.

-

Request detailed QC checkpoints and inspection reports covering IQC, IPQC, and FQC stages.

-

Leverage third-party inspections and laboratory testing to independently verify quality claims.

-

Adapt quality expectations to regional regulatory and market requirements, engaging local experts if needed.

-

Establish clear communication channels for continuous quality feedback and improvements.

By thoroughly understanding the manufacturing processes and embedded QA mechanisms, international B2B buyers can confidently source men’s black dress shirts that meet rigorous quality standards, satisfy end-market expectations, and foster long-term supplier partnerships.

Related Video: Amazing Garment Manufacturing Process from Fabric to Finished Product Inside the Factory

Comprehensive Cost and Pricing Analysis for mens black dress shirt Sourcing

Cost Components Breakdown for Mens Black Dress Shirt Sourcing

When sourcing mens black dress shirts for B2B purposes, understanding the key cost components is essential to optimize pricing and negotiate effectively:

-

Materials: This includes fabric (often cotton, polyester blends, or premium textiles), sewing threads, buttons, interlinings (for collars and cuffs), and packaging materials. Fabric accounts for the largest share, typically 40-60% of the total cost, depending on quality and sourcing origin.

-

Labor: Labor costs vary widely by manufacturing location. Countries with established garment industries offer competitive rates, but skilled labor for precision tailoring or complex designs may command higher wages. Labor costs typically range between 15-30% of total production costs.

-

Manufacturing Overhead: Factory utilities, equipment depreciation, maintenance, quality control personnel, and administrative expenses fall under overhead. These costs usually add another 10-20% on top of direct labor and materials.

-

Tooling and Preproduction: Pattern making, sample development, tech pack creation, and cutting dies/tools contribute upfront costs, often amortized over large production runs.

-

Quality Control (QC): Inspection of fabric, trims, in-line sewing checks, and final garment audits are crucial for maintaining standards, especially for export compliance and certifications. QC expenses can be 3-7% of total costs.

-

Logistics and Freight: International shipping, customs duties, insurance, and inland transportation add significant costs. Air freight is faster but more expensive; sea freight is cost-efficient but slower. Logistics typically add 8-15%, varying by Incoterms and destination.

-

Supplier Margin: Manufacturers and suppliers include profit margins, which fluctuate based on order size, client relationship, and market conditions, generally ranging from 10-20%.

Key Price Influencers Impacting Mens Black Dress Shirt Costs

Several factors influence the final pricing of mens black dress shirts, particularly relevant for buyers from Africa, South America, the Middle East, and Europe:

-

Order Volume and Minimum Order Quantity (MOQ): Larger volumes drastically reduce per-unit costs due to economies of scale. Small buyers should anticipate higher unit prices or negotiate consolidated orders.

-

Design Specifications and Customization: Complex patterns, special finishes (e.g., matching stripes or checks), branded labels, and bespoke sizing increase costs.

-

Material Quality and Certifications: Organic or sustainable fabrics, OEKO-TEX or GOTS certifications, and premium trims elevate costs but add brand value and appeal to conscientious markets.

-

Supplier Location and Capabilities: Factories with advanced technology (CAD pattern making, automated cutting) deliver consistent quality but may charge premiums. Proximity to raw material sources can reduce material costs.

-

Incoterms and Payment Terms: FOB, CIF, DDP, and other Incoterms affect who bears shipping and customs costs, influencing the landed cost. Favorable payment terms (e.g., letters of credit) may secure better pricing.

-

Market Demand and Seasonality: Demand fluctuations and global supply chain disruptions can cause price volatility.

Strategic Buyer Tips for Cost-Efficient Sourcing

For international B2B buyers, especially from emerging markets like Kenya and Colombia, the following approaches enhance cost-efficiency and overall procurement success:

-

Negotiate Based on Total Cost of Ownership (TCO): Look beyond unit price to include logistics, import duties, quality assurance, and potential rework costs. TCO analysis helps avoid surprises and supports better supplier selection.

-

Leverage Volume Consolidation: Pooling orders across multiple buyers or product lines can meet MOQs and unlock better pricing tiers.

-

Prioritize Quality Certifications: While higher upfront costs may occur, certified materials and factories reduce risks of returns and reputational damage.

-

Optimize Shipping and Incoterms: Collaborate with suppliers to choose Incoterms that balance cost and risk effectively. For example, CIF terms provide more predictability for buyers new to international trade.

-

Request Transparent Cost Breakdowns: Insist suppliers share detailed cost components to identify savings opportunities and validate quotes.

-

Plan for Lead Times and Sampling: Allocate sufficient time and budget for samples and preproduction approvals to avoid costly errors and delays.

-

Build Long-Term Supplier Relationships: Reliable partnerships can yield preferential pricing, flexible MOQs, and prioritized production slots.

Indicative Pricing Disclaimer

Prices for mens black dress shirts vary widely based on fabric choice, production scale, and sourcing geography. For instance, basic black dress shirts sourced from South Asian factories may range from USD 8 to 15 per unit at large volumes, whereas premium European manufacturers could quote USD 20 and above. Buyers should conduct tailored cost analyses and supplier evaluations to obtain accurate, context-specific pricing.

By comprehensively understanding the cost structure and price influencers, and applying strategic procurement practices, international buyers can secure competitive pricing and high-quality mens black dress shirts that meet their market demands efficiently.

Spotlight on Potential mens black dress shirt Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘mens black dress shirt’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for mens black dress shirt

Critical Technical Properties for Men’s Black Dress Shirts

When sourcing men’s black dress shirts for international B2B trade, understanding key technical specifications is essential to ensure product quality, consistency, and customer satisfaction. Below are the most important technical properties to evaluate:

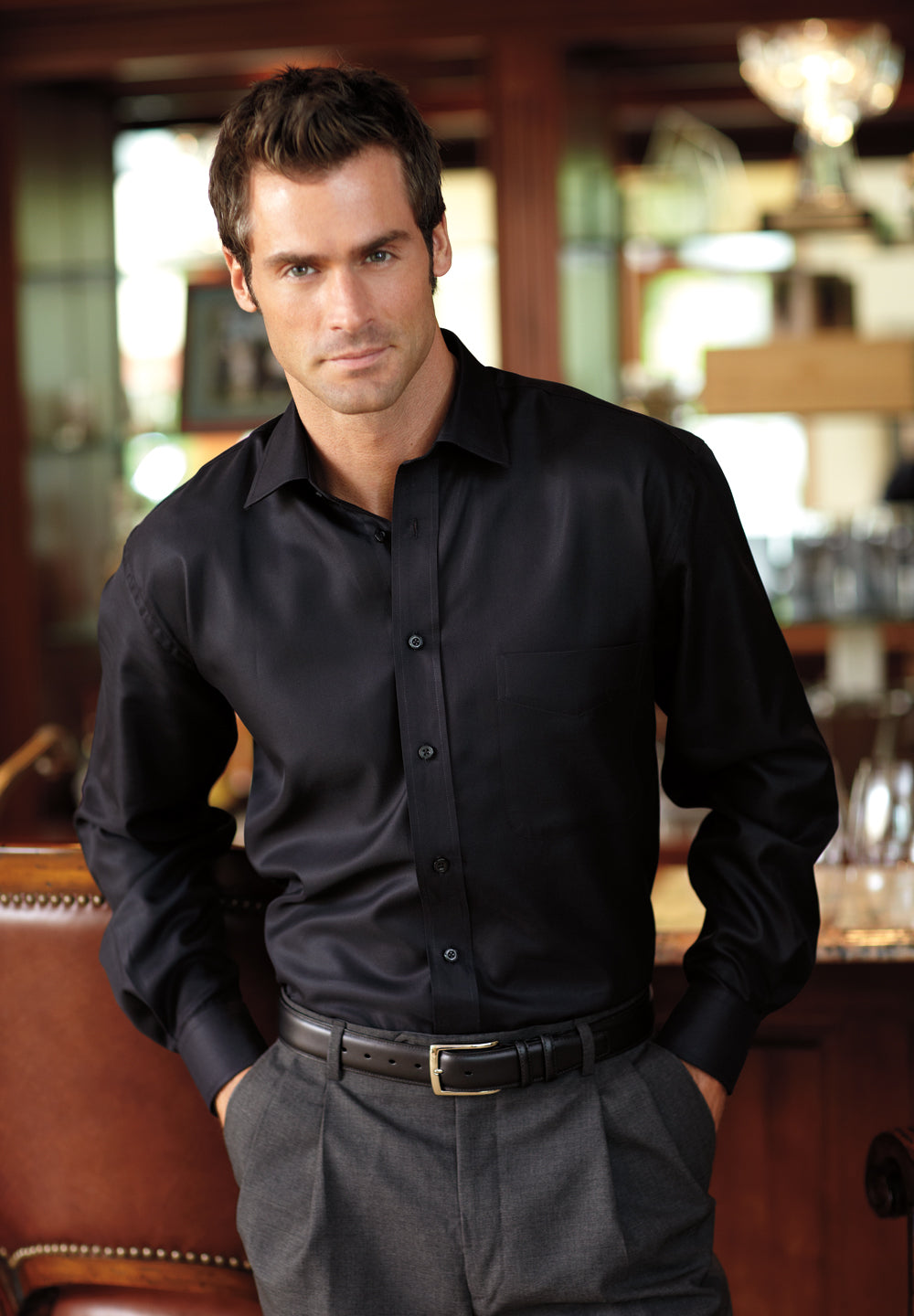

Illustrative Image (Source: Google Search)

-

Fabric Composition and Quality

Typically, black dress shirts are made from cotton, cotton blends, or synthetic fibers. The fiber content (e.g., 100% cotton, cotton-polyester blend) directly affects comfort, durability, breathability, and wrinkle resistance. For B2B buyers, specifying fabric grade (such as combed cotton vs. regular cotton) ensures consistent softness and strength, which impacts end-customer satisfaction and reduces returns. -

Color Fastness and Shade Consistency

Black dye quality and uniformity are critical. Variations in shade can lead to batch inconsistencies, harming brand reputation. B2B buyers should request shade bands and lab test reports for color fastness against washing, light exposure, and rubbing, especially for export markets with strict quality requirements. -

Fabric Weight and GSM (Grams per Square Meter)

Fabric weight affects the shirt’s feel and appropriateness for climates. A typical men’s dress shirt fabric weight ranges from 100 to 160 GSM. Lightweight fabrics suit hot climates (e.g., Kenya, Colombia), while heavier fabrics may be preferred in cooler regions (e.g., Europe). Understanding GSM helps buyers match product offerings to their target market demands. -

Construction and Stitch Density

Stitch density (stitches per inch) influences garment durability and aesthetics. Higher stitch density (e.g., 10-12 stitches per inch) generally means stronger seams and a more refined finish. This technical detail is vital for buyers seeking longevity and premium appearance, especially for formalwear. -

Fit and Pattern Grading Accuracy

Accurate pattern grading for multiple sizes ensures consistent fit across size ranges (S, M, L, XL). B2B buyers should verify that suppliers provide graded tech packs and sample approvals to avoid fit issues that lead to customer dissatisfaction. -

Trims and Accessories Quality

Button materials (plastic, mother-of-pearl), collar interlinings, and thread types impact the shirt’s overall quality and cost. Buyers should specify trim standards and request samples to confirm that accessories match brand positioning and durability expectations.

Key Trade Terminology in Men’s Black Dress Shirt Procurement

Understanding industry jargon is crucial for smooth communication and negotiation between international buyers and manufacturers:

-

OEM (Original Equipment Manufacturer)

Refers to factories that produce shirts according to a buyer’s specifications and branding. OEM relationships allow buyers to maintain control over design, quality, and labeling, essential for private label or branded collections. -

MOQ (Minimum Order Quantity)

The smallest number of units a supplier is willing to produce in one order. MOQs can vary widely depending on factory capacity and product complexity. Buyers, especially startups or SMEs in Africa and South America, should negotiate MOQ to balance inventory risk and cost efficiency. -

RFQ (Request for Quotation)

A formal document sent by buyers to suppliers asking for price, lead time, and terms based on detailed product specifications. A well-prepared RFQ accelerates supplier evaluation and ensures all parties have clear expectations on technical and commercial terms. -

Incoterms (International Commercial Terms)

Standardized trade terms (e.g., FOB, CIF, EXW) defining responsibilities for shipping, insurance, and customs clearance between buyer and seller. Understanding Incoterms is vital for managing cost, logistics, and risk in cross-border transactions. -

Tech Pack

A comprehensive document including detailed design specs, measurements, fabric info, trims, and construction guidelines. Supplying an accurate tech pack minimizes errors and streamlines production, especially when working with offshore manufacturers. -

Shade Band

A grouping of fabric rolls dyed to the same color intensity. Shade bands are used to prevent visible color variation within a batch. Buyers should insist on shade band compliance to ensure uniformity in black dress shirts, which is critical for formal wear.

By focusing on these technical properties and trade terms, B2B buyers can make informed purchasing decisions, reduce quality risks, and foster effective partnerships with manufacturers across Africa, South America, the Middle East, and Europe. Clear communication and precise specifications are the cornerstones of successful international garment sourcing.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the mens black dress shirt Sector

Market Overview & Key Trends

The global market for men’s black dress shirts is influenced by a combination of fashion trends, technological advancements, and shifting consumer preferences. Black dress shirts remain a staple in formal and semi-formal menswear across diverse regions, including Africa, South America, the Middle East, and Europe. For B2B buyers in these markets, understanding regional demand nuances and supply chain complexities is critical.

Illustrative Image (Source: Google Search)

Key Market Drivers:

- Rising Formal Wear Demand: Urbanization and professionalization in emerging economies such as Kenya and Colombia are driving demand for versatile formal wear. Black dress shirts are favored for their adaptability in corporate, hospitality, and event settings.

- E-commerce and Digital Platforms: The proliferation of digital B2B marketplaces facilitates direct sourcing from manufacturers worldwide, increasing competition and transparency. Buyers can leverage these platforms to access new suppliers and negotiate better terms.

- Customization & Fit Innovation: Advances in pattern making and CAD technologies enable manufacturers to offer size grading and made-to-measure options efficiently. This trend aligns with growing consumer expectations for tailored fit and comfort.

- Fabric Innovation: Incorporation of performance fabrics with wrinkle resistance, moisture wicking, and stretch enhances appeal in hot and humid climates common in many African and Middle Eastern markets.

- Supply Chain Localization: Buyers increasingly seek suppliers closer to their markets or those with flexible production capacities to reduce lead times and manage costs amid global disruptions.

Emerging B2B Sourcing Trends:

- Integrated Tech Systems: Manufacturers adopting ERP and production management software improve order tracking, quality control, and communication, enabling buyers to monitor production progress in real-time.

- Sourcing from Sustainable Mills: There is a visible shift towards sourcing fabrics from suppliers who offer organic cotton, recycled polyester, or eco-friendly dyeing processes, responding to growing sustainability demands.

- Small Batch & Agile Production: To mitigate inventory risks, international buyers prefer manufacturers capable of small batch runs and quick sampling cycles.

Understanding these dynamics helps B2B buyers from regions like South America and Europe optimize procurement strategies, balancing cost, quality, and delivery reliability.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a cornerstone of the men’s black dress shirt supply chain, driven by regulatory pressures, consumer awareness, and corporate responsibility commitments. For international B2B buyers, integrating sustainability into sourcing decisions is no longer optional but a strategic imperative.

Environmental Impact Considerations:

- Water and Chemical Usage: Traditional cotton cultivation and dyeing processes are water-intensive and involve toxic chemicals. Opting for suppliers who implement low-impact dyeing techniques, such as digital printing or natural dyes, significantly reduces environmental footprints.

- Waste Reduction: Fabric cutting optimization using CAD-based marker making minimizes textile waste. Manufacturers adopting zero-waste cutting or recycling offcuts contribute to circular economy goals.

- Energy Efficiency: Factories investing in renewable energy sources and energy-efficient machinery lower carbon emissions associated with production.

Ethical Supply Chain Importance:

- Labor Standards: Ensuring factories comply with fair labor practices, including safe working conditions and fair wages, is critical. Certifications such as WRAP (Worldwide Responsible Accredited Production) or SA8000 provide buyers with assurance.

- Transparency & Traceability: Blockchain and digital tracking technologies enable end-to-end supply chain visibility, helping buyers verify ethical claims and respond to compliance audits effectively.

Green Certifications & Sustainable Materials:

- Organic Cotton & Recycled Fibers: Fabrics certified by GOTS (Global Organic Textile Standard) or made from recycled fibers (e.g., recycled polyester) are preferred for their lower environmental impacts.

- OEKO-TEX Standard 100: This certification assures textiles are free from harmful substances, aligning with buyer and consumer health priorities.

- Bluesign® System: Ensures sustainable textile production by controlling chemical inputs and environmental emissions during manufacturing.

For buyers in markets like the Middle East and Africa, prioritizing suppliers with verifiable sustainability credentials supports brand differentiation and compliance with increasingly stringent import regulations.

Brief Evolution of the Men’s Black Dress Shirt in B2B Context

The men’s black dress shirt has evolved from a niche formalwear item to a versatile wardrobe essential with broad B2B appeal. Historically associated with evening wear and subcultures, it gained mainstream acceptance through fashion cycles emphasizing minimalist and monochrome aesthetics.

In the B2B landscape, this evolution is marked by the transition from bespoke tailoring to mass production facilitated by industrial sewing lines and CAD pattern grading. This shift enabled manufacturers to cater to growing global demand efficiently, especially in emerging markets.

Today, the black dress shirt symbolizes professionalism and style adaptability, driving demand from corporate uniform suppliers, retail chains, and private label brands. The ongoing integration of sustainable materials and digital manufacturing technologies continues to redefine sourcing and production strategies for international buyers.

Related Video: International Trade Explained

Frequently Asked Questions (FAQs) for B2B Buyers of mens black dress shirt

-

How can I effectively vet suppliers of men’s black dress shirts for international B2B sourcing?

To vet suppliers, start by reviewing their certifications such as ISO, OEKO-TEX, or WRAP, which indicate compliance with quality and ethical standards. Request detailed product samples to assess fabric quality, stitching, and finishing. Verify their production capacity and lead times through references or third-party audits. Check their experience exporting to your region (Africa, South America, Middle East, Europe) to ensure familiarity with local regulations. Additionally, evaluate communication responsiveness and transparency regarding material sourcing and manufacturing processes to minimize risks. -

What customization options are typically available for bulk orders of men’s black dress shirts?

Most manufacturers offer customization including fabric type (cotton, blends), collar styles (spread, button-down), cuff designs (single, double), and fit options (slim, regular). You can also request custom branding such as labels, packaging, and embroidery. For international buyers, it’s important to clarify minimum order quantities (MOQs) for customized orders as they tend to be higher. Early engagement with suppliers on design tech packs and samples is critical to ensure specifications are met and reduce costly revisions during production. -

What are typical MOQs and lead times for men’s black dress shirt orders from international suppliers?

MOQs vary widely depending on the factory scale but typically range from 300 to 1000 pieces per design or size mix. Lead times can span from 45 to 90 days, factoring in fabric sourcing, sampling, production, and quality checks. Buyers from regions like Kenya or Colombia should also consider additional shipping and customs clearance time. Negotiating MOQs and lead times upfront, and requesting a clear production timeline, helps align expectations and supports timely inventory planning.

Illustrative Image (Source: Google Search)

-

Which payment terms are standard in international B2B transactions for men’s black dress shirts?

Common payment terms include a 30% deposit upfront with the balance paid upon shipment or after inspection. Letters of Credit (LC) and escrow services are also popular to secure funds and reduce risk for both parties. For new supplier relationships, consider smaller initial orders with secure payment methods to build trust. It’s advisable to clarify payment currency and any associated transaction fees upfront to avoid surprises. -

How can I ensure quality assurance when sourcing men’s black dress shirts internationally?

Quality assurance starts with detailed tech packs specifying fabric weight, colorfastness, stitch density, and sizing standards. Request pre-production samples and conduct third-party inspections during and after production. Many factories provide quality control certificates or compliance reports on request. For buyers in Africa or South America, partnering with local inspection agencies can help verify quality and compliance with import regulations before shipment. -

What certifications should I look for in suppliers of men’s black dress shirts to meet international standards?

Look for certifications like ISO 9001 for quality management, OEKO-TEX Standard 100 for harmful substances, and WRAP or BSCI for social compliance. These certifications indicate adherence to environmental, safety, and ethical manufacturing practices, which are increasingly important to European and Middle Eastern markets. Verifying these certifications helps mitigate reputational risks and ensures your products meet buyer expectations in diverse global markets. -

What logistics considerations should I keep in mind when importing men’s black dress shirts from overseas?

Consider shipping modes (sea freight for cost efficiency or air freight for speed), customs clearance procedures, and potential tariffs or import duties specific to your country. Accurate product classification under HS codes ensures correct duty assessment. Work with freight forwarders experienced in your region (e.g., East Africa, South America) to manage documentation and delivery schedules. Also, factor in packaging requirements to prevent damage during transit and optimize container space. -

How should I handle disputes or quality issues with international suppliers of men’s black dress shirts?

Establish clear contractual terms covering quality standards, inspection rights, and remedies for defects before production begins. Maintain detailed records of communications, samples, and quality reports. If issues arise, initiate dialogue promptly to seek amicable resolutions such as rework, discounts, or replacements. For persistent disputes, use mediation or arbitration clauses stipulated in contracts. Engaging legal counsel familiar with international trade law relevant to your sourcing country can provide additional protection.

Strategic Sourcing Conclusion and Outlook for mens black dress shirt

Strategic sourcing of men’s black dress shirts demands a nuanced understanding of garment manufacturing—from fabric procurement and pattern making to cutting, stitching, and finishing. For international B2B buyers in Africa, South America, the Middle East, and Europe, prioritizing suppliers who demonstrate rigorous quality control, efficient production workflows, and adaptability to bespoke sizing and design requirements is crucial. Leveraging factories that integrate technology like CAD for pattern grading and automated cutting can significantly enhance consistency and reduce lead times.

Key takeaways for buyers include:

- Partnering with manufacturers that ensure thorough material inspection to minimize defects and shade variation, thereby delivering premium quality.

- Emphasizing transparent communication during pre-production phases, including fabric development and tech pack finalization, to align expectations and reduce costly revisions.

- Considering sustainable and ethical sourcing practices as differentiators that appeal to global markets increasingly focused on responsible consumption.

Looking ahead, the menswear market will continue to evolve with rising demand for customization and eco-conscious production. Buyers from Colombia, Kenya, and beyond are encouraged to cultivate strategic supplier relationships that balance innovation with cost-efficiency. By doing so, they position themselves to meet diverse market needs while driving growth in the competitive landscape of men’s black dress shirts. Now is the time to leverage insights and technology-driven sourcing to secure reliable, scalable partnerships for the future.